Tandem mig, Configuring tandem mig, High-speed and high-deposition welding – Lincoln Electric Tandem MIG High-Speed and High-Deposition Welding User Manual

Page 12

Tandem MIG

T

h

e

f

u

t

u

r

e

o

f

w

e

l

d

i

n

g

i

s

h

e

r

e

.

®

APPLICATION

12/16

High-Speed and High-Deposition Welding

W A V E F O R M C O N T R O L T E C H N O L O G Y

T M

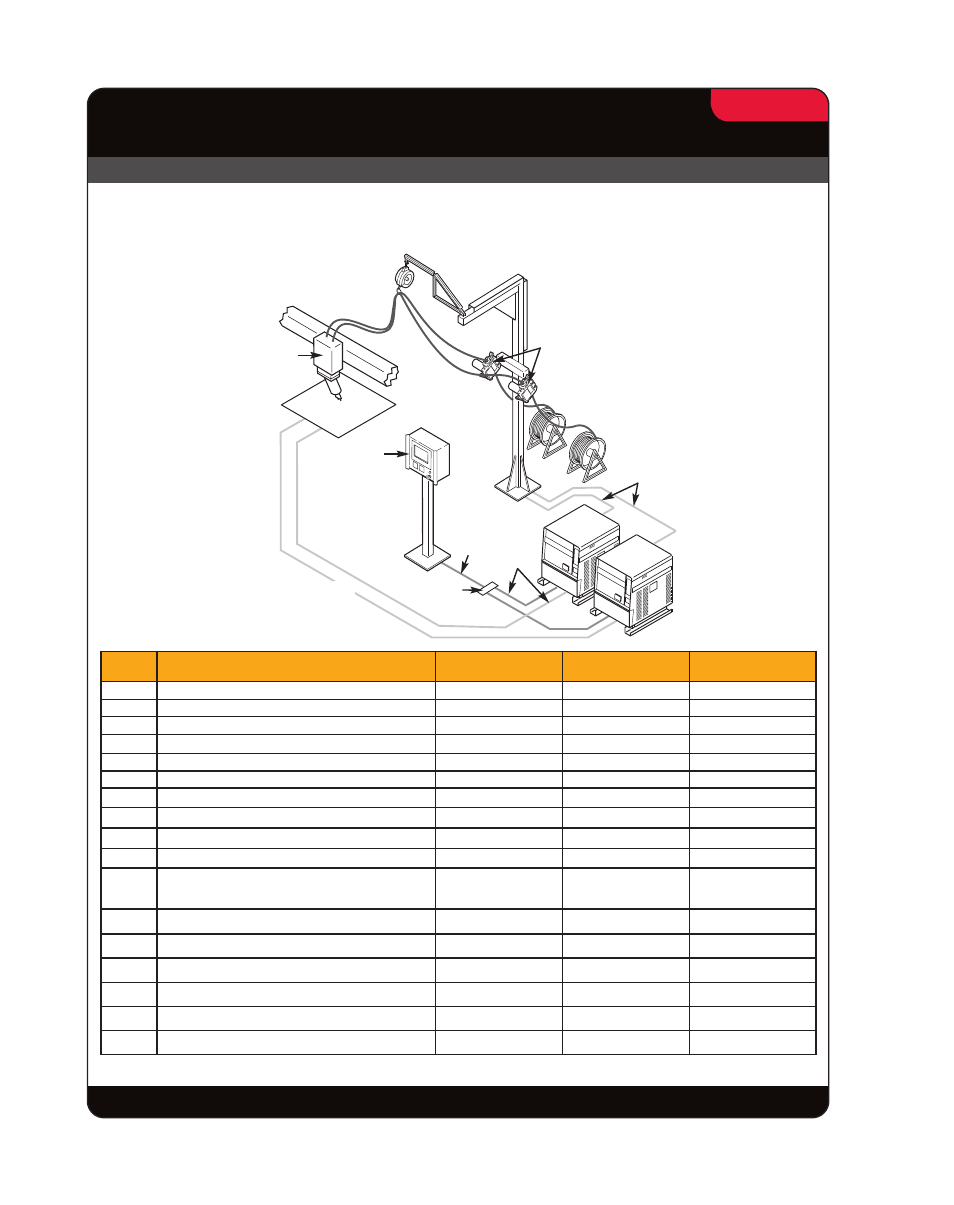

Configuring Tandem MIG

Hard Automation Systems

Models: AD1202 - 1 and AD1202 - 2

H

B

G

A

A

E

I

C

Item

Component

AD1202-1

AD1202-2

Qty

A

Power Source

Tandem MIG Power Wave 455M Robotic or

K2262-1-TM

2

Tandem MIG Power Wave 655 Robotic

K1519-1-TM

2

B

Wire Feeder

Power Feed 10R Wire Feeder

K1780-2

K1780-2

2

C

Interface Controller

G3207-185

G3207-185

1

D

DeviceNet Tee

S23383-3

S23383-3

2

Terminating Resistor

S23383-5

S23383-5

1

E

DeviceNet Communication Cables (drops) (20 in.)

S23383-4

S23383-4

2

F

DeviceNet Communication Cables (trunk line) (19.5 ft.)

S23383-2

S23383-2

1

G

Communication cables. Power source to wire feeders (25 ft.)

K1785-25

K1795-25

2

Cable jumper, 22 pin to 14 pin (18 inch)

K1804-2

2

H

800 amp Tandem MIG torch

or

900 amp Tandem MIG torch

S22693-XXX

or

G3494-XA

S22693-XXX

or

G3494-XA

1

I

4/0 Work (ground) cable (25 ft.)

L-4/0-25-14-14

L-4/0-25-14-14

2

Not Shown Drive Roll Kit

KP1505-XX

KP1505-XX

2

Not Shown Wire Straightener

K1733-1

K1733-1

2

Not Shown Process Sense Leads

K940-25

K940-25

2

Not Shown 4/0 Electrode Cable (25 ft.)

L-4/0-25-14-14

L-4/0-25-14-14

2

Not Shown Torch water cooling package

AD1013-3

AD1013-3

1 or 3*

* S22693-XXX series torches require (1) water cooling package per torch, G3494-XA series torches require (3)

D

F