Paladin Tools LAF2301 User Manual

Page 12

10

BACKHOE SERVICE (continued)

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY INSTRUCTIONS (pages 2-5

of this manual) BEFORE BEGINNING ANY BACKHOE SERVICE

x

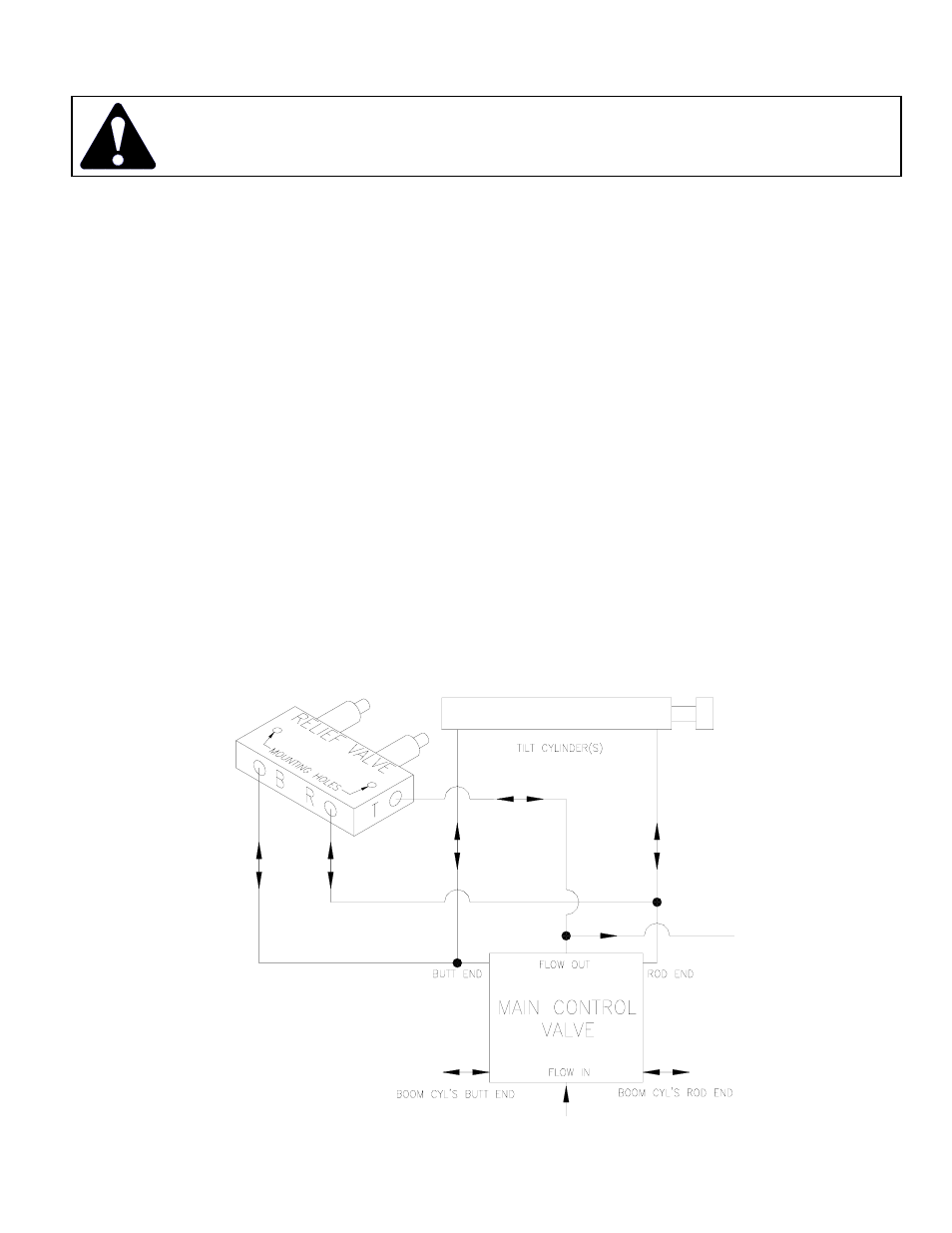

Locate a convenient place to “tee” into the loader’s tilt circuit lines after they have passed through any self-

leveling devices or any other devices which may be present on these lines (refer to your loader’s service manual).

Locate a convenient area to “tee” into a return to tank line. Once these areas are located, find an area in close

proximity for mounting the relief valve. The valve can be mounted in any position. Every effort should be made to

ensure accessibility to the valve, its cartridges, fittings and any lines that will be added. Careful consideration

should also be made as to the type and size of the fittings and hoses that will be required before dismantling any

hydraulic circuitry. Keep any added fittings, hoses, or the valve a safe distance from all moving parts of the

machine. 3/8” pipe fittings, ½” SAE o-ring or JIC fittings and 3/8” hydraulic hoses are all adequate for the amount

of flow required. The valve’s ports accept 3/8” NPT pipe fittings or SAE #8 o-ring, depending on the model of

valve. Be sure to differentiate between the two styles before proceeding.

NOTICE

If using NPT pipe fittings (anywhere on the loader’s circuit), it is recommended that you use a eflon

based thread sealant. Do NOT use eflon tape as it may enter the loader hydraulic circuit and cause

relief poppets to stick open.

x

Install the line from the butt end of the loader’s tilt cylinders into port “B” on the valve. Install the line from the rod

end of the cylinder into port “R” on the valve and the return to tank line into port “T”. Make sure all fittings and

hoses are tightened securely and no hoses are stretched, severely bent, or kinked before mounting the valve.

x

Using the valve as a template, mark the location of two 9/32” holes. Remove the three lines connected to the

valve and seal the line ends to keep out contaminants. Drill the previously located holes.

IMPORTANT

When drilling holes, be sure that you are not drilling into a reservoir or any other sealed

compartment. Also be careful not to damage any hydraulic lines, fittings, pumps, valves,

manifolds, electric components, batteries, steering linkages, safety devices, etc.

x

Reassemble the three lines onto the valve and install mounting bolts. Check all connections for proper fit and

tightness.

x

Replace all guards, shields, and covers.

x

Replace estimated lost hydraulic fluid using your loader’s specifications.

x

Start loader; reposition the boom arms and dump cylinders according to the loader manufacturer’s

recommendations for checking fluid levels. Add fluid as needed.