2d. combustion and ventilation air supply, 2e. gas supply and piping – Laarsen Associates Lite 2 LG User Manual

Page 7

Model LG & LD Pool and Spa Heater

Page 5

without modification and in accordance with all local,

state, provincial and national codes.

Proper ventilation of exhaust and combustion air

are essential for the safe operation of the heater.

2D. Combustion and Ventilation Air

Supply

All indoor installations must have openings to

outside air for combustion, ventilation, and dilution of

flue gases from inside the building (see Figure 2 and

Table 1). Waterpik Laars does not recommend indoor

installations that do not provide combustion air from

outside the building.

All outdoor shelter installations (Canada only)

must have uninterrupted openings to outside air for

combustion and ventilation. The installation must be in

accordance with the latest edition of CAN/CGA B149.

Waterpik Laars does not recommend outdoor shelter

installations that depend on internal air for combustion.

Combustion air should be ducted to the heater from

outside the structure.

If the heater is installed in a residential garage, or

where flammable vapors will be present, the

burners must be 18 inches (457 mm) above the garage

floor. Refer to the latest edition of the National Fuel

Gas Code for more information. In Canada, refer to the

latest edition of the Gas Installation Code, CAN/CGA

B149.

2E. Gas Supply and Piping

2E-1. General Instructions

Review the following general instructions before

continuing the installation.

WARNING

Do not convert this heater from natural gas to

propane gas, or propane to natural. Field

conversion could create carbon monoxide gas

which can cause property damage, serious

injury, or death.

1.

Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1 and all

local codes. In Canada, the installation must be in

accordance with CAN- B149.1 or .2 and all local

codes that apply.

2.

Check the rating plate to make sure the heater is

fitted for the type of gas being used. Waterpik

Laars heaters, as shipped from the factory, are

certified to operate at an altitude of 0 to 3000 feet

(0 to 915 m) for natural gas and 0 to 5000 feet (0

to 1525 m) for propane gas in the United States.

Or if so ordered, at higher altitudes. For higher

altitudes, the heater manifold is marked with a

tag or sticker indicating one of the following high

altitude operation codes:

a. High altitude (H) - 3,000 to 6,000 feet (915 to

1,830 m) for natural gas and 5000 to 10,000

feet (1525 to 3050 m ) for propane gas.

b. High altitude (J) - 6,000 to 10,000 feet (1830

to 3,050 m)

3.

In Canada, the heater rating plate is marked for

specific altitude requirements: lo altitude is 0 to

2,000 feet (0 to 610 m) and high altitude (H) is

2,000 to 4,500 feet (610 to 1,370 m) above sea

level for natural gas and 0 to 4500 feet (0 to 1370

m) for propane gas.

4.

Use the figures in Table 3 to size the gas inlet

piping from the gas meter to the heater. Check all

local codes for compliance before installing the

heater.

Table 3. Natural Gas Pipe Size Requirements

Distance from Gas Meter

0-50 feet

50-100 feet

100-200 feet

Heater

(0-15 m)

(15-30 m)

(30-60 m)

Size

in.

(mm)

in.

(mm)

in.

(mm)

125

3/4

(19)

1

(25.4)

1

(25.4)

175

1

(25.4)

1

(25.4)

1-1/4

(31.75)

250

1

(25.4)

1-1/4 (31.75)

1-1/4

(31.75)

325

1-1/4 (31.75) 1-1/4 (31.75)

1-1/2

(38)

400

1-1/4 (31.75) 1-1/2

(38)

1-1/2

(38)

Notes:

1. These numbers are for natural gas (0.65 Sp. Gr.) and are

based on 1/2 inch (13 mm) water column pressure drop.

Check supply pressure with a manometer, and local code

requirements for variations. For liquefied petroleum gas,

reduce pipe diameter one size, but maintain a 3/4 inch

(13 mm) minimum diameter.

2. Check supply pressure and local code requirements

before proceeding with work.

3. Pipe fittings must be considered when determining gas

pipe sizing.

