P.c. board troubleshooting guide, Warning, Firing circuit p.c. board – Lincoln Electric IDEALARC IM318-B User Manual

Page 16: Outline for dc-1500 troubleshooting guide

P.C. BOARD TROUBLESHOOTING GUIDE

3. LED L3 indicates power is being applied to fault pro-

tection relay 2CR, when wire feeder button is pressed

or jumper is connected across 2 and 4.

4. LED L4 indicates when fault protection circuit is being

activated.

5. LED L5 indicates a control signal is being supplied to

the firing circuit. As the output control is varied, LED

L5 should change brilliancy.

FIRING CIRCUIT P.C. BOARD

Machine settings

Terminals #2 and #4 jumpered on

for P.C. board

DC-1500. Output Control at

troubleshooting

DC-1500. Variable Voltage opera-

tion.

All nine light emitting diodes must be lit when the power

source is turned on and the wire feed arc start button is

pressed or a jumper is connected between 2 and 4.

1. LED L7 indicates AC power being supplied to P.C. board

from control transformer T2. If not lit, check voltage

across terminals 203 and 204 on the terminal strip lo-

cated on the left side of the bottom fan baffle. Voltage

should be approximately 115 volts. If no voltage indi-

cates a supply problem, check wiring and transformer.

If voltage is present, turn the machine off, remove the

12-pin harness plug from the P.C. board, turn the ma-

chine back on and check the voltage across pins 2 and

3 on the plug. This should be approximately 115 volts.

If no voltage and there is voltage at terminals 203 and

204 on terminal strip TS-1 this indicates a broken lead

or loose terminal on either lead 203 or 204.If voltage is

present and LED L7 is not lit, replace P.C. board.

2. LED L8 indicates AC power being supplied to P.C. board

from control transformer T3. If not, follow the same

procedure as above in (1) for terminals 205 and 206 on

terminal strip TS-1 and pins 5 and 6 on the connector.

3. LED L9 indicates AC power being supplied to P.C. board

from control transformer T4. If not, follow the same

procedure as above in (1) for terminals 207 and 208 on

terminal strip TS-1 and pins 9 and 12 on the connector.

4. LED L1 through L6 indicate gate signals are being sup-

plied to the main power SCR’s L1 through L6 respec-

tively. If light L5 on the “Control/Fault Protection”

circuit P.C. board and lights L7 through L9 on the “Fir-

ing” circuit P.C. board are lit and LED’s L1 through L6

are not lit, check lead 231 between the “Firing” P.C.

board and the “Control/Fault Protection” P.C. board

that is not broken and is connected to each connector.

If the lead shows continuity and LED L1 through L6 are

not lit, replace the”Firing Circuit” P.C. board. If any

one of the LED’s L1 through L6 is not lit and lights L7

through L9 are lit, replace the “Firing Circuit” P.C.

board.

If troubleshooting guide indicates a possible P.C. board

problem, the guide on page ? can be used to locate the

problem.

