Operation – Lincoln Electric POWER WAVE F355I User Manual

Page 17

Non Synergic CV:

This type of CV mode behaves more like a conven-

tional CV power source. Voltage and WFS are inde-

pendent adjustments. Therefore to maintain the arc

characteristics, the operator must adjust the voltage to

compensate for any changes made to the WFS.

All CV Modes:

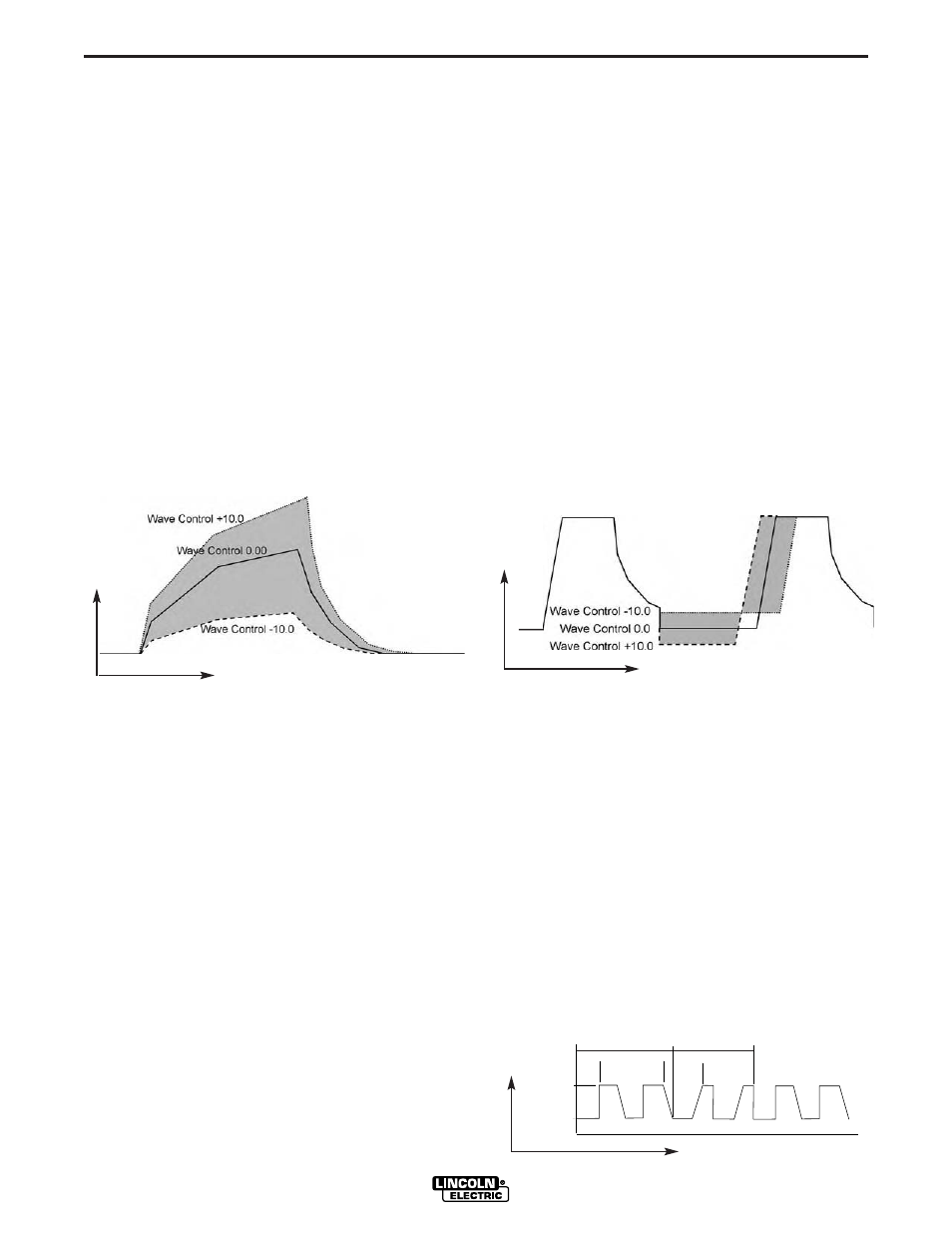

Arc Control, often referred to as wave control, adjusts

the inductance of the wave shape. The wave control

adjustment is similar to the "pinch" function in that it is

inversely proportional to inductance. Therefore,

increasing wave control greater than 0.0 results in a

harsher, colder arc while decreasing the wave control

to less than 0.0 provides a softer, hotter arc.

(See Figure B.2)

FIGURE B.2

Current

Time

CURRENT WAVE FORM (CV)

B-4

OPERATION

B-4

POWER WAVE F355i

The Power Wave utilizes "adaptive control" to com-

pensate for changes in electrical stick-out while weld-

ing. (Electrical stick-out is the distance from the con-

tact tip to the work piece.) The Power Wave wave-

forms are optimized for a 0.75" (19mm) stick-out. The

adaptive behavior supports a range of stickouts from

0.50" (13mm) to 1.25" (32mm). At very low or high

wire feed speeds, the adaptive range may be less due

to reaching physical limitations of the welding process.

Arc Control, often referred to as wave control, in pulse

programs usually adjusts the focus or shape of the

arc. Wave control values greater than 0.0 increase the

pulse frequency while decreasing the background cur-

rent, resulting in a tight, stiff arc best for high speed

sheet metal welding. Wave control values less than

0.0 decrease the pulse frequency while increasing the

background current, for a soft arc good for out-of-posi-

tion welding. (See Figure B.3)

PULSE-ON-PULSE™ (GMAW-PP)

Pulse on Pulse

™

is a Lincoln process specifically

designed for use in welding relatively thin (less than

1/4" thick) aluminum. It gives weld beads with very

consistent uniform ripple.

In Pulse on Pulse modes, two distinct pulse types are

used, instead of the single pulse type normally used in

GMAW-P. A number of high energy pulses are used

to obtain spray transfer and transfer metal across the

arc. Such pulses are shown in Figure B.4. After a

number "N" of such pulses, depending on the wire

feed speed used, an identical number "N" of low ener-

gy pulses are performed. These low energy pulses,

shown in Figure B.4, do not transfer any filler metal

across the arc and help to cool the arc and keep the

heat input low.

FIGURE B.3

Current

Time

CURRENT WAVE FORM (PULSE)

PULSE WELDING

Pulse welding procedures are set by controlling an

overall "arc length" variable. When pulse welding, the

arc voltage is highly dependent upon the waveform.

The peak current, back ground current, rise time, fall

time and pulse frequency all affect the voltage. The

exact voltage for a given wire feed speed can only be

predicted when all the pulsing waveform parameters

are known. Using a preset voltage becomes impracti-

cal, and instead the arc length is set by adjusting

"trim".

Trim adjusts the arc length and ranges from 0.50 to

1.50, with a nominal value of 1.00. Trim values greater

than 1.00 increase the arc length, while values less

than 1.00 decrease the arc length.

Most pulse welding programs are synergic. As the

wire feed speed is adjusted, the Power Wave will

automatically recalculate the waveform parameters to

maintain similar arc properties.

PEAK

AMPS

BACKGROUND

AMPS

TIME

HIGH HEAT

PULSES

LOW HEAT

PULSES

"N" PULSES

"N" PULSES

Current

FIGURE B.4