Progressive Turf Equipment SDR 90 User Manual

Page 22

22

“V”

BELT

ADJUSTMENT:

Begin by loosening 4 bolts at the base of the gearbox.

Adjusting long

threaded bolt slides the gearbox back, tightening belt.

After proper tension is

ac

hi

e

ved,

t

i

ght

e

n

4

bol

t

s

a

t

ba

s

e

of

gea

r

box.

You

may

have

t

o

pl

a

c

e

a

½”

nut

unde

r

the head of the long threaded bolt to increase your adjustment length.

When changing belts, removal of grease fitting from the top of the center

spindle will make installation easier. Be sure belts run in proper groove.

“V”

BELT

TENSI

ON:

Proper belt tensioning is a fundamental factor in the successful V-belt

operation. Lack of tension will cause slippage, and too much tension will cause

excessive belt stretch as well as damage to the drive components, such as bearings

and shafts. Therefore, to ensure proper belt tension, the following procedure is

recommended.

CHECKING BELT TENSION

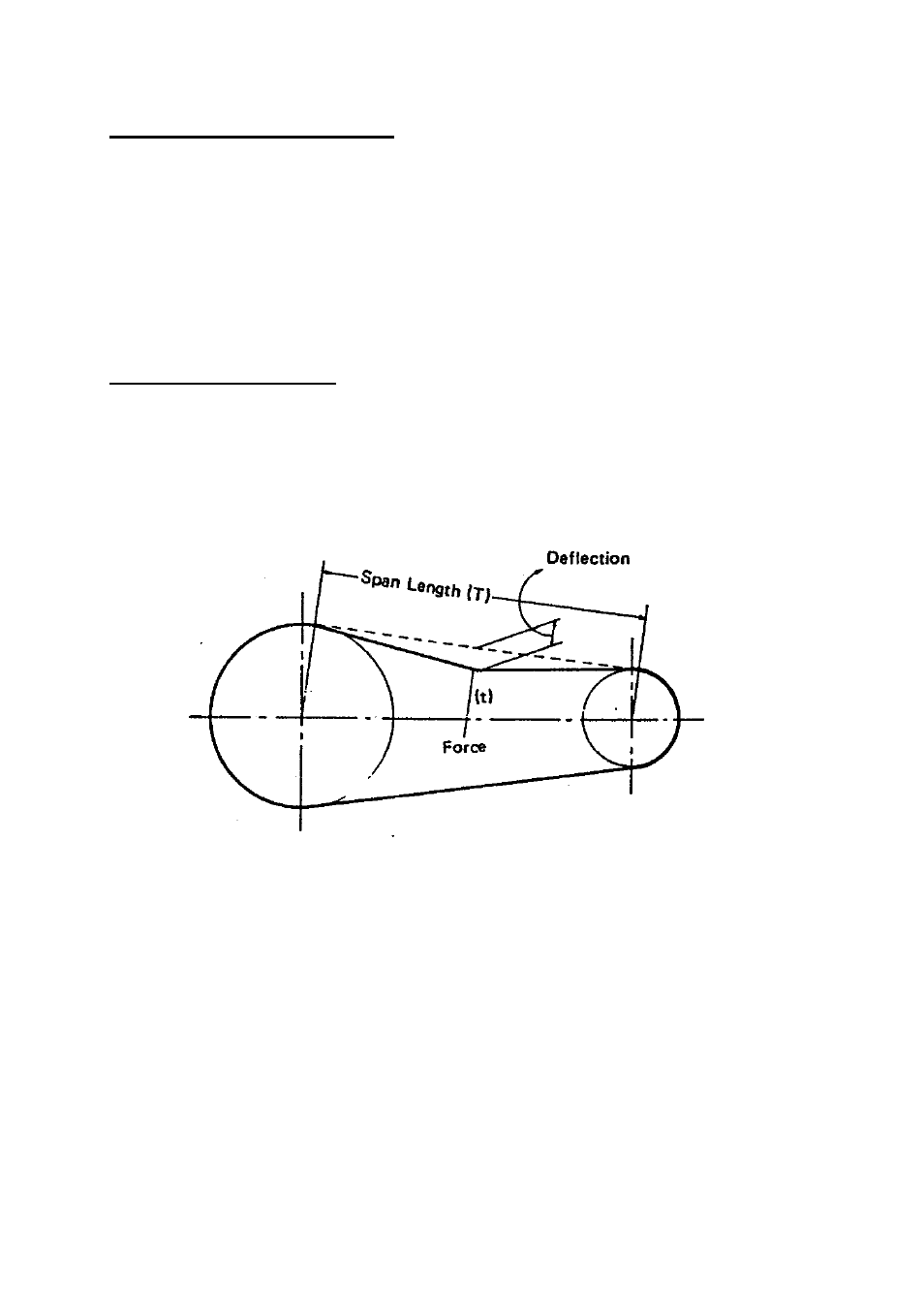

At the mid-point of the span, apply a deflection force with a spring scale in

t

he

di

r

ec

t

i

on

per

pe

ndi

c

ul

ar

t

o

t

he

s

pa

n

unt

i

l

t

he

be

l

t

i

s

de

f

l

e

ct

e

d

t

he

3/

8”

.

The recommended force to deflect the belt is a minimum of 4.9 lbs. to a maximum

of 7.3 lbs.

The

f

i

r

s

t

24

t

o

48

hour

s

of

oper

a

t

i

on

i

s

t

he

be

l

t

“

r

un

i

n”

pe

r

i

od.

To

e

ns

ur

e

satisfactory belt performance, belt tension should be checked during this time

period.