Lincoln Electric Mobiflex 200-M User Manual

Statiflex, Stationary fume extractor

ENGINE DRIVEN WELDERS

Publication E13.14

2/07

Web Update

5/08

www.lincolnelectric.com

Statiflex

™

200-M

Stationary Fume Extractor

ENVIRONMENTAL SYSTEMS

Advantage Lincoln

• Generous 735 CFM airflow with LFA 3.1/4.1 extraction arm and

SF2400 fan

(1)

.

• Filter efficiency up to 99%

(2)

.

• 50 m

2

(164 ft

2

) LongLife

®

filter with ExtraCoat

®

pretreatment.

• Pressure differential filter indicator gauges amount of particulate

build-up in filter cartridge, indicating system maintenance and filter

replacement.

• Suitable for a single or dual arm system configuration.

• Internal aluminum mesh spark arrestor.

• One-year warranty on equipment; 30 days on filter cartridge.

Statiflex

™

200-M System includes:

• Single Arm Unit: Filter, plastic housing, one 152 mm (6 in.) 1 meter

(4 ft.) hose, two hose clamps, instruction manual and wall-mounting

bracket.

• Dual Arm Unit: Filter, plastic housing, two 152 mm (6 in.) 1 meter

(4 ft.) hoses, two non-return valves, four hose clamps, instruction

manual and wall-mounting bracket.

NOTE: Stationary Fan Unit(s) and Extraction Arm(s) of your choice are required.

(1)CFM level is dependent upon arm length, fan type and system maintenance.

(2)

Per Din EN 60335-2-69 Standards.

Lincoln Electric’s

®

Statiflex

™

200-M is a wall mounted, low vacuum/high volume system designed for

medium duty extraction and filtration of welding fumes.

The Statiflex

™

200-M is ideal for a variety of facilities in which floor space is a premium including:

maintenance departments, general fabrication and welding job shops, weld schools, and industrial

welding environments.

The Statiflex

™

200-M can be configured as a single or dual arm system. Lincoln Electric’s

®

fume

extraction arms are designed to provide welders optimal motion and reach for their specific welding

position(s) and work area. The arm lengths range from 1 m (3 ft.) to 8 m (27 ft.) with optional EC4

extension crane.

The Statiflex

™

200-M with required stationary fan is designed specifically for weld

applications. The stationary fan units extract weld fume through the arm, and exhaust fumes

into the Statiflex

™

200-M filter unit. The internal spark arrestor and unique LongLife

®

filter

cartridge captures the welding fume particulate. The particulate is collected on the inside

of the cartridge, minimizing exposure to particulate during filter maintenance and disposal.

The Statiflex

™

200-M “single arm” filter system is recommended for consumable use of

approximately 1500 lbs. (680 kg) of MIG wire or 1100 lbs. (500 kg) of stick or flux-cored wire

before replacing.

The Statiflex

™

200-M “dual arm” filter system is recommended for consumable use of approximately

750 lbs. (340 kg) of MIG wire or 550 lbs. (250 kg) of stick or flux-cored wrie before replacing.

Filter performance will be affected by process and application variables including: base

metal(s), consumables(s), and coatings (oil) if applicable.

Processes

Stick, TIG, MIG, Flux-Cored

TECHNICAL SPECIFICATIONS

Dimensions

Product

Product

Filter Surface

H x W x D

Net Weight

Name

Number

Filter Type

m

2

(ft.

2

)

mm (in.)

kg (lbs.)

Statiflex

™

200-M

K1654-1

Pretreated Cellulose

50

900 x 810 x 730

30

Base Unit

(164)

(36 x 32 x 29)

(66)

Statiflex

™

200-M

K1654-2

Pretreated Cellulose

50

900 x 810 x 730

30

Dual Arm

(164)

(36 x 32 x 29)

(66)

Base Unit

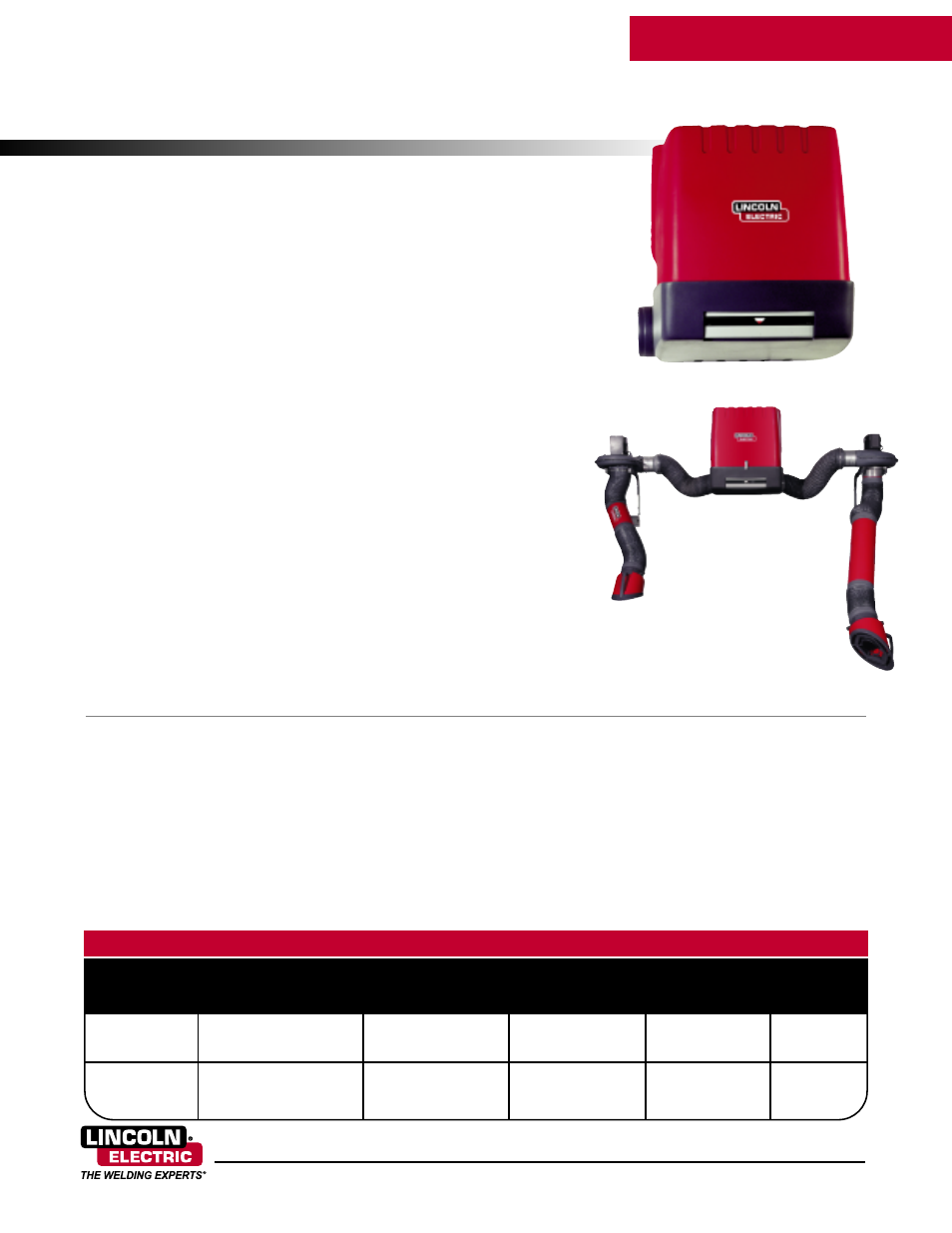

Shown:

Dual Arm Unit with optional

Fan Unit(s) and Extraction Arm(s)

Shown:

Base Filter Unit