Piping – Lochinvar SSS031 User Manual

Page 6

Installation & Operation Manual

6

Boiler Side Piping

Figures 3-1 thru 3-3 show typical boiler side piping for

several common situations. Regardless of which system is

used it is imperative that the flow rates called for in Table 3A

on page 6 are developed through the coil. This requires

properly sized piping and a properly sized pump.

The system shown in FIG’s 3-1 thru 3-3 are described below:

Zone with Circulator to Aquastat

This system is like the circulator zone system on a straight

heat job except that one of the zones goes to the tank instead

of radiation. As on any circulator zone system check valves

should be installed in each zone to prevent unwanted

circulation through zones which are not calling for heat.

Figure 3-1 on page 7 illustrates typical circulator zone

piping.

Zone with Valve to Aquastat

As with the circulator zone system, this system is just like a

standard heating zone system except that one of the zones is

connected to the tank coil as shown in FIG. 3-2. The

circulator must be large enough to move boiler water

through the coil regardless of the flow rate required through

the heating zones.

3

Piping

DHW Prioritization

This piping system is designed to provide direct hot water

priority over the other zones in the heating system. When there

is a Domestic Hot Water (DHW) call for heat, the Knight control

will shut off the boiler circulator and activate the domestic hot

water circulator. Once the DHW demand is satisfied, the boiler

circulator will be readjusted as demand requires. The circulator

must be large enough to move the boiler water through the coils.

The recommended piping for a DHW priority system is depicted

in FIG. 3-3 on page 8.

Multiple Tank Connections (Boiler Side)

Multiple tank installations must be done in the “reverse-return”

manner. The reason for this is to create the same pressure drop

(and therefore, the same flow) through the coil of each tank.

The boiler manifold piping must be sized so that each coil has

the flow rate called for in Table 3A below. For example, if two

tanks are to be manifolded together, the circulator and zone

piping common to both tanks must be capable of moving

16 GPM (2 x 8 GPM), see FIG. 3-4 on page 9.

Because the pressure drop through tank coils varies from size to

size, it is hard to predict the flow rate that will be developed

through each coil when two tanks of different sizes are placed in

the same manifold. For this reason it is best not to mix tanks of

two different sizes in the same zone if their recovery is critical.

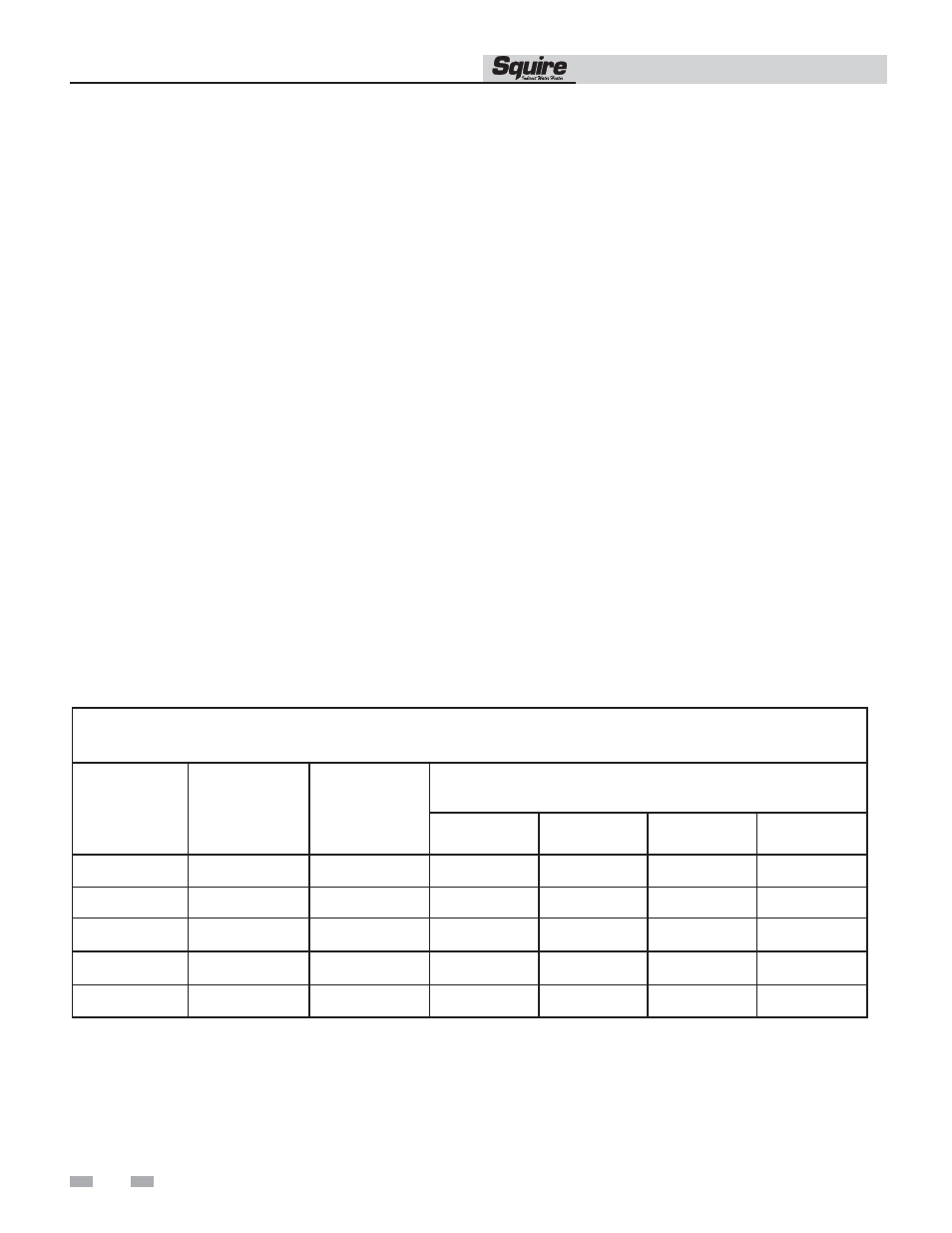

Table 3A

Pressure Drop Values

Model

Coil

Length (FT)

Tube

Diameter (IN)

Pressure Drop

(FT/HD)

8 GPM

12 GPM

16 GPM

20 GPM

SSS031

22.0

1 1/4

1.4

3.0

5.1

7.8

SSS041

27.6

1 1/4

1.7

4.0

6.4

9.8

SSS051

32.8

1 1/4

2.0

4.4

7.6

11.7

SSS081

49.2

1 1/4

N/A

6.3

10.9

16.7

SSS119

65.6

1 1/4

N/A

N/A

15.3

23.5