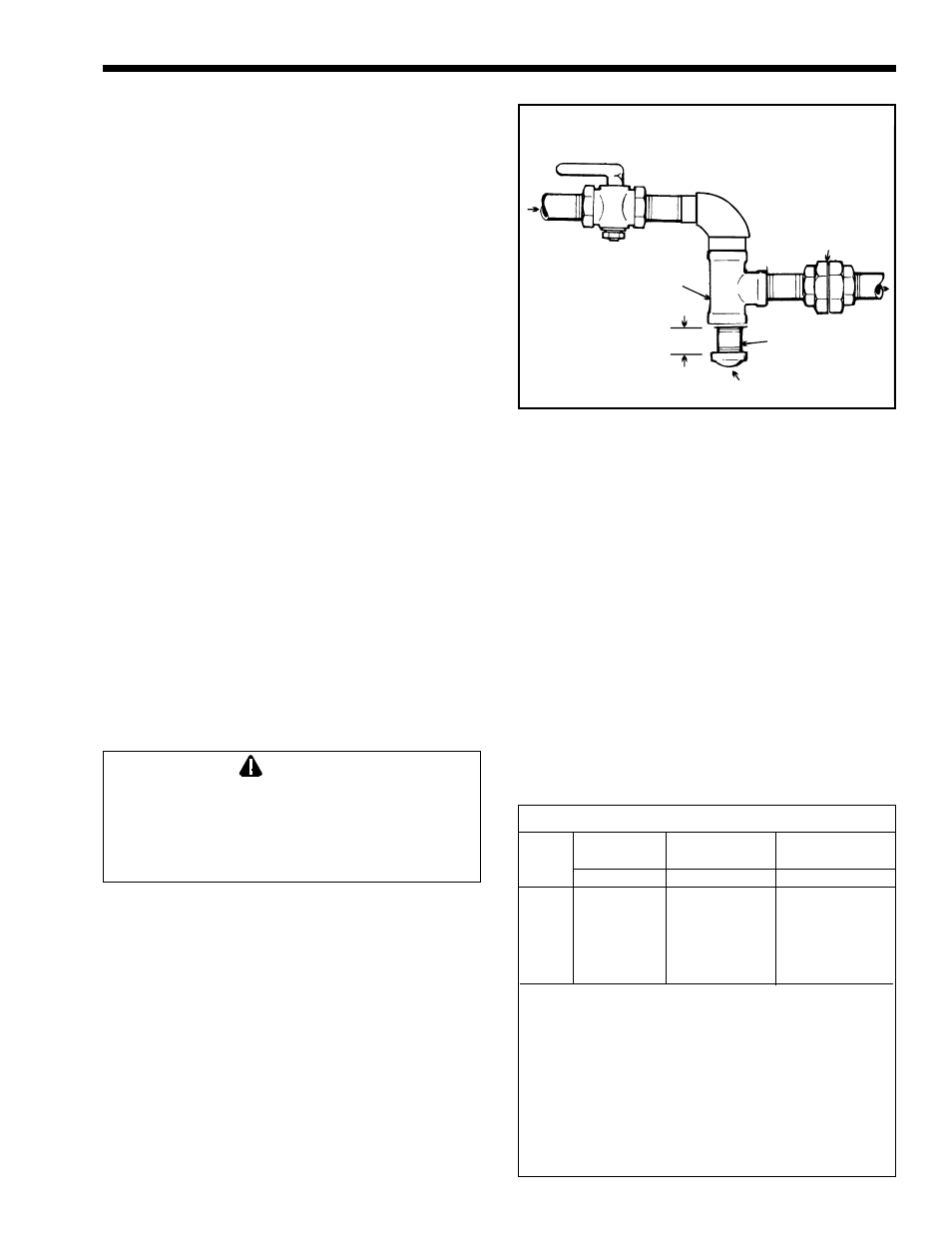

Manual Shutoff

Valve

Gas Supply

Inlet

To

Equipment

Inlet

Union

Cap

T-Fitting

3" Min.

(76 mm)

Nipple

Figure 5. The proper design for a sediment trap / drip

leg.