Lochinvar EB-EWU-02 User Manual

Page 6

f.

Carefully reinstall combustion chamber door,

jacket panels, dividers, burners, manifolds wires and

hoses. Use new gasket material for proper air seal.

g.

Reassemble and test for gas leaks.

h.

Cycle appliance and check for proper operation.

An appliance installed in a dust or dirt contaminated

atmosphere will require cleaning of the burners on a 3 to 6

month schedule or more often, based on severity of

contamination. Contaminants can be drawn in with the

combustion air. Non-combustible particulate matter such

as dust, dirt, concrete dust or dry wall dust can block burner

ports and cause non-warrantable failure Use extreme care

when operating an appliance for temporary heat during

new construction. The burners and fan will probably

require a thorough cleaning before the appliance is placed

in service.

6. Combustion Air Fan: The combustion air fan should be

checked every 6 months. Clean as required when

installed in a dust or dirt contaminated location.

7. Water Circulating Pump: Inspect pump every 6 months

and oil as necessary. Use SAE 30 non-detergent oil or

lubricant specified by pump manufacturer.

8. Keep appliance area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

9. Check frequently to be sure the flow of combustion and

ventilation air to the boiler is not obstructed.

Operating Temperature Control

Locating Temperature Control

Remove the control panel door on the front of the appliance

in order to locate and access the temperature control.

Temperature Control Settings

There are three setting knobs on the temperature control

unless your appliance is specified as a boiler only with an

outdoor air reset option. If your appliance is a boiler only

with an outdoor air reset option, there are additional

controls for this option. They are explained under Outdoor

Air Reset Option, page 7.

The three setting knobs on the temperature control are for

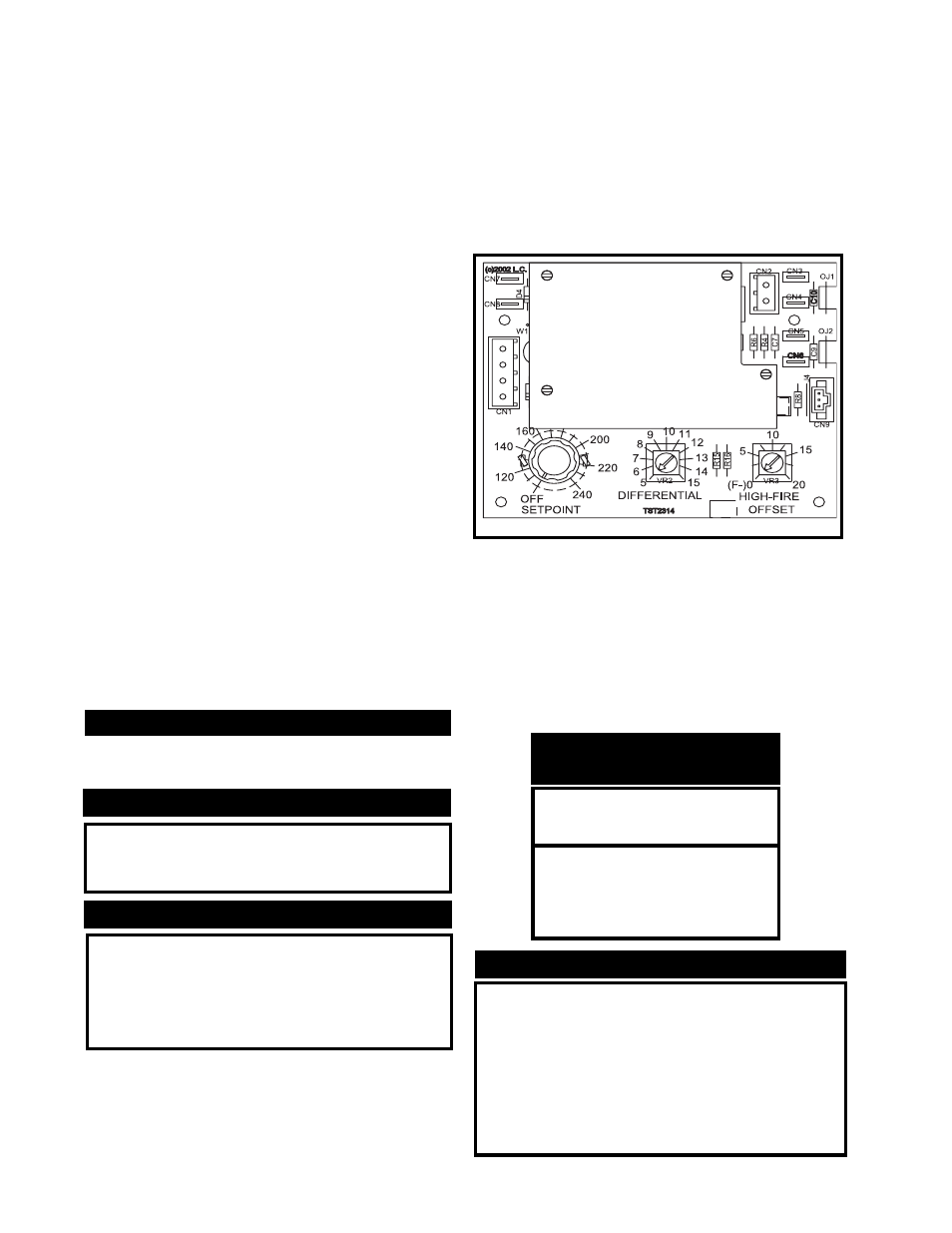

Set point, Differential, and High-Fire Offset (see Figure 5).

FIG. 5 Temperature Control

Maximum Set Point Determination

The maximum set point for the control is factory set.

Boilers can be set to 240°F max., water heaters are set to

190°F max., and specialty state and local codes to 200°F.

These maximum set points are established by cutting the

OJ1 and OJ2 jumpers located on the right side of the

temperature controller. The maximum set point is

determined as shown below in TABLE-B.

6

TEMPERATURE ADJUSTMENT

The temperature controller is pre-set at the factory

with test settings. You may need to adjust the

settings to meet your specific needs.

NOTE:

Return water temperatures must not be less than

140°F. If lower return water temperatures are

required, follow the instructions in the Low

Temperature Bypass Requirements or Three-Way

Valves section(s) in the Installation and Service

Manual.

ƽ

ƽ WARNING

Max.

OJ1

OJ2

Set Point

Connected

Connected

240°F

Cut

Connected

190°F

Connected

Cut

200°F

Cut

Cut

160°F

TABLE B

Maximum Set point Determination

Anytime that OJ1 is the only jumper cut, a new

overlay is required under the Set Point knob on the

temperature controller because the scale has changed

to a maximum of 190°F.

Anytime the OJ2 jumper is cut (with or without OJ1),

a new overlay is required under the Set Point knob on

the temperature controller because the scale has

changed to a maximum of 200°F.

NOTE: