Step 9. connecting gas line, Figure 18, Figure 16 figure 17 – Lennox Hearth ELITE EDVI25 User Manual

Page 11: Step 10. purging air

11

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

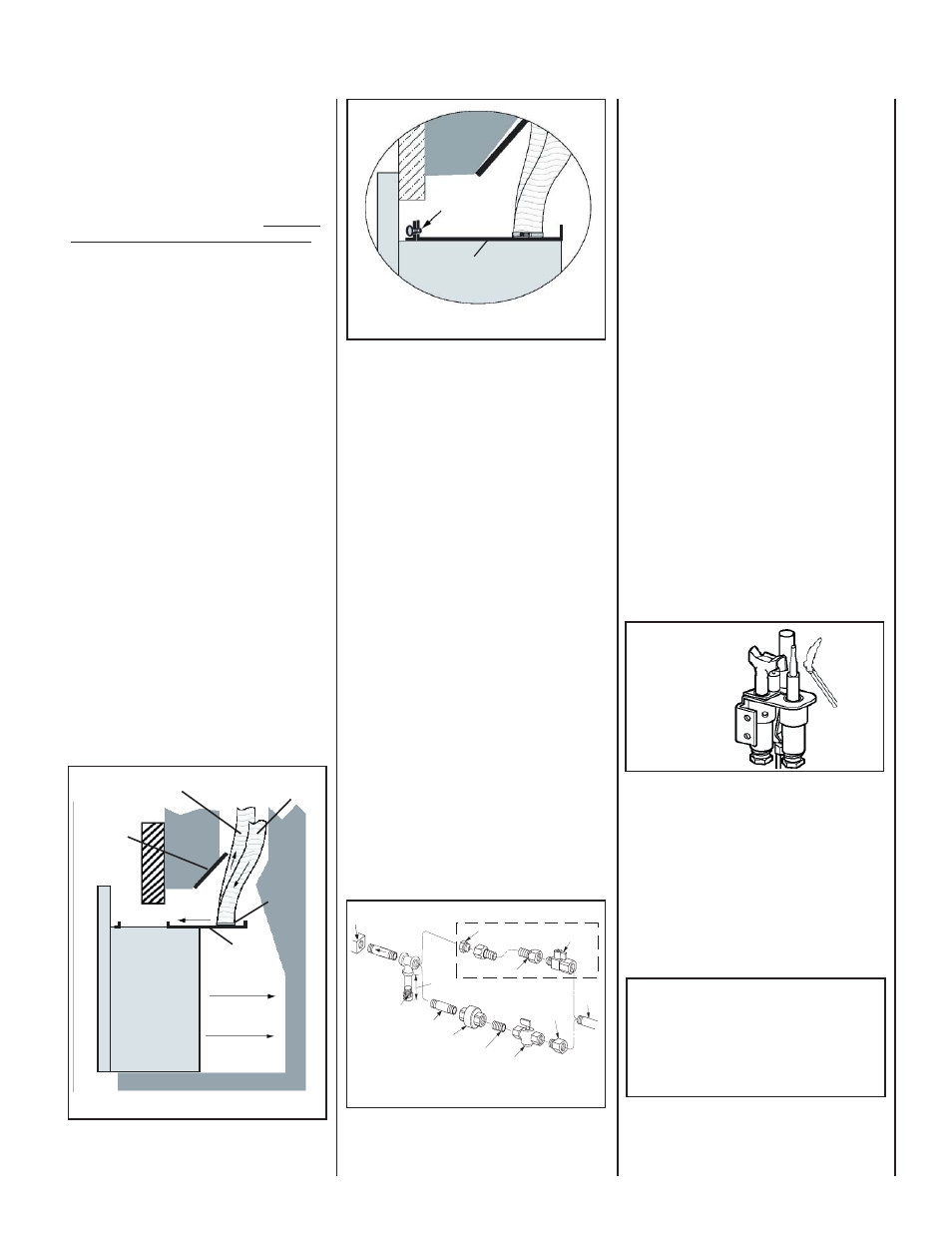

Make gas line connections. All codes require a

shut-off valve mounted in the supply line. Figure

18 illustrates two methods for connecting the

gas supply. The fl ex-line method is acceptable

in the U.S., however, Canadian requirements

vary depending on locality. Installation must

be in compliance with local codes.

Step 9. CONNECTING GAS LINE

Gas

Stub

¹ ₂" x

³ ₈" Flare

Shut-Off Valve

³ ₈" Flex Tubing

³ ₈" NPT x

Flare Fitting

³ ₈

³ ₈"

5NION

³ ₈

³ ₈

¹ ₂

x

³ ₈

"

Reducer

Gas

Valve

Gas Flex Line Connector

3EDIMENT

Figure 18 -

GAS CONNECTION

When fi rst lighting the appliance, it will take

a few minutes for the line to purge air from

the appliance. Once purging is complete, the

pilot and burner will light and operate as indi-

cated in the instruction manual. Subsequent

lightings of the appliance will not require such

purging. Inspect the pilot fl ame (remove logs,

if necessary, handling carefully).

Damper

Gear Clamp

Liner

Connector

Plate

Combustion

Air (inlet)

Exhaust (outlet)

Figure 16

Figure 17

Screw

Notes:

• Final gas connection should be made after

unit is in place to avoid damage to line when

pushing the unit into position.

• Mill-pac, high temperature silicone and/or

screws may also be used to secure the liners

to the collars (gear clamps must also be

used).

These appliances are equipped with a gas

fl ex line for use (where permitted) in con-

necting the unit to the gas line. A gas fl ex

line is provided to aid in attaching the appli-

ance to the gas supply. The gas fl ex line

can only be used where local codes permit.

See Figure 18 for fl ex line description. The

fl ex line is rated for both natural and pro-

pane gas. A manual shut off valve is also

provided with the fl ex line. The gas control

valve is located in the lower control compart-

ment. The millivolt control valve has a 3/8"

(10 mm) NPT thread inlet port fi tting.

Purging Air from Supply Line

a. Turn gas supply line valve off.

b. Loosen setscrew at inlet pressure tap on

control valve (see Figure 36).

c. Turn gas supply line valve on.

d. When gas fl ows, turn supply valve off.

e. Close the inlet pressure tap.

Figure 19

Step 11. INSTALLING LOGS, VERMICU-

LITE AND EMBERS

The packaged log set, vermiculite and embers

are located within the fi rebox of the insert.

Note: The EDVI25/EDVI30 log set is shown

in fi gures 20-28 and the EDVI35 log set is

shown in fi gures 29-34.

Installation Instructions:

Purging Air from Appliance

Purge air from appliance by holding gas

control valve down in the pilot position

until pilot will light (see Figure 19). DO NOT

LIGHT A MATCH IF YOU SMELL GAS. Light

a match then allow gas fl ow to pilot. If the

Match “blows”, there is air in the line (purge

line). If the fl ame is straight and tall, there is

no gas pressure.

Liner

Connector

Plate

Note: If an optional Brick Liner Kit was

purchased, intall it now, per instructions

provided in kit.

Flex Liner Installation (see Figure 14 for

Masonry Fireplace Installations and Figure

15 for Factory Built Fireplaces):

Note: Refer to Vent Manufacturer Instal-

lation Instructions.

1) Cut the fl ex liners as required (mark both

ends of one of the fl exible liners as INLET).

2) Connect the liner marked INLET to the inlet

side of the termination adaptor. Connect the

other liner to the exhaust side. Secure liner

to INLET collar with hose clamp.

3) Install fl ashing.

4) Insert both liners into chimney, passing

through the damper opening.

5) Install termination cap.

6) Remove the liner connector plate from the

insert top (by removing the screw shown in

Figure 17, then sliding plate backward until it

clears the retaining breackets). Liners should be

streched just enough to prevent the possibility

of sagging or coiling in the fl ue. Cut off excess

liner (see collar locations on pages 5 & 6).

7) Connect the liner marked INLET to the inlet

collar on the liner connector plate (marked

with an "I"). Connect the remaining liner to

the exhaust collar (marked with an "E") on

the liner connector plate.

Note: Both con-

nections should be secured to collars using

gear clamps.

8) Slide the liner connector plate all the way

forward and secure into place with a screw

(provided) as shown in Figure 16 & 17.

WARNING: If logs are not installed accord-

ing to the directions shown here, fl ame

impingement and improper combustion

could occur and result in soot and/or exces-

sive production of carbon monoxide (CO),

a colorless, odorless, toxic gas.

AIR PURGING PROCEDURES MUST BE

PERFORMED BY A QUALIFIED TECHNICIAN

ONLY.

Step 10. PURGING AIR