Grounding instructions, Adjustments – Powermatic PM2000 User Manual

Page 14

14

Grounding Instructions

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded to help prevent electrical

shock and possible fatal injury.

A power plug is not provided with the Model 2000.

You may either connect the proper UL/CSA listed

plug or “hardwire” the machine directly to your

electrical panel provided there is a disconnect near

the machine for the operator. Consult electrical

drawings on pages 37-39 for further clarification of

wiring setup.

This machine must be grounded. Grounding

provides a path of least resistance to help divert

current away from the operator in case of electrical

malfunction.

Make sure the voltage of your power supply

matches the specifications on the motor plate of the

machine.

Extension Cords

If an extension cord is necessary, make sure the

cord rating is suitable for the amperage listed on

the machine's motor plate. An undersize cord will

cause a drop in line voltage resulting in loss of

power and overheating.

The chart in Table 1 shows the correct size cord to

use based on cord length and motor plate amp

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Amps

Extension Cord Length *

25

feet

50

feet

75

feet

100

feet

150

feet

200

feet

<

5

16 16 16 14 12 12

5

to

8 16 16 14 12 10 NR

8 to 12

14

14

12

10

NR

NR

12

to

15 12 12 10 10 NR NR

15 to 20

10

10

10

NR

NR

NR

21

to

30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the

rated amperes.

NR: Not Recommended.

Table 1

Adjustments

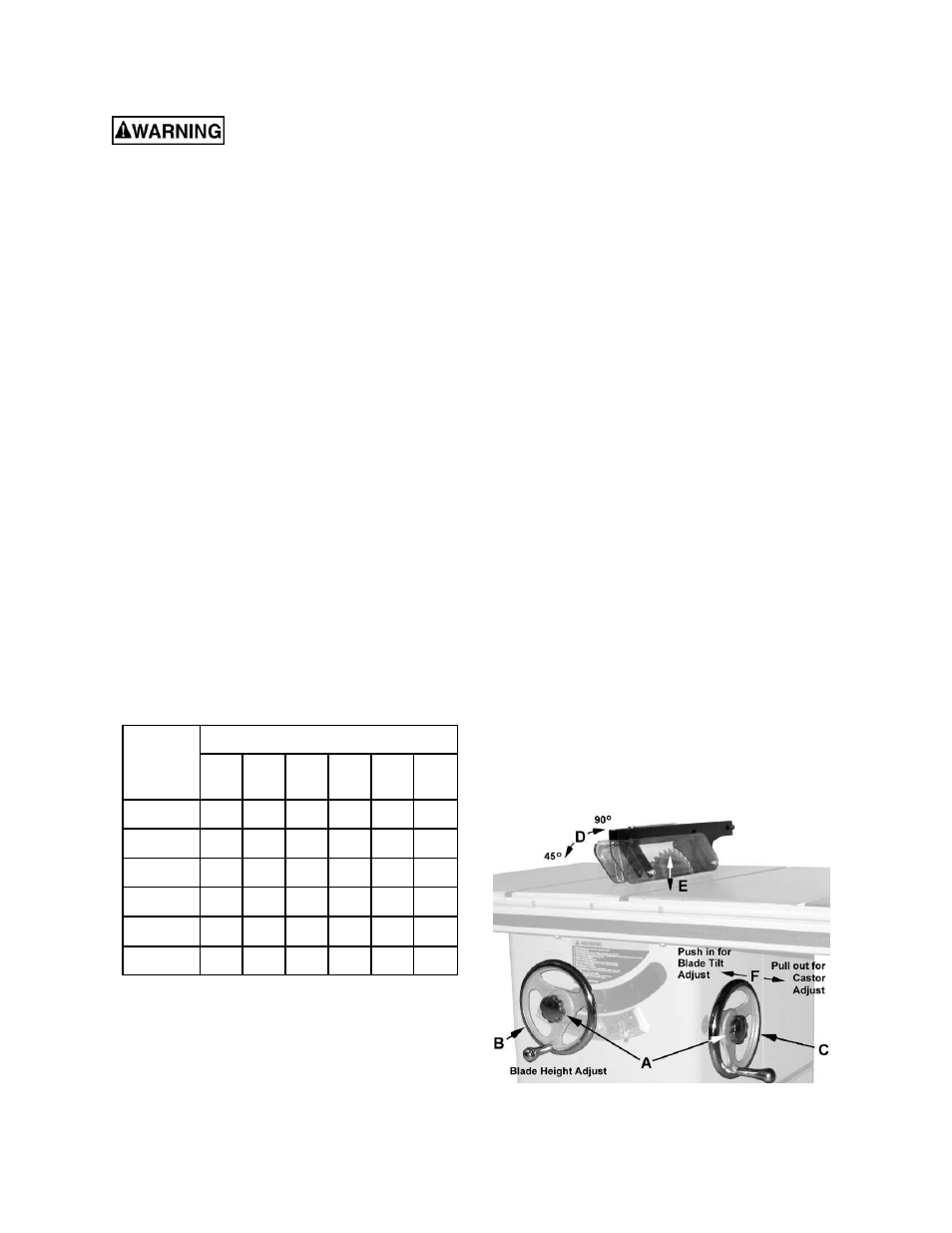

Handwheel Adjustments

Referring to Figure 11:

The front handwheel (B) controls the raising and

lowering of the blade (blade height).

The side handwheel (C) controls the blade tilt and

castors. The blade can be adjusted for a tilt

between 90º (vertical or a setting of 0º on the scale)

and 45º left tilt (D). The Model 2000 also has a

retractable castor system that can be extended to

permit the table saw to be rolled from one location

to another.

Blade height

1. Loosen

the

lock knob (A) on the blade height

adjust handwheel.

2. Turn

the

handwheel (B) clockwise to raise and

counterclockwise to lower the blade.

3. Tighten

the

lock knob (A).

Blade tilt adjustment

1. Loosen the lock knob (A) on the side

handwheel (C).

2. Push

the

handwheel

in (F).

3. Turn the handwheel (C) counterclockwise to

adjust the saw blade down to 45º left tilt (D).

Turn clockwise to adjust the saw blade to

maximum of 90º (D).

4. After selecting the position, tighten the lock

knob (A).

Figure 11