Operating instructions – Lincoln Electric IDEALARC IM318-B User Manual

Page 12

OPERATING INSTRUCTIONS

NL Option Kit

(Not Required With NA-3, NA-5, LT-7 or LT-56)

The K783 NL option kit (for field installation) is designed

to permit use of the NA-2, LAF-3, LT-3 and the LT-3 section

of the LT-34 tractor with DC-1500’s assigned code 7687

and above. It provides the necessary DC control power for

the operation of the equipment and the necessary circuitry

for proper inching, cold starting and arc striking. In using

the NL option kit a K775 remote field control is required and

is included as part of the option kit. (See pg 6, paragraph e.)

The NL option kit consists of a sheet metal box, 12.5” long,

11.5” deep and 5.7” high. This box mounts on top of the

DC-1500 and the following controls are located on the front

of the box:

1. Inch speed control — used for LT tractor only.

2. Hot start control — used to obtain optimum arc strik-

ing.

3. Polarity switch — changes polarity of control circuit to

correspond with electrode polarity.

4. Contactor dropout delay switch — switches in or out

a slight contactor dropout delay to prevent sticking of

the wire in the crater at the end of welding.

The terminal strip for connection to the automatic equip-

ment is located under the front cover. All necessary control

leads for connection to the DC-1500 are wired into the NL

kit for easy connection to the DC-1500 terminal strip.

Before proceeding with any installation, be certain the

DC-1500 is turned off.

1. Mount the NL option box to the top of the DC-1500

with the screws used to fasten the roof and sides.

2. Remove the cover of the NL option for access to the

terminal strip.

