Live steam, Technology, Steam injection humidifiers – Nortec Industries Pressure Steam Humidifier User Manual

Page 4

technology

1

9

7

5

6

4

2

10

3

8

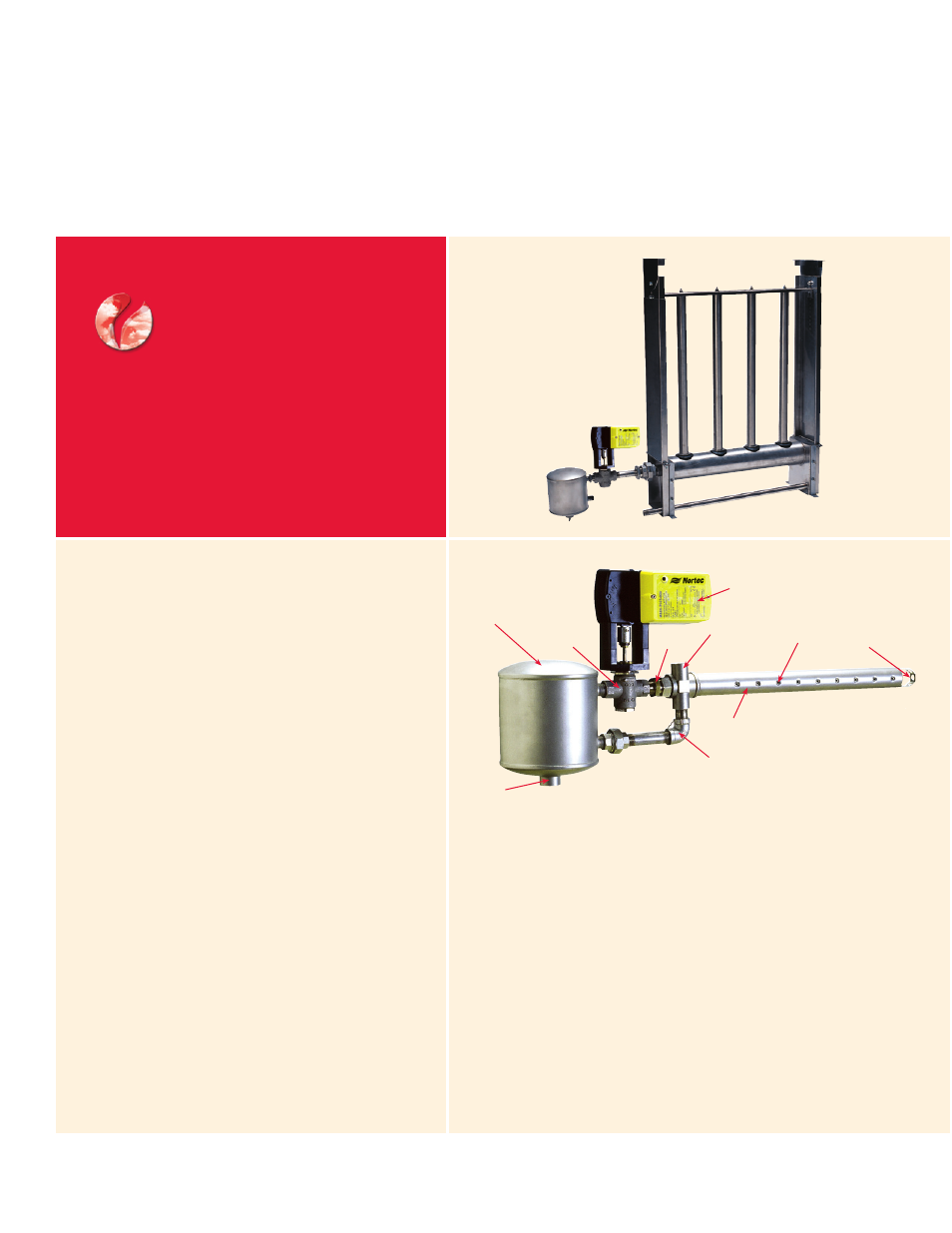

1

Steam inlet, strainer upstream to

remove impurities.

2

Steam jacketed dispersion tube.

3

Tube support bracket, ensures

proper unit installation.

4

Interconnecting pipes between

dispersion tube and separator.

5

Steam separator ensures only

condensate-free steam is

discharged into the air stream.

6

Condensate outlet to steam trap

for recirculation to boiler for

energy efficient operation.

7

Steam control valve meters

steam entering dispersion tube.

8

Electric on/off and electric

modulating actuators standard.

Pneumatic valve actuator optional.

9

Tube adaptor connecting valve to

dispersion tube. Factory installed

silencers are available.

10

Steam outlet orifices sized for

exact humidity output.

LiveSteam mounted

with a SAM-e manifold

for short absorption

distance applications

Available for single or

multiple tube applications

Pressure ranges from

-50 PSIG

High capacity system

(up 309 lbs/hr)

Economical and cost effective

system to meet high humidity

requirements

Delivers precise humidity

control

Steam jacketed dispersion

tubes to prevent wetting

Support brackets on tubes

over feet in length

Available for regular or purified

boiler steam

Available for pneumatic or

electric controls

▶

▶

▶

▶

▶

▶

▶

▶

▶

Live

Steam

®

Steam

Injection

Humidifiers

4