Pentair Slide Backwash Valve User Manual

Page 7

Page 7

Figure 10. Slide Valve Performance Curve -

(Slide Valve with DE Filter Data Shown)

0.0

2.3

4.6

6.9

9.2

11.5

0

50

100

25

75

125

Flow Rate, GPM

Feet

of

Hd,

Ft.

h

d.

0.0

1.0

2.0

3.0

4.0

5.0

Pressure

Loss,

PSI

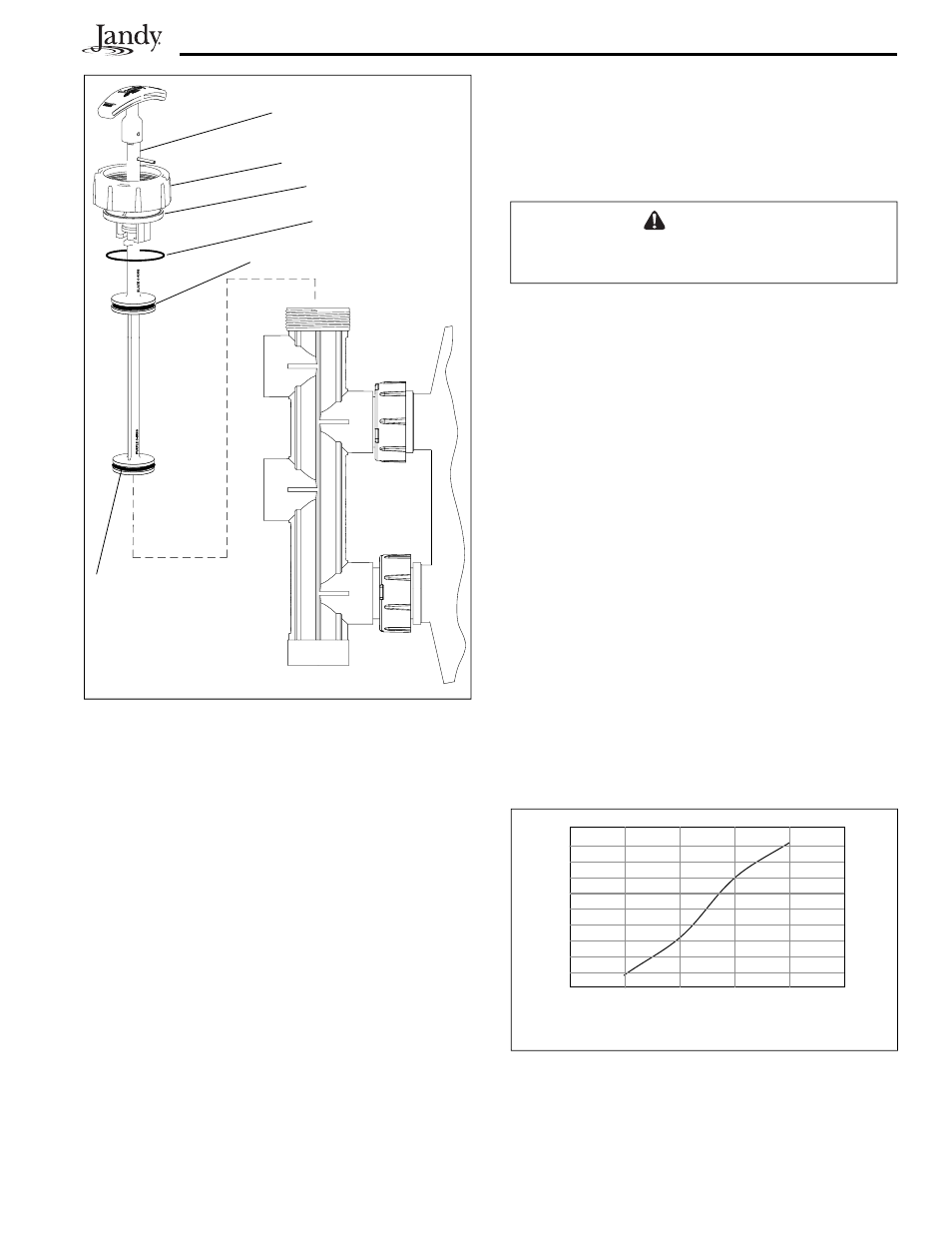

5. Inspect the shaft and the o-rings for wear, cuts,

cracks, and debris. If the o-rings show any sign of

wear or damage, replace with Jandy O-ring and

Roll Pin Replacement Kit (P/N R0442100).

NOTE The o-ring inspection includes the Lid o-ring.

Please be aware that the roll pins are different

lengths; the handle roll pin is 1" long and the

shaft roll pin is

13

/

16

" long.

6. Wash the shaft and o-rings with clean water and

dry with a lint-free cloth. Ensure that all debris is

removed.

7. Wash the lid surface of the valve (where the lid

o-ring is seated) and dry with a lint-free cloth.

Ensure that all debris is removed.

8. Lubricate o-rings with 100% silicone grease

lubricant, like Magic Lube

®

. Do not use any

lubricant containing petroleum products.

9. Place the shaft back into the Slide Valve and

tighten the lid union nut.

10. Return the Slide Valve handle to the normal

operating position (see Section 3).

11. Turn on system pump(s) and check for normal

water fl ow.

Section 6. Winterizing

Lid O-ring

Shaft O-ring, Top (Black)

Shaft O-ring, Bottom

(Purple)

Shaft Assembly

Figure 9. Remove Slide Valve Shaft Assembly

Lid Union Nut

Index Plate/Lid

CAUTION

If not properly winterized, damage to the Slide Valve

will occur, which will increase the potential of injury.

1. Turn off the system pump(s).

2. Release all pressure from the system at the main

fi lter.

3. Loosen the lid union nut (see Figure 8).

4. Grab the Slide Valve handle and pull the shaft

assembly out of the valve (see Figure 9).

5. Allow all water to drain out the valve.

6. When it is confi rmed that there is no water left in

the valve, place the shaft back into the Slide Valve

and tighten the lid union nut.

7. Position the Slide Valve in Backwash mode (see

Section 4).

(DE Filters) Ensure that the Slide Valve handle is

fully extended (handle pulled all the way up). See

Figure 7.

(Sand Filters) Ensure that the Slide Valve handle

is fully depressed (handle and piston pushed all

the way down). Turn the handle until the stainless

steel pin on the piston locks into the position

bracket.