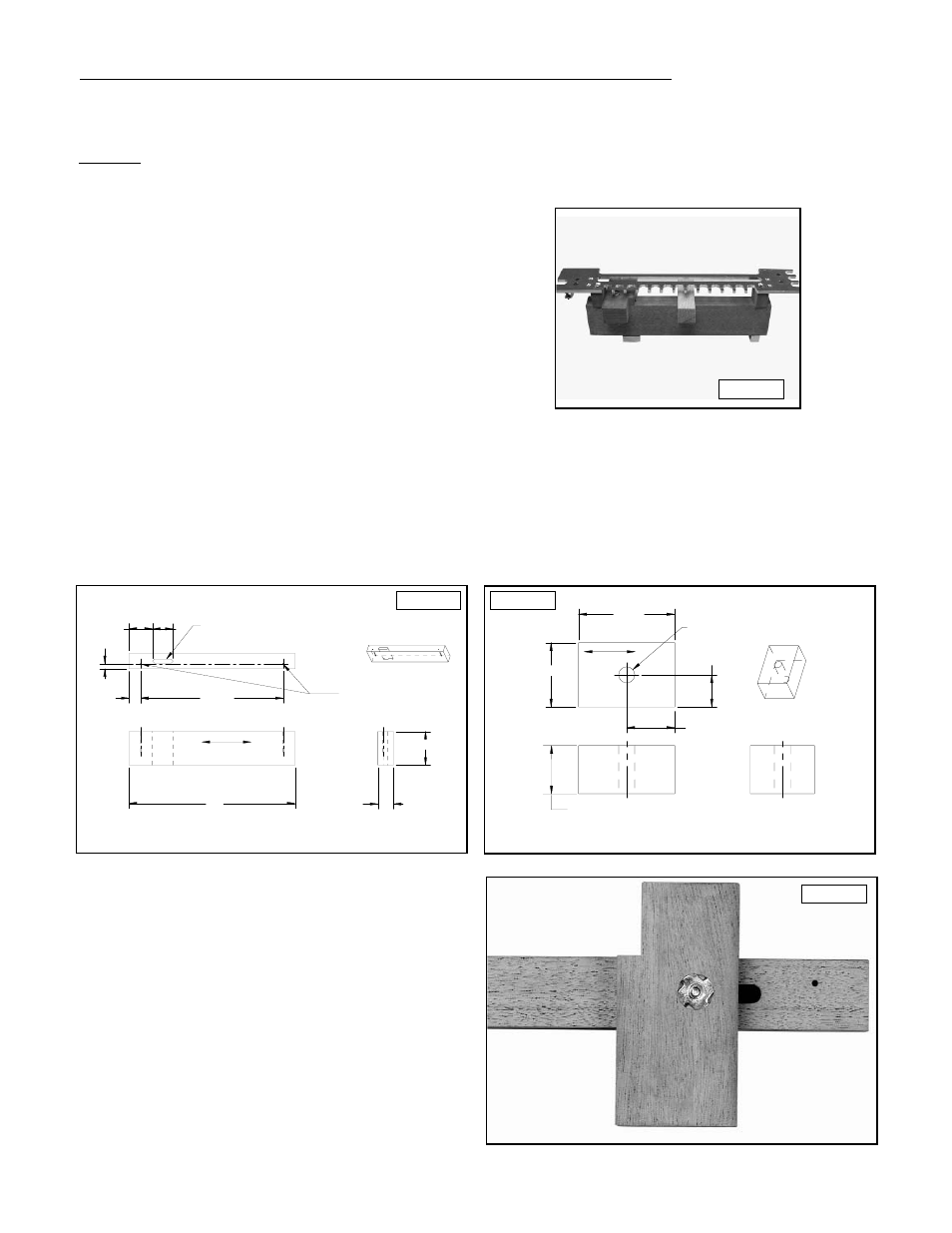

Half-blind dovetails with clamping boards, Setup, Fig. 14a – Porter-Cable 4212 User Manual

Page 11: Fig. 15a fig. 15b, Fig. 15c

11

HALF-BLIND DOVETAILS WITH CLAMPING BOARDS

You can mount your half-blind template that comes with the 4210 and 4212 jigs and the 4211 accessory kit to a

board. This method, however, limits your workpiece width capacity to 8".

SETUP

Items needed to setup for the half-blind dovetails:

1.

Wood to make the clamping board parts

2.

Clamps

3.

2" #10 wood screws (2)

4.

1/4-20 threaded T-nut

5.

1/4-20 x 4" bolt

6.

1/4" washer

NOTE: These instructions can be modified for making half-

blind dovetails with the through dovetail template and for

the miniature dovetail template (See the section “HALF-

BLIND DOVETAILS WITH TAIL BOARDS THICKER THAN

7/8").

Fig. 14A

MAKE THIS DIMENSION THE

THICKNESS OF THE PIN BOARD

THAT IS TO BE DOVETAILED

MAKE TWO OF THESE BLOCKS

WOOD GRAIN

"

1

"

1-1/2

"

1/2

"

3/4

DRILL A

" HOLE

THROUGH THE BLOCK

1/4

WOOD GRAIN

3/8" WIDE MORTISE GOES

THROUGH BLOCK. MORTISE

IS CENTERED ON BLOCK.

DRILL PILOT HOLES

FOR #10 WOOD SCREWS

"

1-1/2

"

3-1/4

"

16

"

2

"

2-1/4

"

13-3/4

"

1-1/8

"

1/2

Fig. 15A

Fig. 15B

Make a main clamping board 1-1/2" x 3-1/4" x 16". Square all of the sides. Make a mortise

through the board and drill pilot holes for #10 wood screws (Fig. 15A).

NOTE: Threaded inserts and #10 flathead machine screws can be used in place of the #10

wood screws.

Make the offset clamping block. Make a counterbore for the threaded T-nut (Fig. 15B).

NOTE: If your pin board is thinner than 3/4", modify the dimension. You may need to use extra

washers to prevent the bolt from sticking out.

Step 1 -

Step 2 -

Fig. 15C

Insert the threaded nut into the offset clamping

block (Fig. 15C).

Step 3 -