Pitco Frialator SE18 User Manual

All models available in 17kw or 22kw

Pitco Frialator, Inc., P.O. Box 501, Concord, NH 03302-0501

•

1

509 Route 3A, Bow NH 03304, USA

Phone (603) 225-6684 • FAX (603) 225-8472 • www.pitco.com

APPROVALS

UL Certified

CUL Certified

NSF Listed

CE Certified

Patent Pending

Project

Item No.

Quantity

Model SE14, SE14T & SE18 Solstice Electric Series Fryers

Solstice Electric Series Fryers

Model SE14, SE14T & SE18

All Models Available in 17kW or 22kW

L10-146 Rev

3 (02/07)

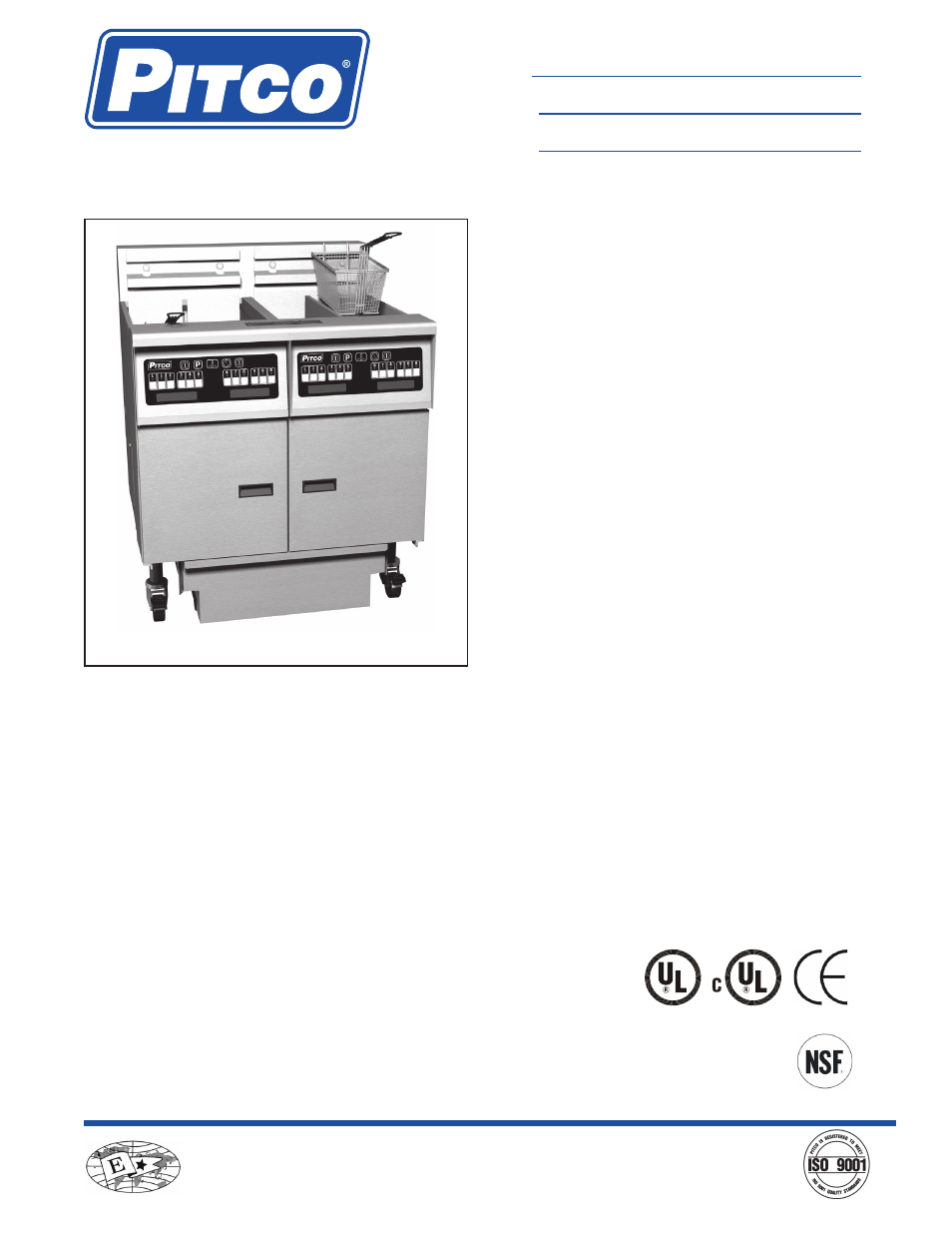

(Model shown is SE14/SE14T with optional Intellifry

Computers, casters and filtration system)

STANDARD ACCESSORIES

Solid State Control

Drain Valve Interlock

Baskets (Twin Size)

Tank racks

Lift off basket hangers

Clean out rod

9" adjustable legs

Fryer cleaning brush

Stainless steel tank,

front, door and sides.

AVAILABLE OPTIONS & ACCESSORIES

Digital controller

Intellifry computer

Solid state back-up control*

Filter drawer system (for 2 or more fryers)

Filter system heat tape (for use with solid shortening)

9" adjustable casters

Basket lifts**

Stainless steel back

Stainless steel tank covers

Bread and Batter cabinet

Flush hose

Filter powder

Filter paper

* Solid state control equipped with melt cycle and boil-out, and can

beused as back-up in combination with the Intellifry or Digital

controls.

** Basket lifts to be used in combination with Intellifry or Digital control.

STANDARD SPECIFICATIONS

CONSTRUCTION

Build a Solstice Electric fryer system in any combination

of full tank and twin tank fryers with "filter drawer"

filtration system. Combinations without filtration, or single

fryers also available.

Welded tank with an extra smooth peened finish ensures

easy cleaning.

Immersion type; sealed construction heating elements

with high temperature alloy stainless steel sheath.

Solstice Electric fryers are designed with a fixed heating

element to eliminate oil migration through pivot

components. This design creates a safer working

environment by keeping the hot elements in the tank

where they belong.

When used with a filtration system, fryers are available in

combinations of two or more units.

Stainless steel front, door, side panels, and splashback.

Heavy duty 3/16” (.48 cm) door hinge.

CONTROLS

Solid State controller maintains the fryer temperature

between 250°F (122°C) and 380°F (193°C). Solid State

controller has built-in melt cycle and boil-out capability.

Temperature limit switch safely shuts off the fryer if the

oil temperature exceeds the upper limit.

Drain valve interlock switch shuts disables the fryer if the

drain is opened preventing accidental fires. The

hermetically sealed proximity switch has no moving parts

to get contaminated with grease.

OPTIONAL FILTER SYSTEM

(Available on 2 or more units)

Filter drawer glides on self aligning roller-less guides

1-1/4” NPT drain valve for quick draining on both full and

twin tanks.

Easy to remove filter unit for fast cleaning and paper

replacement.

Filter piping integrated into the fryer for no-hassle

filtering.

Extra large 3” drain manifold to prevent clogging.