Powermatic HPS67 User Manual

Page 12

12

5. Unlock the nut (NOTE: Left hand threads –

loosen by turning clockwise).

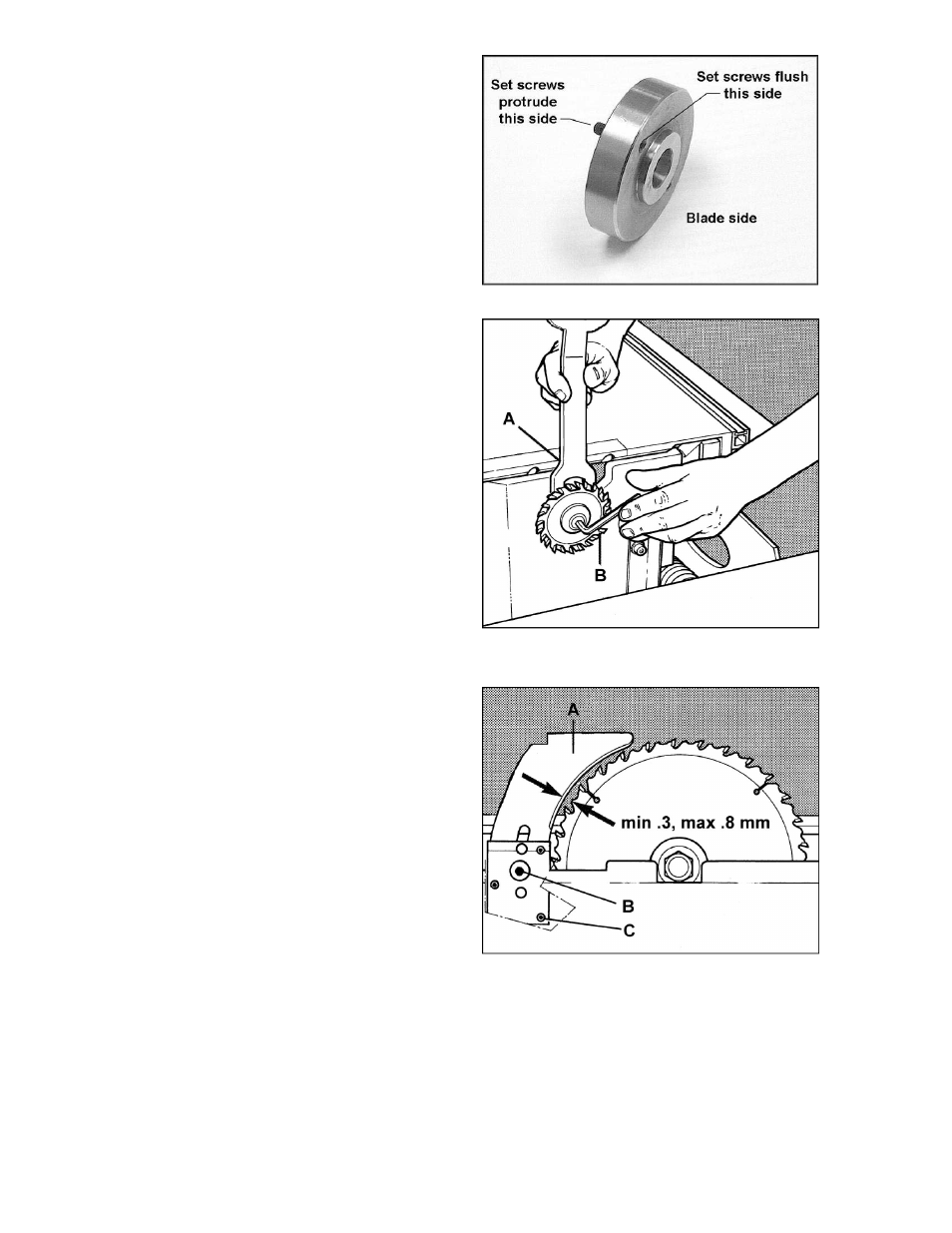

6. Make sure the set screws in the adaptor are

set flush on the blade side. (They should

protrude to the rear to engage the arbor for

positive drive). See Figure 16. Clean the

mating surfaces, install new blade, and

tighten arbor nut securely.

7. Remove locking pin (B, Figure 15) and close

blade cover.

SAFETY TIP: Tape a red rag on the locking pin

and drape it over the blade while pin is inserted.

This will remind you to remove the pin before

starting the saw!

Installing/Replacing Scoring Blade

1. Disconnect machine from power source.

2. Push sliding table all the way to the left and

open blade cover.

3. Tilt scoring blade all the way, and place

spanner (A, Figure 17) on the flat of the

arbor.

4. Loosen the bolt with the hex wrench (B,

Figure 17). (NOTE: Right hand threads-turn

counterclockwise to loosen).

5. Mount scoring blade and re-tighten bolt.

Close blade cover.

Riving Knife

The machine is equipped with a riving knife (A,

Figure 18) for use with saw blades up to 315mm

in diameter.

The purpose of the riving knife (or "splitter") is to

prevent the kerf from closing as it leaves the

cutting teeth, and thereby reduce the chance of

the kerf coming in contact with the up-running

teeth of the blade and causing binding or a

dangerous kickback. When the forward edge of

the workpiece reaches the riving knife, the knife

also helps guide the rest of the cut and will

prevent the up-running teeth from scoring the

workpiece.

The riving knife must be adjusted so that over its

entire length the gap between saw blade and

riving knife does not exceed 3 to 8mm.

The riving knife can be adjusted in both vertical

and horizontal directions. The highest point of

the riving knife should never exceed 3mm above

the highest placed saw blade tooth.

Use the central bolt (B, Figure 18) and the three

adjustment screws (C, Figure 18). After

adjustment, always lock the central bolt (B,

Figure 18).

Figure 16

Figure 17

Figure 18