Operation, Assembly specifications operation, Before each use – PYLE Audio PT502 User Manual

Page 5: Accessories required

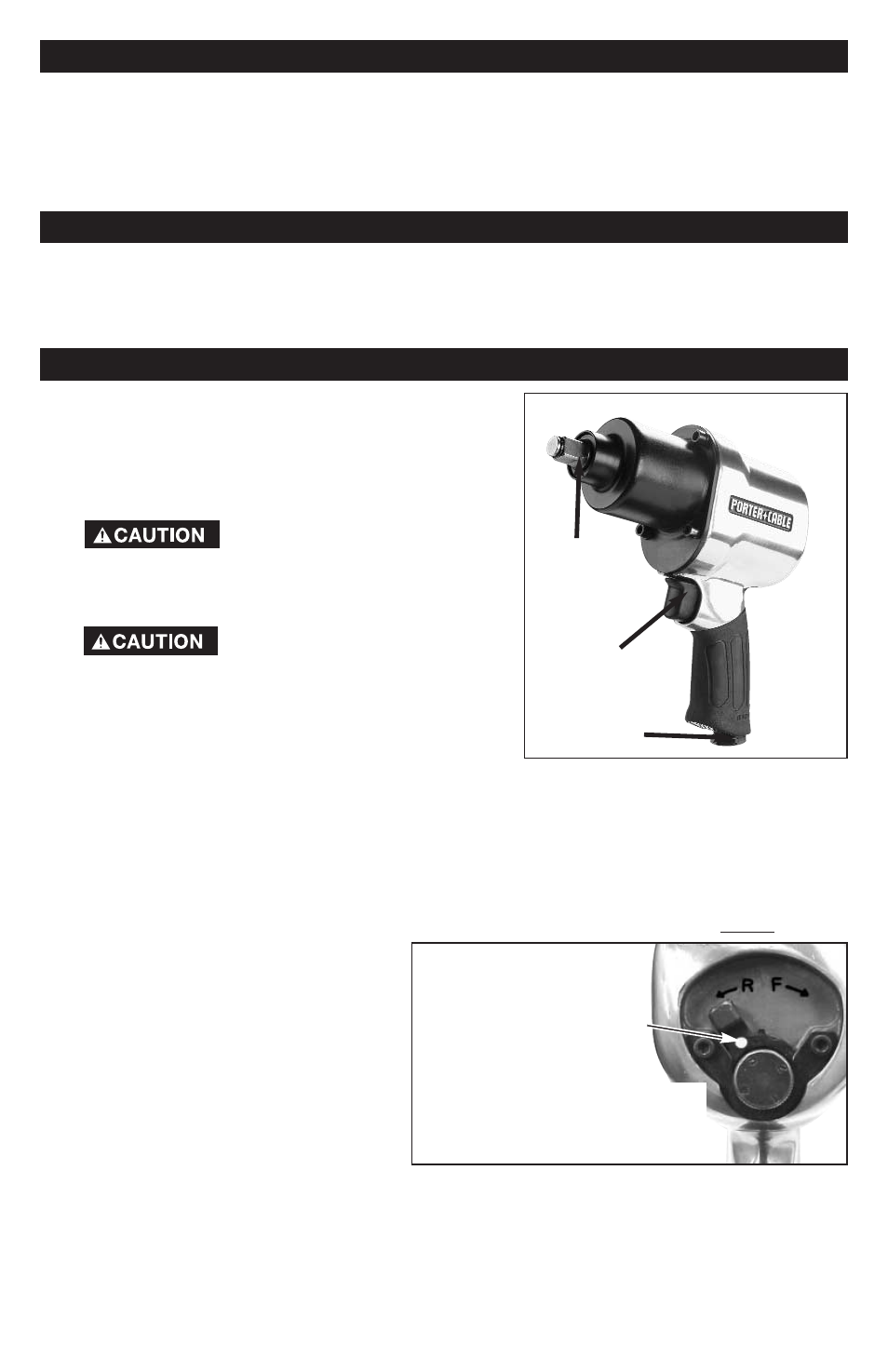

Operation

Before each use:

●

Drain water from air compressor tank and conden-

sation from air lines. See air compressor’s operators

manual.

Disconnect the tool from the air

supply before lubricating or

changing sockets.

●

Lubricate tool, see “Maintenance” section in this

manual.

Impact wrench sockets and

accessories must be used with

this tool. Do not use hand sockets and

accessories.

●

Select the required impact socket. This tool has a

1/2" square drive, use 1/2” deep sockets. Use 1/2”

extensions only when needed.

●

Connect tool to air hose of recommended size. NOTE: The use of a quick connect set makes

connecting easier.

IMPORTANT: The use of air filters and air line lubricators is

recommended.

To use:

●

Turn air compressor on and allow air tank to fill.

●

Set the air compressor’s regulator to 90 PSI. This tool operates at a maximum 90 PSI

pressure.

●

Set torque regulator, see chart, to set

the desired setting to avoid over

tightening.

IMPORTANT: These torque values can vary

depending on the size of the air compressor

and the cubic feet of air (SCFM) the air

compressor delivers.

●

Place tool in forward or reverse position.

Place in “F” position for forward or “R”

position for reverse.

●

Depress the trigger to operate tool.

●

Release trigger to stop tool.

●

Always disconnect air supply when changing sockets.

●

When job is complete, turn the air compressor off and store as described in the air

compressor operator manual.

5- ENG

D22724

ASSEMBLY

SPECIFICATIONS

OPERATION

Maximum Torque

500 ft./lbs

Blows Per Minute

1,000

Maximum Working Pressure

90 PSI

Air Inlet

1/4” NPT

Recommended Hose Size

3/8” I.D.

Air Consumption @ 90 PSI

4.2 SCFM

Accessories Required

IMPORTANT: Line pressure or hose inside diameter should be increased to compensate for

unusually long air hoses (over 25 feet). Minimum hose diameter should be 3/8” I.D. and fittings

should have 1/4” NPT thread.

#1 approximately 200-275 ft./lbs. Torque

#2 approximately 275-350 ft./lbs. Torque

#3 approximately 350-425 ft./lbs. Torque

#4 approximately 425-500 ft./lbs. Torque

Line desired torque # up with

indent

Air Inlet

Trigger

1/2”

Square

Drive