Assembly, Air supply connection, Dust collection – Powermatic WB-43 User Manual

Page 9

9

Assembly

The sander should be placed on a level, sturdy

floor, preferably concrete, with plenty of space

surrounding it for on- and off-loading of stock,

and general maintenance work.

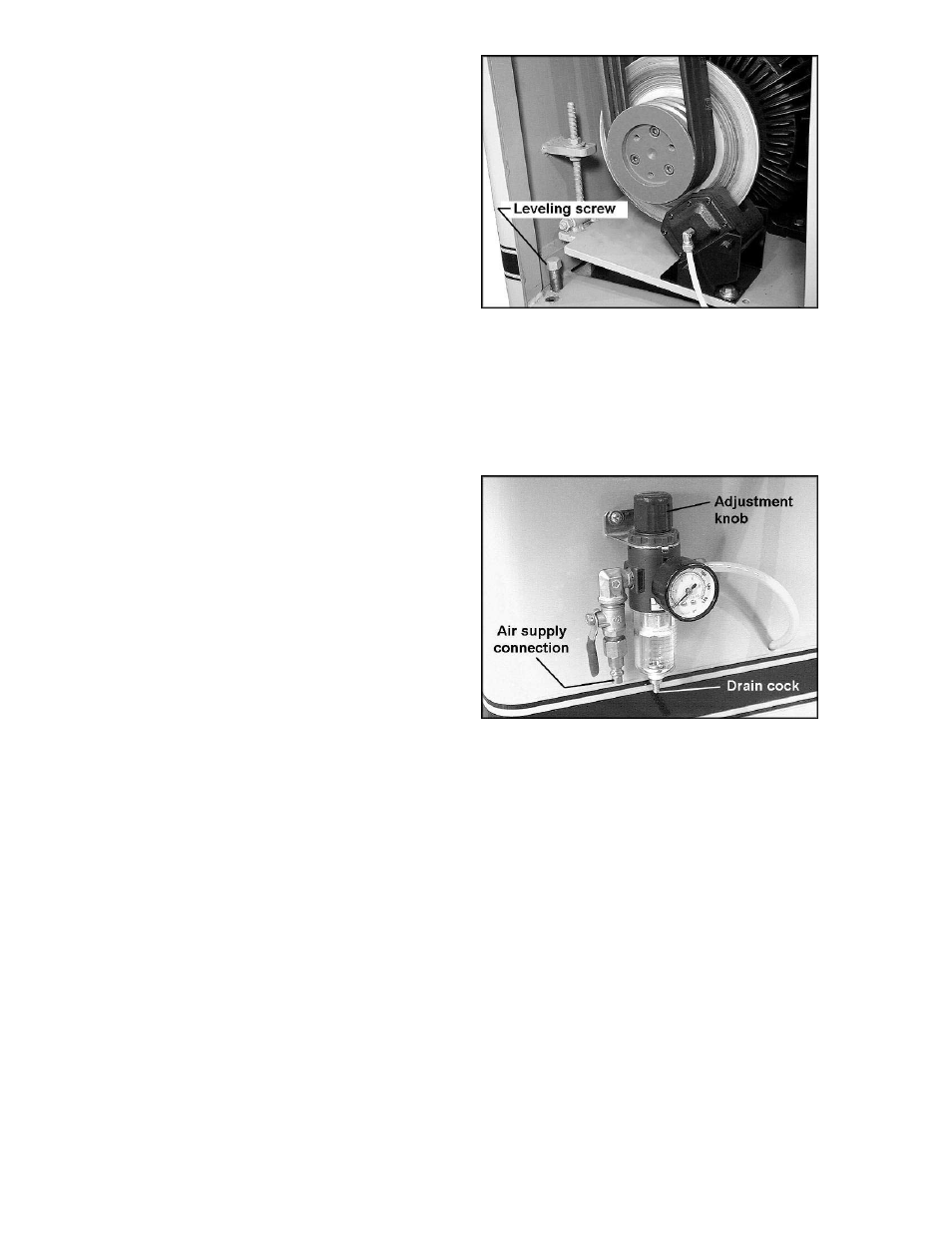

Open the two lower side panels and use the

leveling screws inside the cabinet (Figure 1) to

level the sander. The machine can also be

secured to the floor with high quality lag screws

(not provided) through the four mounting holes

inside the cabinet.

Remove the protective coating from exposed

metal surfaces with a soft cloth moistened with

kerosene or a good commercial solvent. Do not

use acetone, gasoline or lacquer thinner, as

these have a low flash point and can be a fire

hazard, as well as damage the paint finish. Do

not get solvents on rubber or plastic areas of the

machine.

Air Supply Connection

The sander must be connected to an air supply

unit. The recommended working pressure is 75

to 80 PSI.

The air connection is on the Filter/Regulator unit

located at the back of the sander (Figure 2).

Attach the incoming air supply to the connector

with a flexible hose.

The working pressure can be adjusted with the

pressure regulator. Lift up on the adjustment

knob and rotate it clockwise to increase air

pressure, counterclockwise to decrease air

pressure. When the desired pressure is shown

on the pressure gauge, push down the

adjustment knob to lock the setting.

Dust Collection

Connect a dust collection system (not provided)

to the dust ports atop the sander cabinet with 5”

flexible hose and hose clamps. Make sure your

dust collector has sufficient capacity for this

machine.

Always turn on the dust collector prior to

operating the sander.

Figure 1

Figure 2