Warning – Poulan 545117551 User Manual

Page 18

18

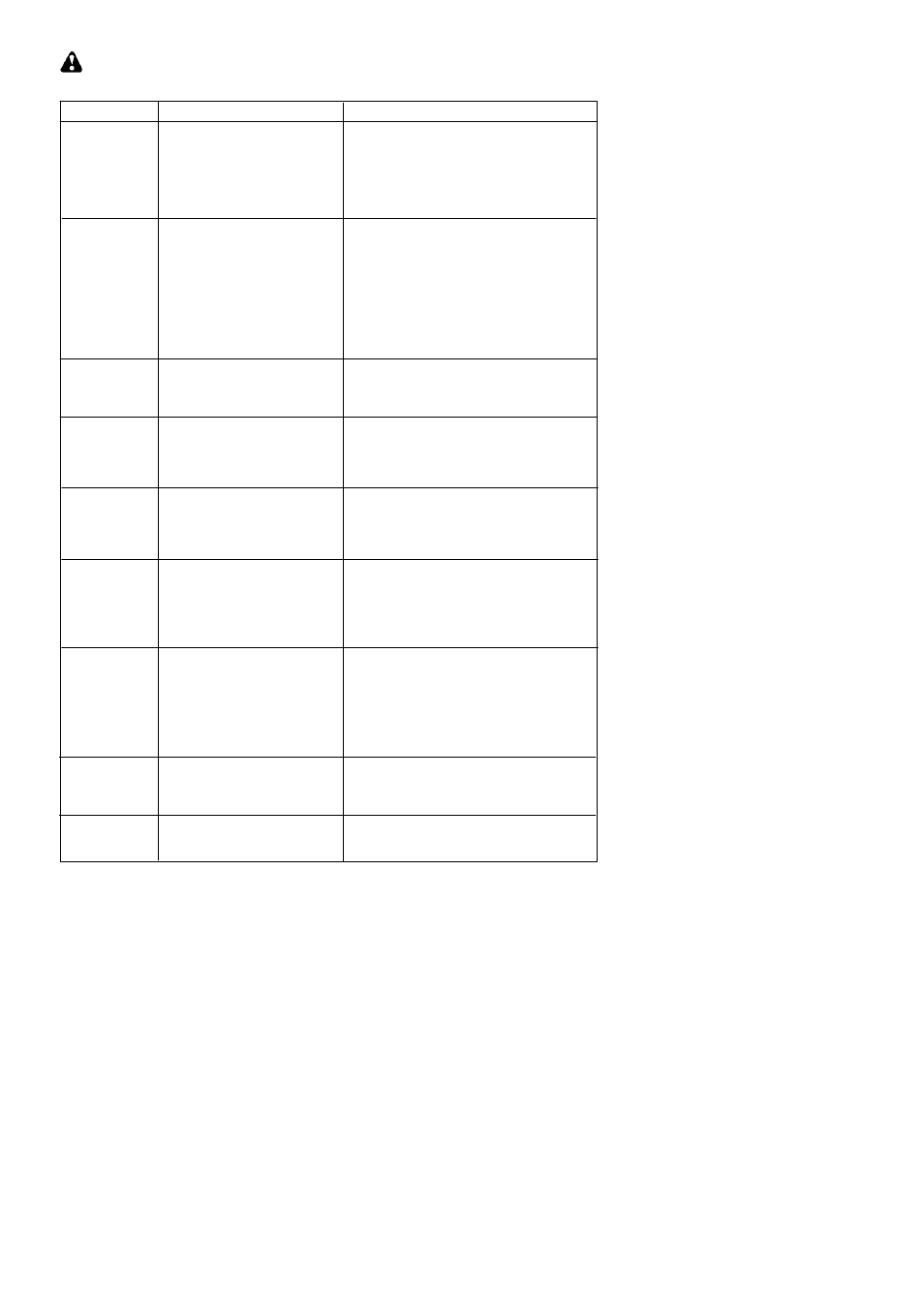

TROUBLE

CAUSE

REMEDY

Chain does

not move

when trigger

switch is

engaged.

1. Chain tension incorrect.

2. Guide bar rails pinched.

3. Trigger switch failure.

4. Circuit breaker tripped/

fuse failure.

1. See “Check Chain Tension” in

Maintenance section.

2. Repair or replace.

3. Contact an authorized service

dealer.

4. Reset circuit breaker or replace fuse.

Chain clatters

or cuts

roughly.

1. Chain tension incorrect.

2. Cutters damaged.

3. Chain worn.

4. Cutters dull, improperly

sharpened, or depth

gauges too high.

5. Sprocket worn.

1. See “Check Chain Tension” in

Maintenance Section.

2. Contact an authorized service

dealer.

3. Resharpen or replace chain.

4. See “Chain Sharpening” in

Service and Adjustments section.

5. Contact an authorized service

dealer.

1. Chain cutter tops not

filed flat.

2. Guide bar burred or

bent; rails uneven.

Chain stops

during cut.

1. See “Chain Sharpening” in

Service and Adjustments section.

2. Repair or replace guide bar.

WARNING:

Always stop unit and disconnect from the power source before per-

forming all of the recommended remedies below except remedies that require unit to be

operating.

TROUBLESHOOTING TABLE

Oil inadequate

for bar and

chain lubrica-

tion.

1. Oil tank empty.

2. Oil outlet clogged.

3. Guide bar oil hole

blocked.

1. Fill oil tank.

2. Contact an authorized service

dealer.

3. Remove bar and clean.

Chain cuts at

an angle.

1. Cutters damaged on

one side.

2. Chain dull on one side.

3. Guide bar bent or worn.

1. See “Chain Sharpening” in

Service and Adjustments section.

2. See “Chain Sharpening” in

Service and Adjustments section.

3. Replace guide bar.

Trimmer head

stops under a

load or does

not turn when

switch is

pressed.

1. Crowding trimmer line

against material being

cut.

2. Electrical failure.

3. Thrown circuit breaker.

4. Debris stopping head.

1. Allow tip of line to do the cutting.

2. Contact your authorized service dealer.

3. Check Breaker Box.

4. Remove debris.

Line does not

advance or

breaks while

cutting.

1. Line improperly routed

in head.

2. Line improperly

wound into spool.

3. Incorrect line size

4. Not enough line

outside of head.

5. Dirt buildup on unit.

1. Check line routing.

2. Rewind line tightly and evenly.

3. Use only 0.080 inch (2 mm) dia. line.

4. Remove cover and pull 4 inches

(10 cm) of line out of head.

5. Clean unit.

Line welds

onto spool.

1. Use only 0.080 inch (2 mm) dia. line.

2. Replace with correct spool.

3. Cut with tip of line fully extended.

1. Line size is incorrect.

2. Incorrect spool.

3. Line is being crowded

against material being cut.

Line releases

continuously.

1. Line improperly

routed in head.

2. Spool damaged.

1. Check line routing.

2. Replace spool.