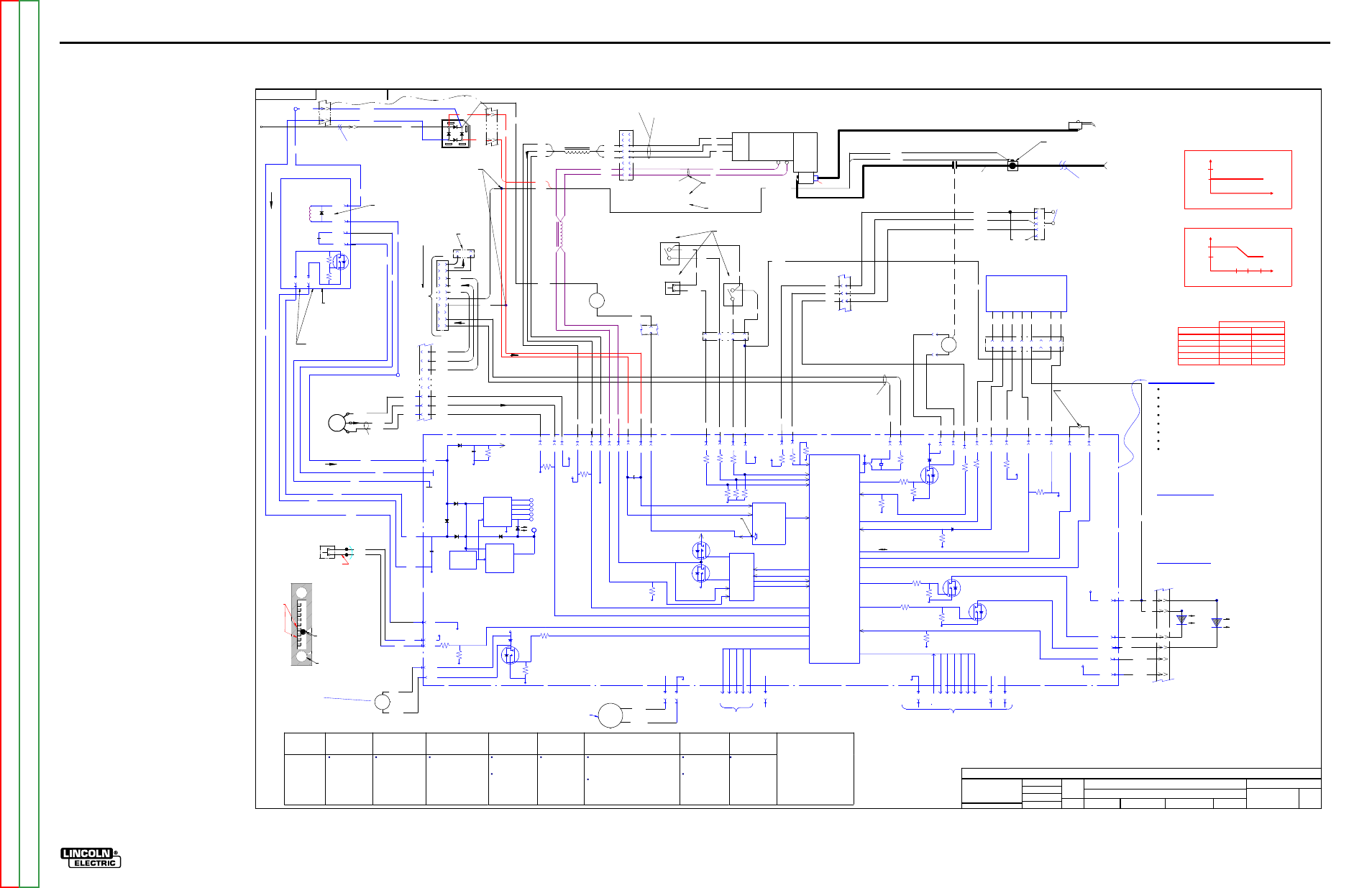

Ln-25 pro wire feeder, Electrical diagrams, G-10 – Lincoln Electric LN-25 SVM179-B User Manual

Page 88: Ln-25™ pro

ElECTriCal DiaGrams

G-10

lN-25™ prO

sChEmaTiC - lN-25 prO - COmplETE maChiNE CODEs 11620, 11621, 11716, 11717 - (G5683-2) pG1

G5683-2

LN-25 PRO ANALOG

MACHINE SCHEMATIC

NONE

G5683-1

DO NOT SCALE THIS DRAWING

EQUIPMENT TYPE:

SUBJECT:

SCALE:

UF

CRM40943

1

PAGE ___ OF ___

2

ENGINEERING CONTROLLED

MANUFACTURER:

No

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

t

MATERIAL TOLERANCE (" ") TO AGREE

WITH PUBLISHED STANDARDS.

