Sidewall direct venting, Model air vent centerline width, Installation & operation manual – Lochinvar Wall Mount Boiler WH 55-399 User Manual

Page 24: Prepare wall penetrations

4

Sidewall direct venting

24

Installation & Operation Manual

VENT PIPING

GALVANIZED

THIMBLE

VENT CAP

AIR PIPING

WALL PLATE

VENT PLATE

VENT

AIR

CENTERLINE WIDTH

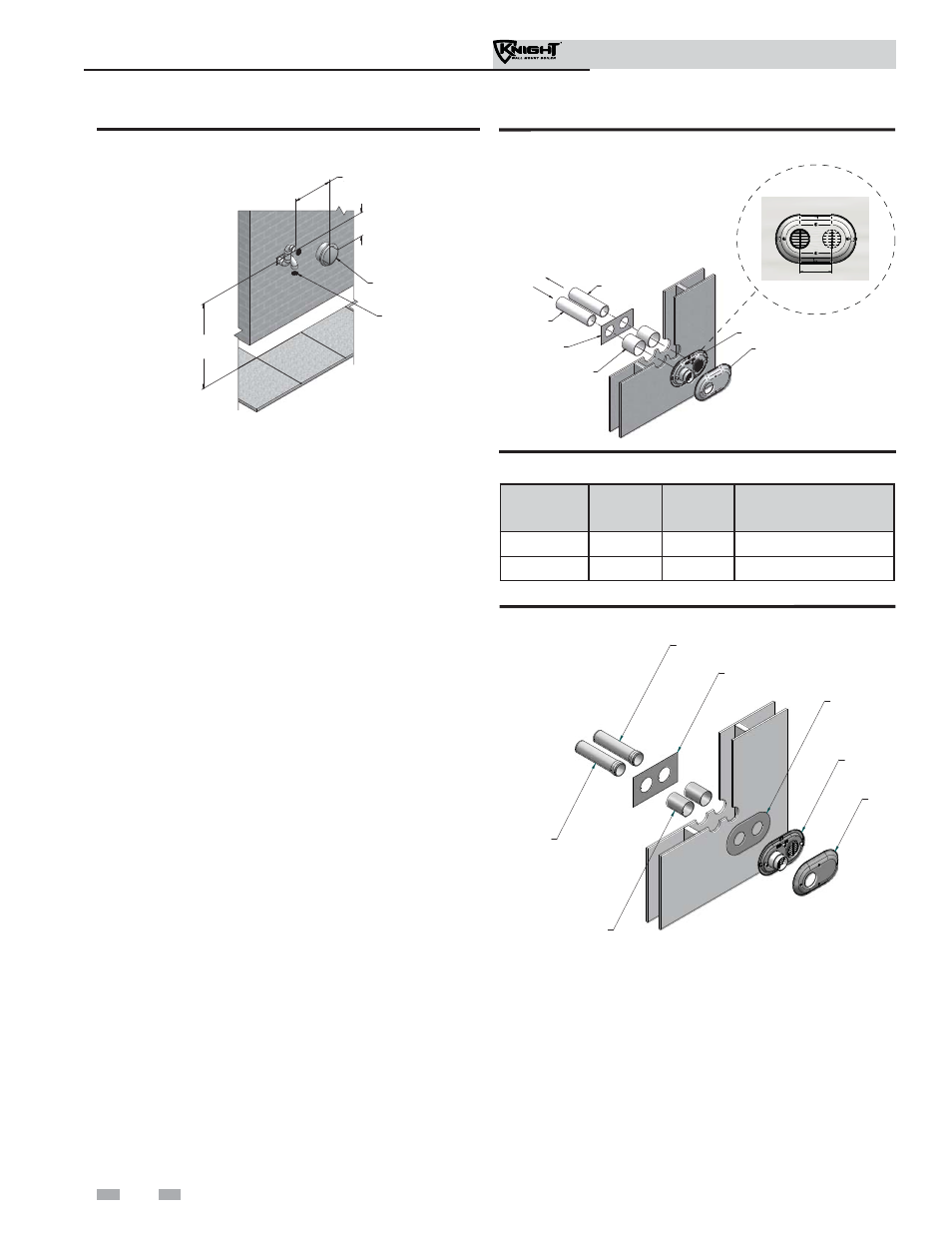

Figure 4-4A PVC/CPVC Sidewall Termination Assembly

Prepare wall penetrations

1. Use the factory supplied wall plate as a template to locate

the vent and air intake holes and mounting holes.

Air pipe penetration:

a. Cut a hole for the air pipe. Size the air pipe hole as

close as desired to the air pipe outside diameter.

Vent pipe penetration:

a. Cut a hole for the vent pipe. For either combustible

or noncombustible construction, size the vent pipe

hole with at least a 1/2 inch clearance around the

vent pipe outer diameter:

• 4½ inch hole for 3 inch vent pipe

• 5½ inch hole for 4 inch vent pipe

Drill 3/16" diameter holes for inserting the plastic anchors

into the wall.

2. For Polypropylene Only: Install the vent and air intake

sidewall adapters from Table 3F on page 20 into the vent

plate. Slide the sidewall retaining bracket down the

sidewall adapters flush to the vent plate (FIG. 4-4B).

3. For PVC/CPVC Only: Install the vent and air intake

piping through the wall into the vent plate openings.

Use RTV silicone sealant to seal the air pipe. Use the

cement/primer listed in Table 3D on page 19 to seal the

vent

pipe.

4. Mount and secure the vent plate to the wall, using stainless

steel

screws.

5. Seal all gaps between the pipes and wall. Seal around the

plate to the wall assuring no air gaps.

6. Assemble the vent cap to the vent plate (see FIG.'s 4-4A

and 4-4B). Insert the stainless steel screws into the vent

cap screw hole openings and securely attach the vent cap

to the vent plate.

7. Seal all wall cavities.

8. PVC/CPVC terminations are designed to accommodate

any wall thickness of standard constructions per the

directions found in this manual.

9. Stainless steel terminations are designed to penetrate

walls with a thickness up to 9.25 inches of standard

construction.

IF LESS

THAN 10’

36”

MIN.

FORCED AIR

INLET

BIRD

SCREEN

(TYPICAL)

7’ MIN. ABOVE ANY

PUBLIC WALKWAY

Figure 4-3B Alternate Clearance to Forced Air Inlets w/

Field Supplied Fittings

SIDEWALL

ADAPTER

(AIR)

SIDEWALL

ADAPTER

(VENT)

WALL

PLATE

GALVANIZED

THIMBLE

SIDEWALL

RETAINING

PLATE

VENT

PLATE

VENT

CAP

IMG00085

Figure 4-4B Polypropylene Sidewall Termination Assembly

Model

Air

Vent Centerline

Width

151 - 200

3"

3"

5 5/8"

286 4"

4"

5

5/8"

Table 4B Sidewall Vent Centerline Dimensions