Powermatic 64A User Manual

Page 12

12

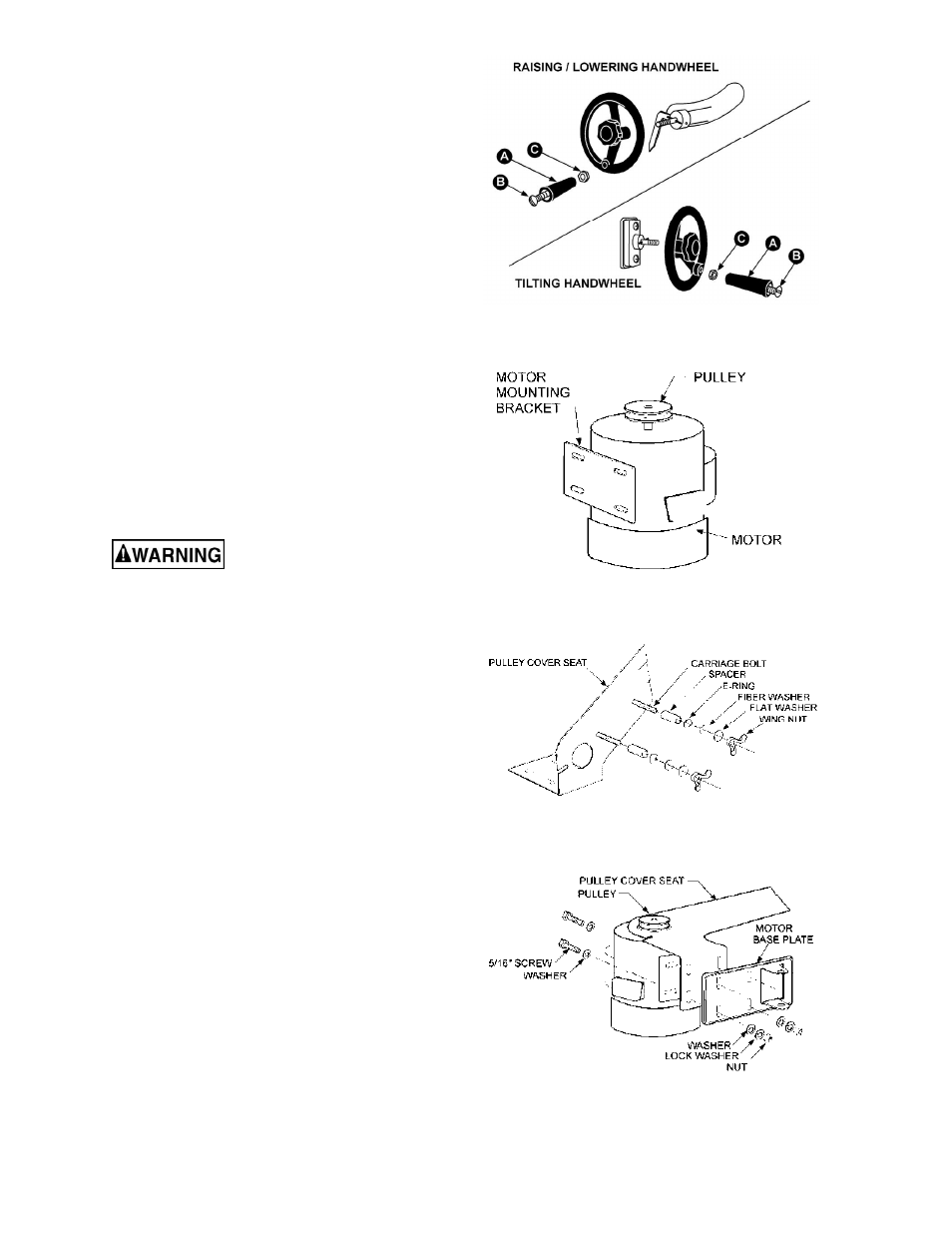

Handwheels and Lock Knobs

1. Attach handwheel knob (A) by inserting

screw (B) through hollow knob and into the

3/8" lock nut (C). See Figure 10. Lightly

screw assembly into handwheel.

2. Tighten the nut (C) to the handwheel just

enough so that there is adequate looseness

in the knob (A) to allow free rotation.

3. Attach the elevating and tilting handwheels

with lock knobs to the elevating and tilting

screws on the machine, as shown in Figure

10. Make sure the slot in both handwheels

engages with the roll pins in the elevating

and tilting screws.

Mounting the Motor

Make sure motor is

disconnected from power source while

assembling the saw.

1. Carefully set motor on its end with the pulley

at the top, as shown in Figure 11.

2. Install two 5/16-18 x 1-3/4 carriage bolts

through the holes in the pulley cover seat.

See Figure 12. Place a spacer over the bolt

shafts and temporarily install two 5/16 fiber

washers, two 5/16 wing nuts, and two E-

rings as shown.

3. Lay the pulley cover seat on the motor as

shown in figure 13.

4. Install motor base plate with four 5/16-18 x 1

hex head screws, four 5/16 flat washers,

four 5/16 lock washers, and four 5/16 nuts,

with the screw heads on the motor side, as

shown in Figure 13. Slightly tighten two of

the nuts to temporarily secure components.

5. Assemble the motor base plate to the cast

motor bracket as shown in Figure 14. Slip

pin through and secure with the hex head

set screw.

IMPORTANT: Before mounting the motor

assembly to the saw, turn the trunnion

handwheel so that the saw blade is in the 90

degree vertical position (or the saw's pointer

is on the zero mark).

Figure 10

Figure 11

Figure 12

Figure 13