Tandem mig, Comparing high-deposition tandem mig, High-speed and high-deposition welding – Lincoln Electric Tandem MIG High-Speed and High-Deposition Welding User Manual

Page 8: Reduced heat input and improved bead profiles, Problem - single wire gmaw, Solution - tandem mig

Tandem MIG

T

h

e

f

u

t

u

r

e

o

f

w

e

l

d

i

n

g

i

s

h

e

r

e

.

®

APPLICATION

8/16

High-Speed and High-Deposition Welding

W A V E F O R M C O N T R O L T E C H N O L O G Y

T M

Reduced Heat Input and Improved Bead Profiles

Comparing High-Deposition Tandem MIG

To Single Wire GMAW Process

Problem - Single Wire GMAW

A single wire GMAW process has a useable weld

metal deposition rate based on wire feed speed and

wire diameter. In an attempt to increase weld metal

deposit rates, rather than push a given wire diameter

to unstable wire feed speeds, it is often common

practice to increase the wire diameter and operate

within stable wire feed ranges. The increase in wire

diameter increases the required current draw

associated with a given weld metal deposit rate.

Increased current draw produces higher heat inputs

leading to part distortion and a large fluid weld pool

that is difficult to control.

Solution - Tandem MIG

With the Tandem MIG process the two smaller

diameter electrodes produce a lower heat input and

improved weld pool control when compared to a larger

single electrode process attempting to perform similar

welds. When compared to larger diameter electrode

processes,Tandem MIG typically reduces heat input

by as much as 30-50%. The trail electrode in the

Tandem MIG process is operated in a special Tandem

MIG pulse mode designed to cool the weld pool

created by the lead electrode. The combination of

lower total heat input and the cooling affect of the trail

electrode, allows the trail electrode to be used to help

control weld bead contour. This provides the ability

to better stack horizontal weld beads and produce

flatter horizontal fillets while working at higher

deposition rates.

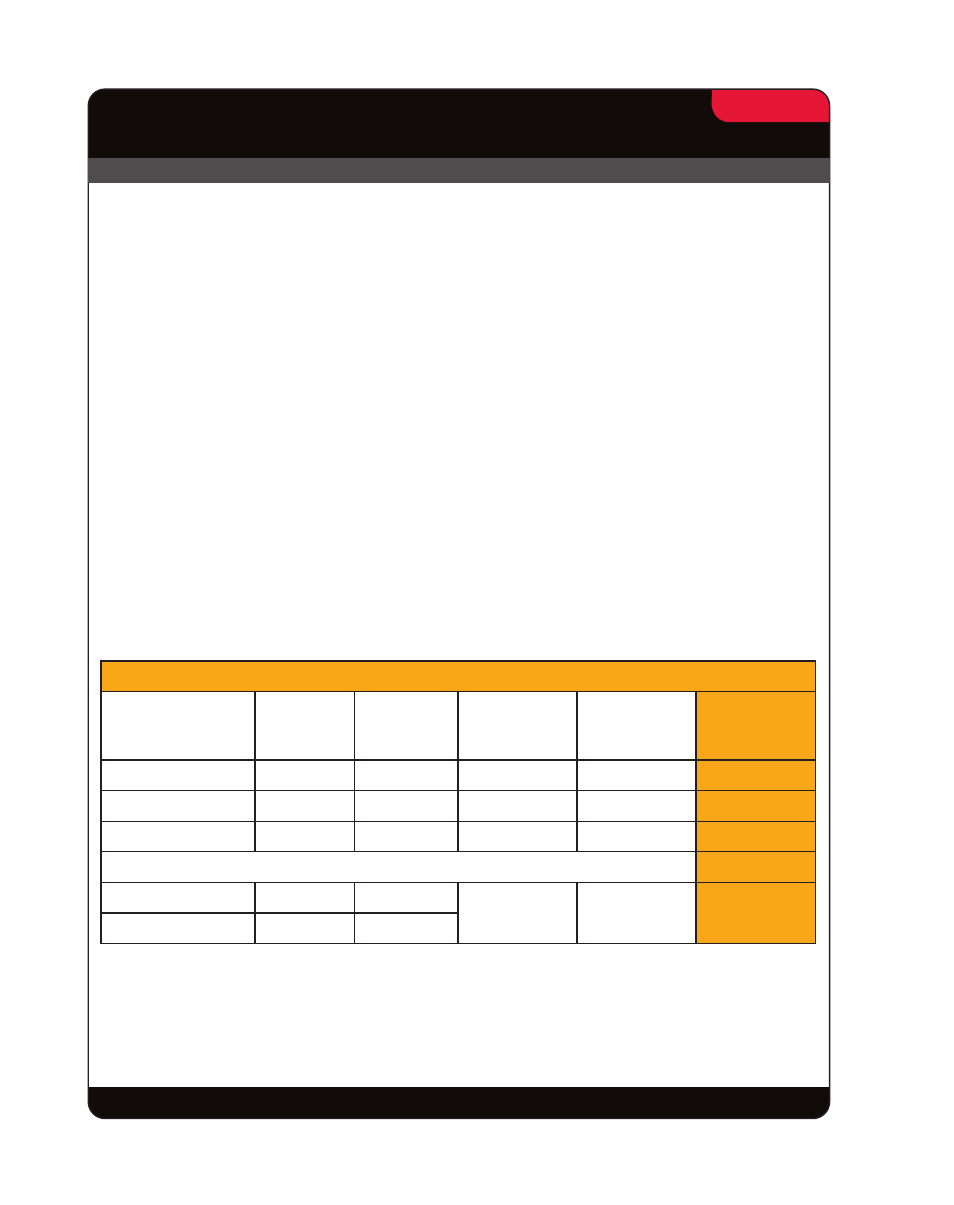

REDUCED HEAT INPUT EXAMPLE

5/16” Horizontal Fillet Weld

PROCESS

CURRENT

DRAW

(amps)

ARC

VOLTAGE

(DC+)

DEPOSIT

RATE

(lbs./hr)

TRAVEL SPEED

(ipm)

HEAT INPUT

Kj/in

GMAW - 1/16” dia. - ER70S - 6

470

31

17.8

17.7

49.4

FCAW - 3/32” dia. - ER70T - 1

435

29.5

15.8

15.7

49.0

GMAW - 3/32” dia. - ER70C - 6M

500

34

16.2

16.1

63.3

Tandem MIG

Lead .045” dia. ER70S - 6

300

23

23.3

23.1

33.5

Trail .045” dia. ER70S - 6

250

24