Caution, Preinstallation – PB Heat EC Series User Manual

Page 5

3

C. CHIMNEY / VENT AND DRAFT CONTROL

1. Draft Requirement – Minimum draft required in the

vent system is -.03" to -.05" W.C. depending on

boiler model, see Table 7.1 (Section 7). This draft is

necessary to provide the necessary draft over fire of

-.01" to -.02" W.C. See discussion in paragraph 5

below regarding draft.

2. Use barometric provided to control draft. Follow

manufacturer's instructions to locate and adjust the

control.

3. Inspect the existing chimney or vent system. Make

sure it is in good condition. Inspect chimney liner

and repair or replace if necessary.

4. The vent system and installation must be in

accordance with the current edition of the American

National Standard ANSI/NFPA 211, "Chimneys,

Fireplaces, Vents, and Solid Fuel Burning

Appliances," or applicable provisions of the local

building codes. See Table 7.1 (Section 7) for typical

chimney size. If the vent system is not sized properly,

the burner may not operate properly. This can cause

poor combustion, sooting and odors to occur.

5. Background Information Regarding Draft:

Modern boilers operate with higher efficiencies than

older boilers. Smaller flueways, as well as bars, pins

and fins are designed into modern boilers to transfer

as much heat as possible from the hot gases to the

water or steam and prevent heat loss up the

chimney. However, these design features result in

higher pressure, or draft loss, in the boiler.

This draft loss must be taken into account when

installing an oil boiler into a new or old chimney.

New chimneys are less likely to have poor draft.

However, they must have sufficient draft to support

combustion. A -.06" draft is desirable and preferred.

Older chimneys may require a replacement liner to

have them perform well enough to support

combustion.

For Example:

The above readings are "cold" readings (before the

boiler and chimney are heated up).

Note also that the higher the firing rate on a unit

which has multiple firing rates, the higher the draft

required. For example, increasing the firing rate 1/4

gallon may increase the draft loss in a unit by

approximately +.01".

D. INSTALLATION SURVEY

For new and existing installations, a Water Installation

Survey or a Steam Installation Survey is available from

P.B. Heat, LLC. The surveys will provide information on

how the boiler works with your specific system and will

provide an overview of boiler system operation in

general.

You can also use this survey to locate system problems

which will have to be corrected. To obtain copies of

these Surveys, contact your PB Heat representative or

download it from PeerlessBoilers.com.

E. PLANNING THE LAYOUT

Prepare sketches and notes of the layout of the

installation. Include boiler location, venting system,

existing piping and wiring. Show existing equipment that

may interfere with installation of new equipment.

An oil-fired unit shall be connected

to a flue having sufficient draft at all

times, to assure safe proper

operation of the unit.

CAUTION

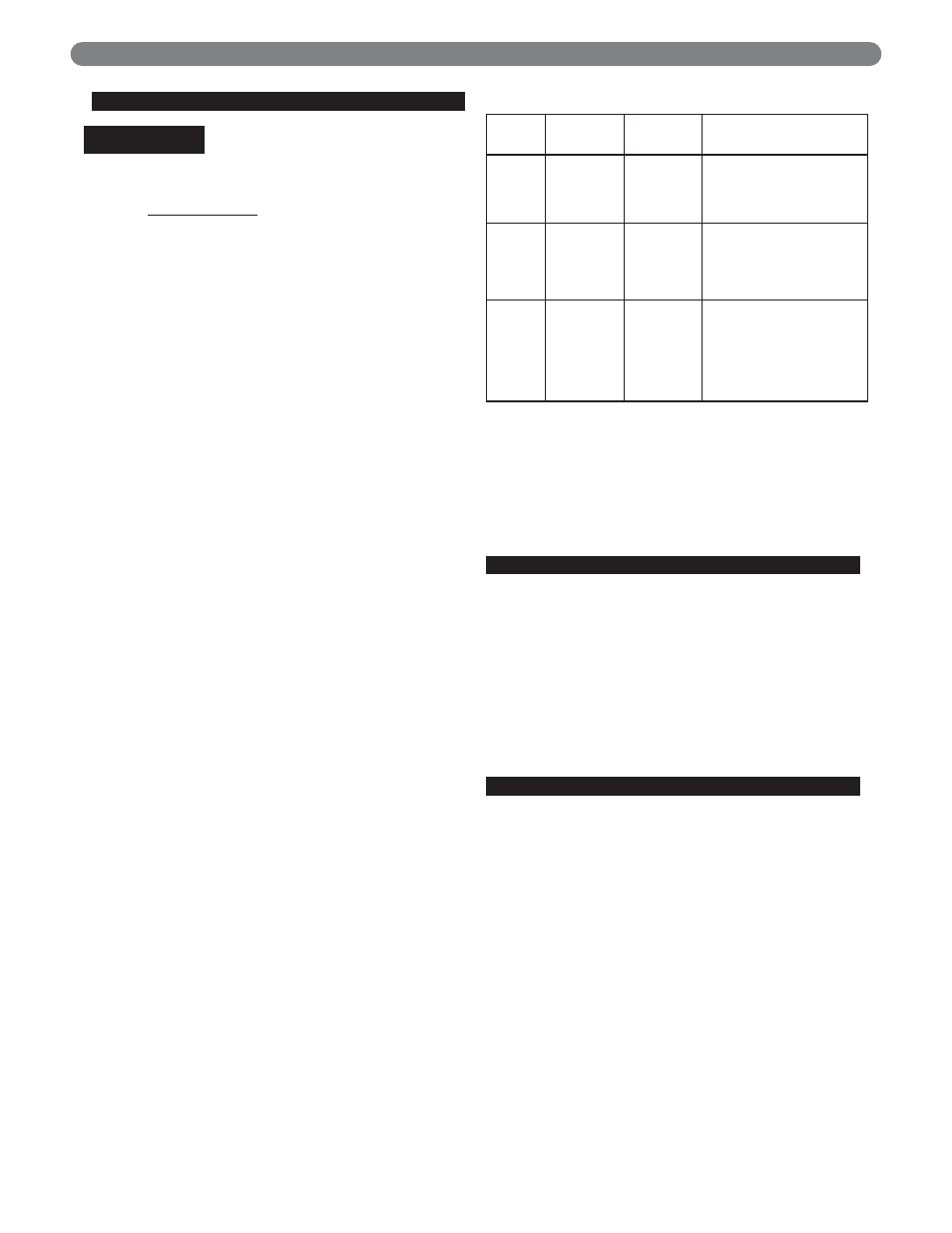

Old

Installation

New

Installation

Comments

Chimney

Draft

-.04"

-.04"

No change, but older

chimneys (especially unlined

ones) have leaks which

reduce draft.

Boiler

Design

Pressure

Drop

+.01"

+.04"

Required for mandated

efficiency increases.

Draft

Over Fire

-.03"

0.00"

The old installation would

have had a higher

temperature in the chimney

[as high as 800 degrees vs.

400 degrees F], which would

increase the draft.

PREINSTALLATION