Maintenance – Poulan Pro PP4300 User Manual

Page 19

19

MAINTENANCE

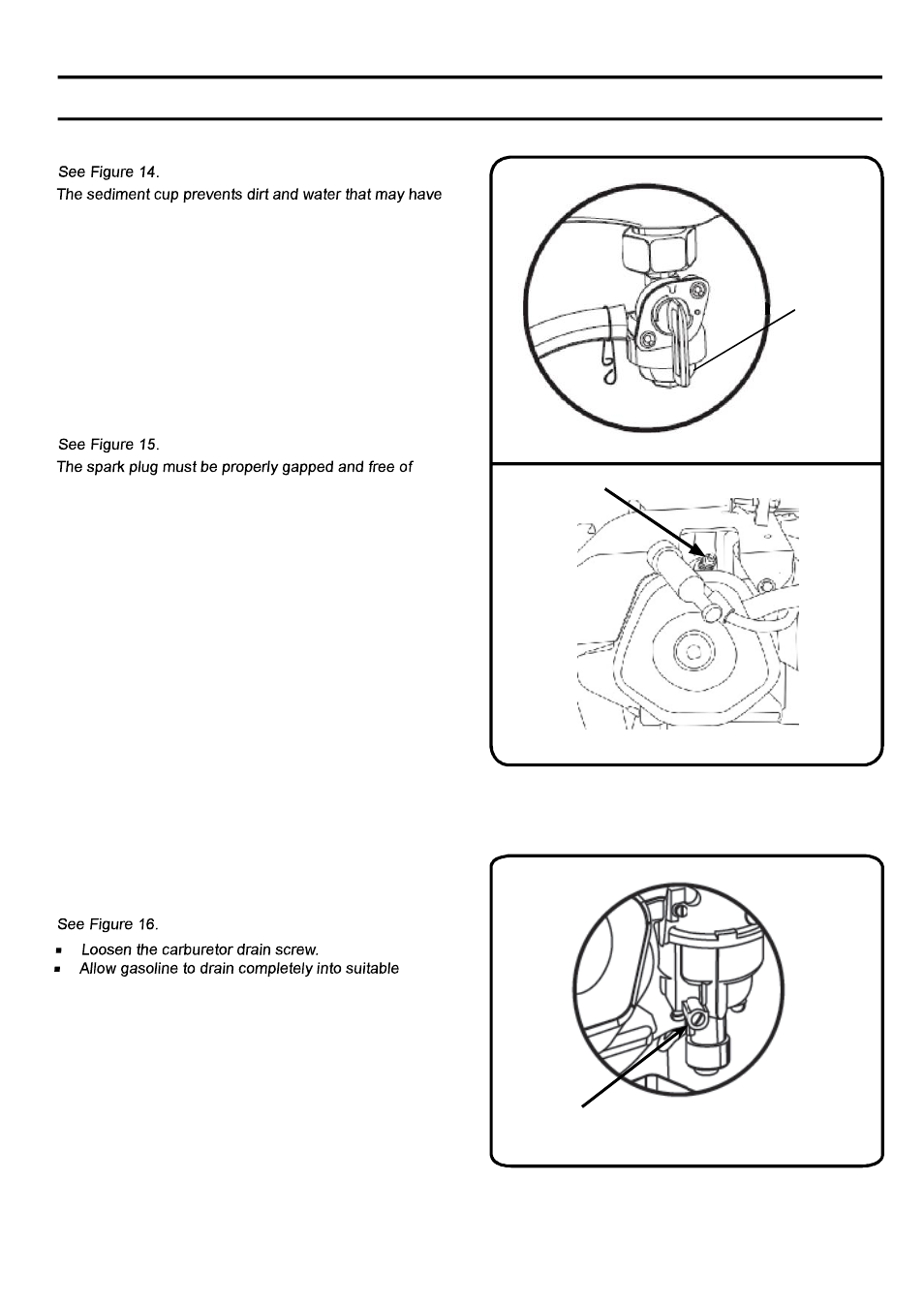

CLEANING FUEL SEDIMENT CUP

gotten into the fuel tank from entering the carburetor. If

the engine has not been run for a long time, the sediment

cup should be cleaned before use.

Turn the fuel valve to the off position.

Remove the sediment cup using a 10 mm wrench.

Remove the o-ring and filter.

Clean each of the parts in a high flash-point solvent.

Reinstall the filter, o-ring, and sediment cup. Tighten

■

■

■

■

■

with 10 mm wrench to secure.

Return the fuel valve to the ON position and check

■

for leaks.

SPARK PLUG MAINTENANCE

deposits in order to ensure proper engine operation.

To check the spark plug:

Remove the spark plug cap.

Clean any dirt from around the base of the spark

■

■

plug.

■

■

Remove the spark plug.

Inspect the spark plug for damage, and clean with

a wire brush before reinstalling. If the insulator

is cracked or chipped, the spark plug should be

replaced.

NOTE: If replacing, use the following recommended

spark plugs or equivalent: NGK,

.

Measure the plug gap with a feeler gauge. The

FT7C

■

correct gap is .028 - .031 in. Correct, if necessary, by

carefully bending the side electrode.

Seat spark plug in position; thread in by hand to

■

prevent cross-threading.

■

Tighten with spark plug wrench to compress washer.

If spark plug is new, use 1/2 turn to compress

washer appropriate amount. If reusing old spark

plug, use 1/8 to 1/4 turn for proper washer

compression.

Fig. 15

Fig. 14

SPARK PLUG

SEDIMENT

CUP

DRAINING CARBURETOR

container.

■

■

■

Retighten drain screw.

Turn the engine switch and fuel valve OFF.

TRANSPORTING

Make sure engine and exhaust system of unit is cool.

■

■

Keep the unit level to prevent fuel spillage.

Do not drop or strike the unit or place under heavy

objects.

Fig. 16

DRAIN SCREW