Cutting the tails, 30 fig. 53c, Fig. 53a – Porter-Cable 4212 User Manual

Page 30: Fig. 52b, Fig. 52a, Fig. 53b

30

Fig. 53C

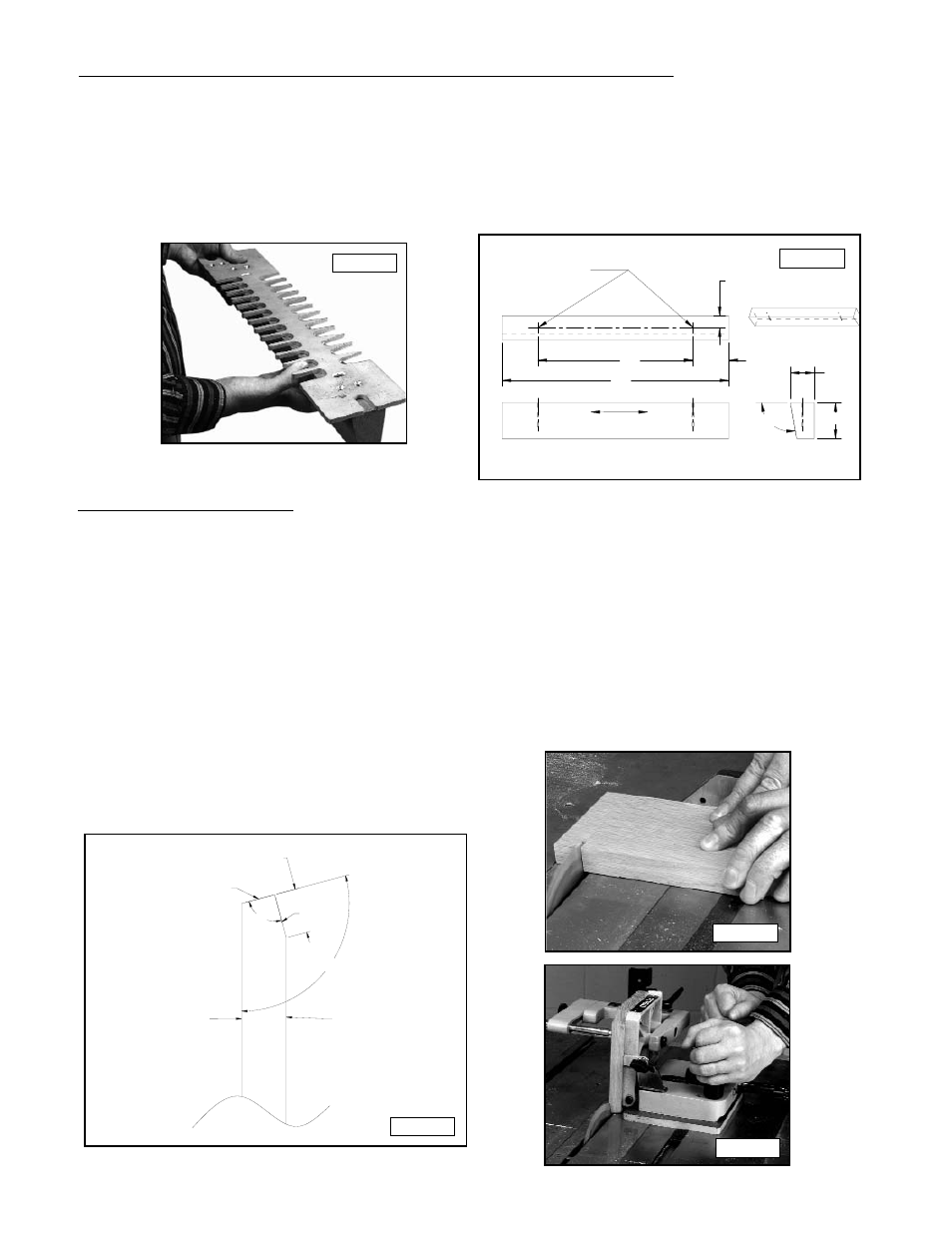

Cut the end of the tail board according to the instructions in the drawing (Fig. 53A). You can make these

cuts on a table saw with the blade beveled (Fig. 53B). Set the miter gauge at 90° for the first cut, then use

a tenoning jig for the second cut (Fig. 53C).

If you use the template mounted to the base of the jig, mount the board with the outside face toward the

base of the jig. Center the edges of the board between two fingers (Fig. 53D).

If you use the board-mounted template, clamp the board with the outside face toward the angled surface

of the clamping board. Center the board between two fingers.

Align the template using the “tails” line.

If the angle is steep, the “tails” line may not align with the wood. The joint will be fine if you place the straight

portion of the template fingers directly over the tail board (A) Fig. 53E. Otherwise, you may have to use an

angled clamping board.

Set the router bit depth where the sides of the board are at a slight angle (Fig. 53F).

Cut the tails and remove the tail board.

Step 1 -

Step 2 -

Step 3 -

Step 4 -

Step 5 -

Step 6 -

Step 7-

CUTTING THE TAILS

OUTSIDE

SURFACE

OF BOARD

FIRST CUT

SECOND CUT

INSIDE

SURFACE

OF BOARD

90°

ANGLE BETWEEN BOARDS

THICKNESS OF PIN BOARD

Fig. 53A

WOOD GRAIN

DRILL PILOT HOLES

FOR #10 WOOD SCREWS

"

13

"

3

"

1

"

19

"

2

"

3

ANGLE OF

BOARDS

Fig. 52B

SETUP WITH THE TEMPLATE MOUNTED TO A CLAMPING BOARD

Fig. 52A

Make an angled clamping board according to the drawing (Fig. 52B). Match the angle of the

clamping board to the joint angle.

If necessary, create flat places on the clamping board parallel with the opposite side so that the

clamps can grab.

Attach the template to the clamping board with #10 wood screws. Position the angled surface on

the side of the template with the straight fingers (Fig. 52A).

Step 1 -

Step 2 -

Step 3 -

Fig. 53B