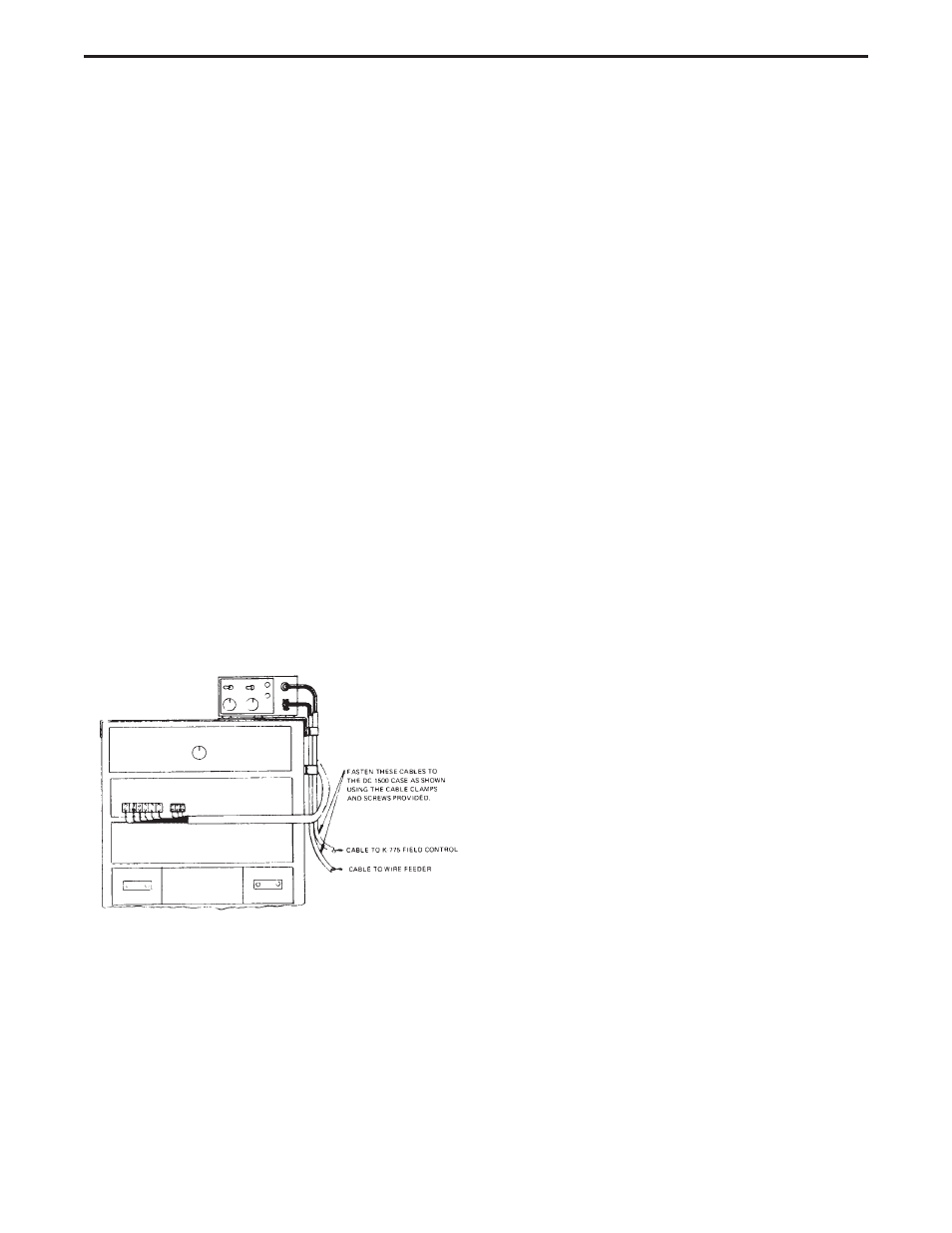

3. Feed the control cable from the automatic wire feed

control unit through the grommet on the front of the

NL box. Connect the control leads per the appropriate

connection diagram included at the back of this man-

ual. Secure the cables to the case with the clamps and

screws provided.

4. Using the same diagram, connect the leads from the

option kit to the DC-1500 terminal strip.

5. Feed the K775 control cable through the clamp on the

front of the NL option box and connect the leads to

terminals 75,76, and 77 per connection diagram.

6. Replace the cover. This completes the installation.

NOTE:

An NL Option was factory installed inside

DC-1500’s built to codes 7562-NL, 7636-NL and 7676-NL.

The instructions for the K783 apply except as follows:

1. The factory-installed NL Option does not have a sep-

arate “POS — NEG” switch.

2. The factory-installed NL Option does not have an “Inch

Speed” control.

3. It cannot be used with LT-3 or LT-34 wire feeders.

4. The fuse protecting the 115 volt DC circuit is a 2 amp

fuse located on the NL Option panel inside the welder.

Operation When Connected to the NA-2

1. Set the “POS — NEG” switch (on both NL Option &

DC-1500) to correspond to the polarity of the electrode

cable connection.

2. Set the mode switch on the front of the DC-15000 to

“Constant Voltage — Innershield” or “Constant Volt-

age — Sumerged Arc”.

3. Set the toggle switch on the front of the DC-1500 to

“Output Control Remote”.

4. Set the output as required for the procedures using the

K775 Remote Output Control shipped with the NL Op-

tion.

5. Set the NA-2 inch speed to a speed lower than welding

feed speed for good starting using the control on the

NA-2. The NL Option “Inch Speed” control is not in

the circuit.

6. Set the “Hot Start Control” on the NL Option to 4.

7. Set the “Contactor Drop-Out Delay” switch to “Off”.

Refer to the NA-2 Operating Manual for instructions

for setting the contactor drop-out delay and crater fill-

ing features built into the NA-2 circuit.

Operation When Connected to the LAF-3 and the K783

NL Option Kit

For proper arc striking and welding when using the LAF-3

with the DC-1500 and K783 NL Option Kit, follow the

instructions below (Turn the input power off at the fuse box

before working inside the machine.):

1. Connect the DC-1500 NL option, and LAF-3 per the

connection diagram M13321.

2. Remove the cover from the LAF-3 control box.

-10-