Installation and tapping, Concessionaire dispensers, Connecting the regulator to the co – Perlick DC Series User Manual

Page 5: Cylinder, Adjusting the co, Gas flow, Leak test, Replacing co, Gas cylinder, Proper co

Form No. Z2060A

Rev. 12.05.03

5

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Installation and Tapping –

Concessionaire Dispensers

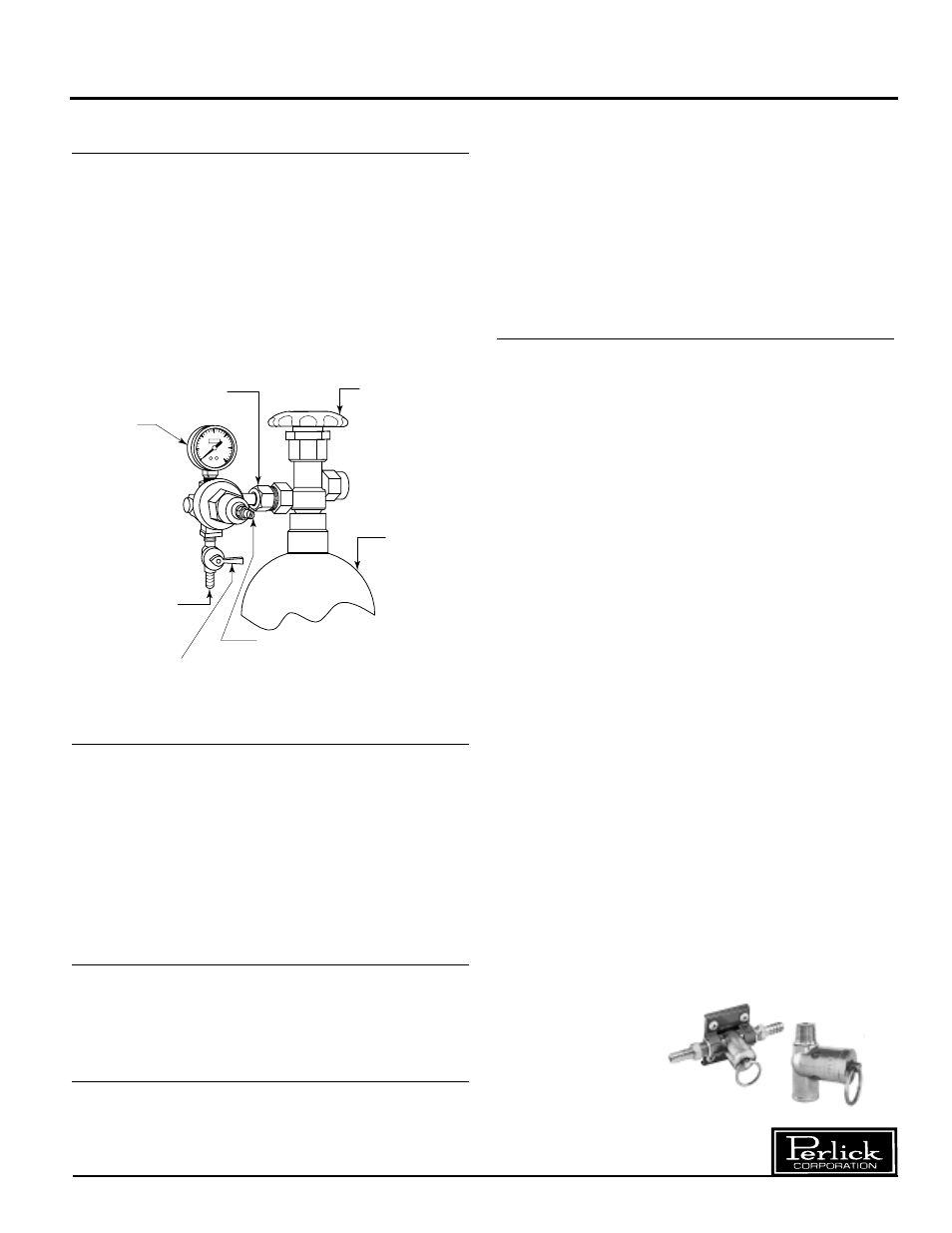

Connecting the Regulator to the

CO

2

Cylinder

■

Remove blue plug from regulator fitting.

(Note: Do not remove the carbonic washer).

■

Screw regulator onto gas cylinder valve. Tighten

with wrench until vertically straight. Be sure that

shut-off valve (black lever) on regulator is in

the OFF (horizontal) position.

■

Place a screw clamp over end of red air line

and push onto regulator tailpiece. Tighten clamp

with a screwdriver.

Adjusting the CO

2

Gas Flow

■

Turn regulator adjusting screw counterclockwise

until it turns freely.

■

Turn hand valve counterclockwise on CO

2

cylinder to the fully open position.

■

Turn regulator adjusting screw clockwise until

desired pressure is reached (approximately

12-15 lbs.). Tighten stop nut on adjusting screw.

■

Open shut-off valve on bottom of regulator.

CO

2

Leak Test

Dilute a small amount of liquid dishwashing soap

and rub the soapy mixture around each connection.

If bubbles appear, tighten connection.

Replacing CO

2

Gas Cylinder

■

Turn CO

2

hand valve clockwise until seated and

close shut-off valve on regulator.

■

Unscrew regulator from cylinder fitting.

■

Replace carbonic washer (Part No. 157F2P),

if needed and reattach regulator to filled

cylinder.

■

Turn CO

2

hand valve counterclockwise until

fully open. Turn regulator shut-off valve to

open position.

■

Adjust CO

2

gas flow as required, turning

clock wise for higher pressure.

Proper CO

2

Handling

ALWAYS

...

■

Connect a regulator (reducing valve) to

CO

2

cylinder.

■

Secure cylinder in upright position whether in

storage or in use.

■

Keep cylinder away from heat. Rupture disc

vents at 122° F. maximum.

■

Ventilate room after high pressure gas leakage.

■

Check the last DOT test date on cylinder neck

before filling. If more than five years old, the

cylinder must be retested to DOT specifications.

■

Be sure CO

2

cylinder outlet fitting is free of dust

or dirt before attaching regulator.

■

Store CO

2

cylinder and regulator assembly

upright.

■

Allow only properly trained and experienced

personnel to handle high pressure gas.

NEVER

...

■

Connect cylinder directly to a keg without a

regulator (reducing valve).

■

Drop or throw regulator or CO

2

cylinder.

■

Transport CO

2

cylinder in a closed vehicle.

■

Apply oil to a regulator.

■

Shut off CO

2

cylinder when not in use. You will

not save gas by doing so!

■

Allow untrained, inexperienced personnel to

handle high pressure gas.

Failure to heed this warning could result in

personal injury or death.

CO2

PRESSURE

GAUGE

CO2

GAS

DRUM

REGULATOR

FITTING

REGULATOR

ADJUSTING

SCREW

FITTING FOR

RED AIR HOSE

SHUT-OFF VALVE

(BLACK LEVER IN

CLOSED POSITION)

HAND

VALVE

PERLICK

PSI

10

50

0

60

20

40

30

WARNING/SAFETY INSTRUCTIONS

Beverage systems pressur-

ized with carbon dioxide or

nitrogen must be equipped

with two safety relief

valves; one at the cylinder

regulator and the other in

the gas line upstream on

the product tanks.