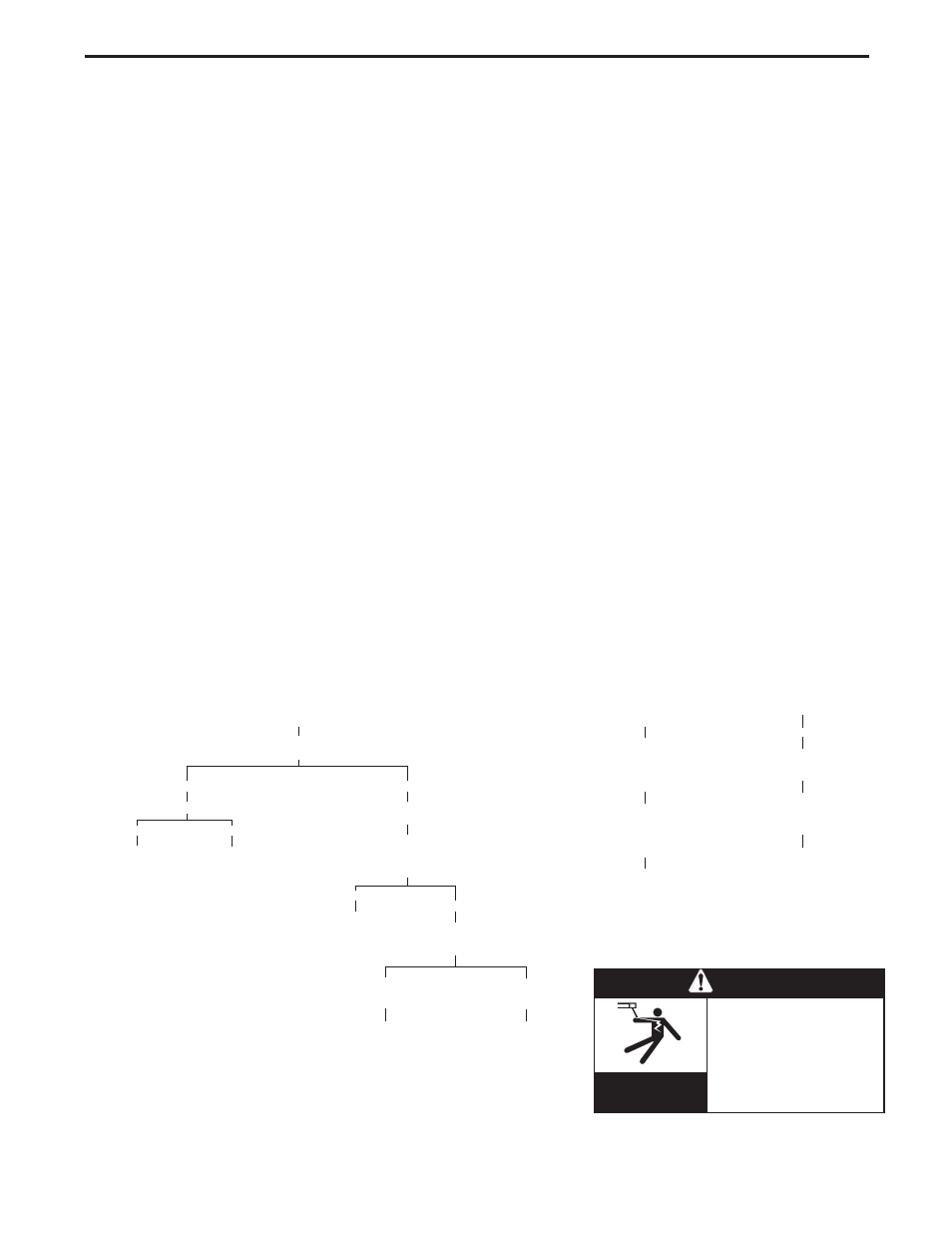

OUTLINE FOR DC-1500 TROUBLESHOOTING GUIDE

NO WELDER OUTPUT

MACHINE HAS OUTPUT BUT

ERRATIC WELDING

(INPUT CONTACTOR “ON” TERMINALS 2 AND 4 CLOSED)

TRIPS OFF IMMEDIATELY

CHECK PROCEDURE

CHECK CONTROL BOARD

CHECK FOR SHORT

LED L5

BETWEEN ELECTRODE AND

CHECK MODE SWITCH FOR

WORK LEADS, REMOVE

PROPER POSITION FOR

EXTERNAL LEADS FROM

PROCESS BEING USED

IF OFF

IF ON

THE OUTPUT TERMINALS

CHECK LED’S

CHECK LED L1

CHECK “FIRING” BOARD

IF TROUBLE STILL

L4, L5, L6

LED’S

PERSISTS,

FOR EQUAL

IF OFF

IF ON

CHECK LED L3 ON

BRILLIANCY

ALL

“CONTROL/FAULT

CHECK AC

REPLACE

NINE LIGHTS

PROTECTION” BOARD

IF LIGHTS ARE NOT ALL

INPUT TO

“CONTROL/

SHOULD

APPROXIMATELY EQUAL

“CONTROL/

FAULT

BE ON

IF LIGHT GOES ON,THEN

BRIGHT, REPLACE

FAULT

PROTECTION”

QUICKLY OUT WHEN START

FIRING P.C. BOARD

PROTECTION”

BOARD

IF YES

BUTTON IS PRESSED,

BOARD

IF NO

“CONTROL/FAULT

POSSIBLE

CHECK GATE

PROTECTION” BOARD IS

DEFECTIVE T7

LEAD

CHECK

DEFECTIVE AND SHOULD

TRANSFORMER

CONNECTIONS

LED’S

BE REPLACED

TO SCR’S

L7, L8, L9

IF ONE

IF ON AND

OR MORE

OTHER LIGHTS

ARE OUT

ARE OUT

CHECK AC

REPLACE

INPUT TO

FIRING

BOARD,

BOARD

203-204, 205-206

207-208

POSSIBLE

DEFECTIVE

TRANSFORMERS

T2, T3, OR T4

•

Have an electrician install and

service this equipment.

•

Turn the input power off at the

fuse box before working on

equipment.

•

Do not touch electrically hot parts.

ELECTRIC SHOCK

can kill.

WARNING

-14-