Operation – Lincoln Electric INVERTEC V350-PRO IM679-A User Manual

Page 18

B-7

OPERATION

B-7

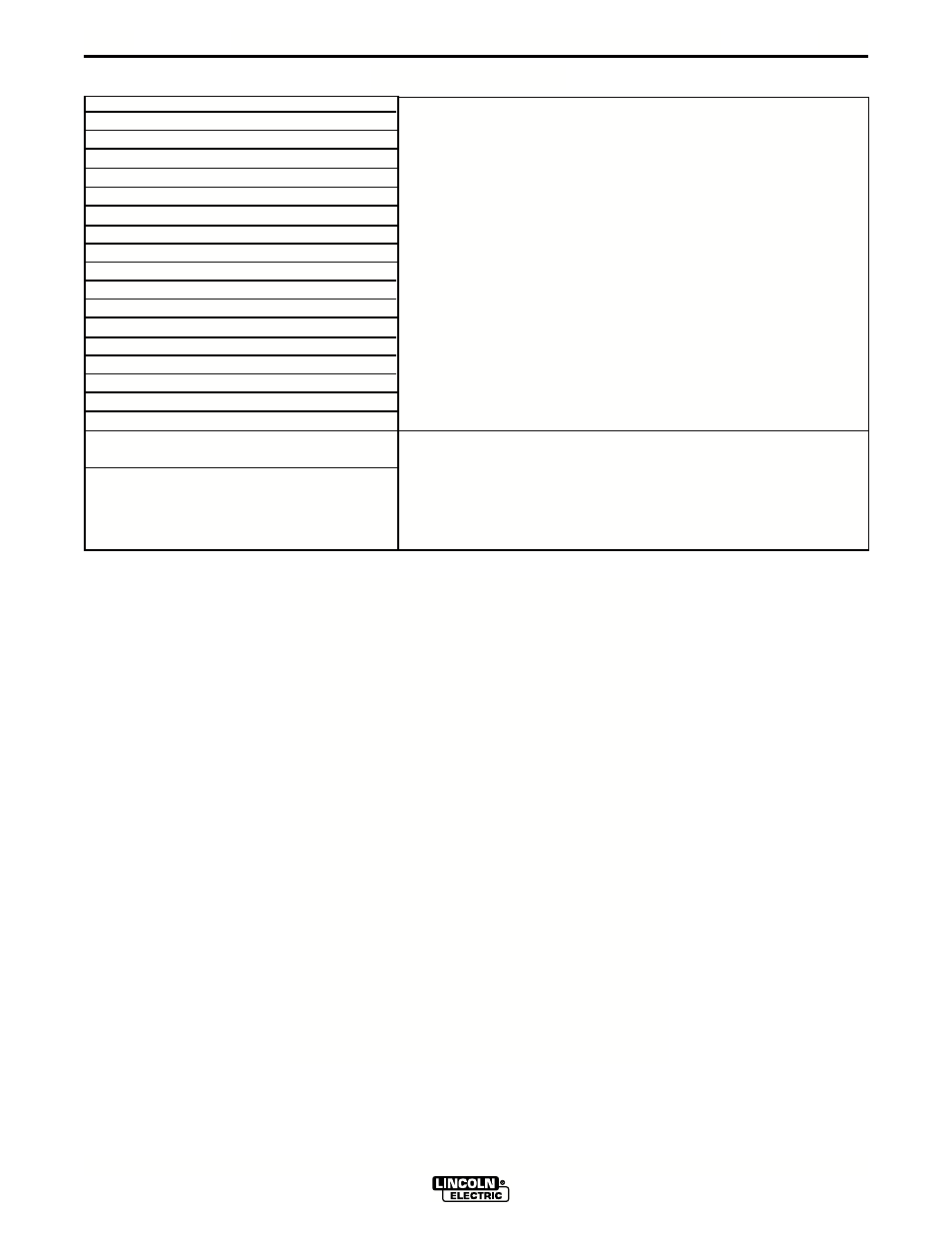

PULSE PROGRAMS:

V350-PRO

.030 Steel

65 - 1200

.035 Steel

55 - 800

.045 Steel

50 - 700

.052 Steel

75 - 550

.045 Metal Core

50 - 650

.052 Metal Core

50 - 500

.030 Stainless Ar Blends

85 - 770

.030 Stainless He Ar CO2

110 - 770

.035 Stainless Ar Blends

65 - 770

.035 Stainless He Ar CO2

75 - 770

.045 Stainless Ar Blends

50 - 600

.045 Stainless He Ar CO2

50 - 600

.035 Aluminum 4043

100 - 700

.035 Aluminum 5356

115 - 740

3/64 Aluminum 4043

80 - 550

3/64 Aluminum 5356

85 - 700

1/16 Aluminum 4043

75 - 325

1/16 Aluminum 5356

75 - 450

.035 Nickel Alloys

80 - 700

.045 Nickel Alloys

75 - 550

The V350 non synergic pulse programs allow independent control

of the wire feed speed and the arc length. The V350 Output Control

Knob adjusts the arc length similar to other processes. When oper-

ating in a pulse mode, the V350 displays a reference number as

the relative arc length. (Range given in center column.) Setting this

reference number to the actual wire feed speed of the feeder will

product close to the right arc length. The V350's output knob can

then be adjusted to dial in the correct arc length.

The Arc Control knob will fine tune the arc length to obtain the

desired results.

The Nickel Alloy pulse programs are non adaptive. The operator

sets the output control knob to deliver the correct arc length at

desired wire feed speed and stick out. While welding, the operator

manipulates the stick out to maintain the correct arc length. This

method of operation produces very stable arc performance consid-

ering the nature of nickel alloys.

LN-10/DH-10 Wire Feeder Compatibility Note:

The LN-10 and DH-10 feeders can be used to pulse

weld and in the power mode with the panel. The dis-

plays on the LN-10 & DH-10 do not show the wire

feed speed or power.

8. HOT START and ARC CONTROL

features

have different functions depending on the welding

Mode that is active. Each feature is described under

the welding mode heading. (See Item 7 or 7.A for

specified Mode Operations) (See Figure 1.A or

2.A)