Powermatic DDS-225 User Manual

Page 3

OWERMATIC

lowered on four jackscrews turned simultaneously by a slip-free chain

drive. That chain drive also

keeps the table level at all

heights. The chain drive has

an automatic tensioning

system built in to reduce

setup and adjustment. The

table height system is

operated by a large cast iron

handwheel at the top of the

POWERMATIC Dual

Drum Sanders. An easy-to-

read depth gauge next to the

table makes presetting table

for specific material

thicknesses easy.

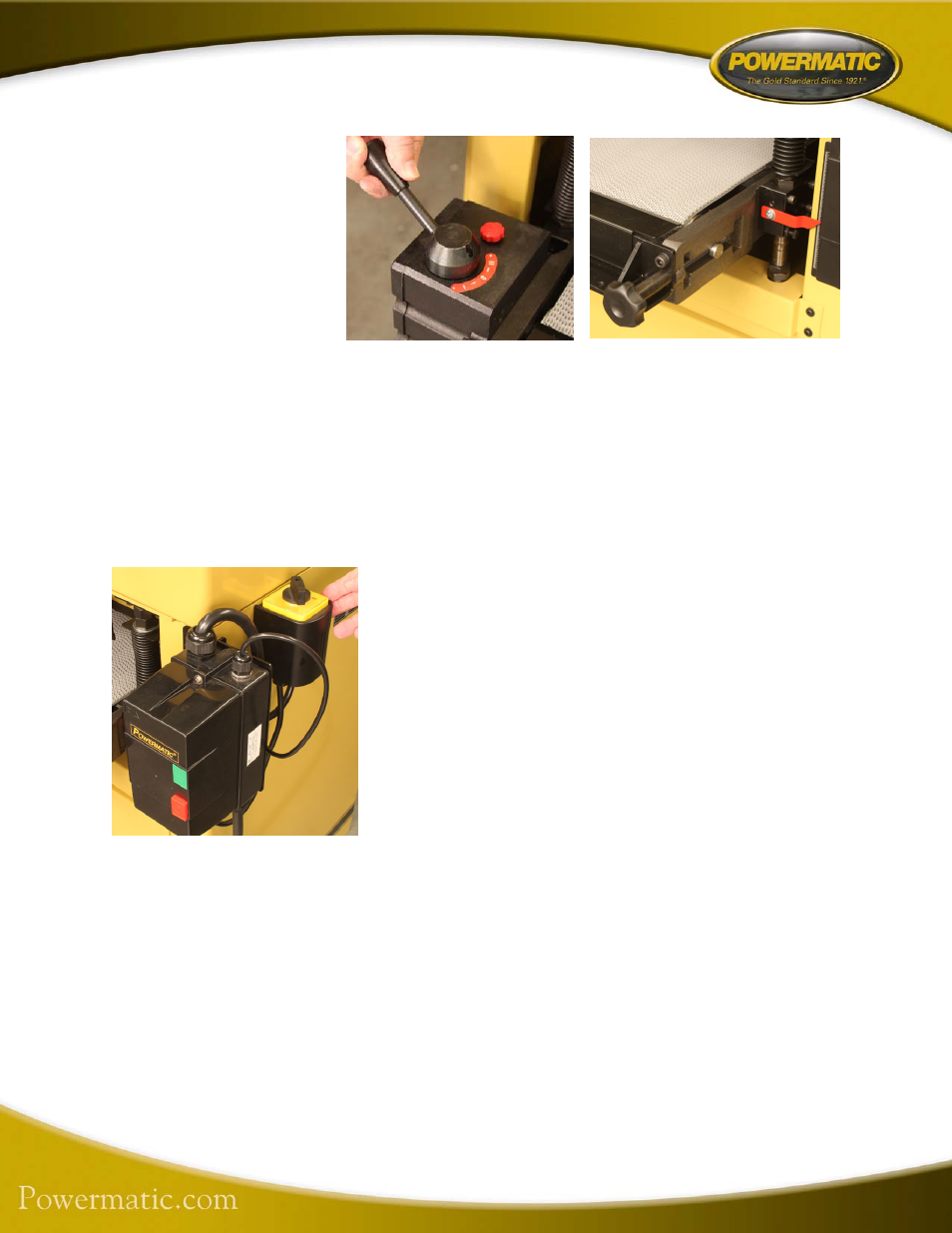

The conveyor is driven by a two-speed gearbox (left) that is shifted while the belt is

running. Each side of the conveyor has an easy adjuster (right) for belt tracking and

tension

The heavy-duty poly conveyor belt provides a positive grip on the material being sanded. The

high-quality conveyor belt has tracking adjusters at either end of the table. These adjusters also

control belt tension.

The 1/4HP feed motor drives the conveyor belt and is

controlled by a two-speed forward/reverse gearbox that

produces feed rates of 8 and 12 SFPM (surface feet per

minute). The gearbox can only be shifted between the low

and high feed rates while the machine is running. The

conveyor belt can also be reversed, using a separate three-

position switch with forward, off and reverse positions.

Reversing can be handy in the event that a problem

develops, the belt can be reversed to safely bring the piece

back out. That lets you correct the problem more easily.

Industrial-tough controls, including a full

magnetic switch protect the

POWERMATIC Dual Drum Sanders.

The POWERMATIC Dual Drum Sanders are designed with

the industrial environment in mind. They are tough, easy to

use and easy to maintain. Their wide capacity ranges mean

one machine handles more jobs, making the P

Dual Drum Sanders a very cost-effective investment.