ON ALL ANGLES IS ± .5 OF A DEGREE

ON 3 PLACE DECIMALS IS ± .002 in. (± 0.05 mm)

ON 2 PLACE DECIMALS IS ± .02 in. (± 0.5 mm)

UNLESS OTHERWISE SPECIFIED TOLERANCE:

MANUFACTURING TOLERANCE PER E2056

RELEASED A.03 FROM "X".

CHANGE DETAIL:

REFERENCE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

IF PRINTED

@ A1 SIZE

UNITS:

INCH

11/6/2009

tpearn

ENYEDY

BS

DRAWN BY:

ENGINEER:

CLEVELAND

APPROVED:

CONTROL:

A

G56

83

-2

LN-25 PRO WIRE FEEDER

Start-Up

On power-up, the LN-25 PRO will light the motor thermal LED and

polarity LED 2-3 seconds.

If the feeder is powered-up with the trigger depressed, welding will

not start until the trigger is released and then depressed again.

Notes:

Motor overcurrent limit varies with WFS.

FEED

PLATE

67C & 67D

J4-10

1

4

3

2

6

5

P9

8

7

MOTOR /

GEARBOX

W

B

551

550

531

L4

537

534

72 HZ TO 1.2 KHZ

R-B 15.0 VDC

B-U 6.2 VDC ANY SPEED

(METER DEPENDENT)

Motor is located

behind

glastic panel

Gearbox ratio is 23.5:1

Motor case is at

electrode potential

From Power Source

(Electrode Connection)

J4-7

0-5V PULSE SIGNAL

FREQUENCY = SPEED

WIRE FEED

SPEED

0V = MIN SPEED

5V = MAX SPEED

GAS PURGE

FLEXIBLE POWER P.C. BOARD

SCHEMATIC = G4783

Top of motor

Motor resistance

is 1.5 ohms

Leads Pass through

toroid 2 times.

R

U

B

Located on

Case front

Leads Pass

through

toroid 2 times.

ISOLATED 2-4 TO

POWER SOURCE

BLACK

RED

FAN

+

-

S4

GAS PURGE

PUSHBUTTON

SWITCH (N.O.)

612

610

13.5 VDC WHEN

NOT DEPRESSED

J6-1

J6-7

J2-1

(LOCATED INSIDEOF

CONTROL BOX)

FAN BLOWS AIR ACROSS

CONTROL PC BOARD

CONTINOUSLY AT 6200 RPMS.

GAS

SOLENOID

690

691

J4-4

J4-3

J2-5

100K

ohm

+15V

J3-7

+5V

J3

-1

J3

-2

J3

-3

J3

-4

J3

-5

PROGRAMMING PCB

FACTORY USE ONLY

GAS SOLENOID

-

+

WORK

CLIP

+35V

POWER

SUPPLY

POWER

SUPPLY

+5V SPI

+15V SPI

OVER

VOLTAGE

PROTECTION

ISO

LED

35VDC

+5VDC

+15V ISO

-15V

COM

MOTOR

SUPPLY

COM

J5-1

J5-8

621A

Located on Case Front

J4-11 J4-12 J4-6

100K

ohm

+5V

J3-6

J3-8

+5V SPI

J4-9

10K

ohm

+15V

COM

534

537

531

J4-1

J4-2

550

551

TACH

FEEDBACK

Model

Ranger 8,9

Classic

Ranger 250, 305

Commander 300,400,500

(Common Analog

Controls)

V350

(Common Digital

Controls)

DC-400, 600

Square Wave TIG 300/355

Miller Inverters

STT II

K2613-1

K2613-2

Recommended

all CV

operation.

Recommended for

CV operation.

(Wire Feed

Module Required)

Recommended for CV

operation.

Recommended

for CV

operation.

May be used for

pulse welding if

the welding

procedure is

qualified by the

customer.

Recommended

for CV and CC

operation.

Not recommended for CC operation

because the customer may

experience short contactor life from

inductive nature of the power source.

Not recommended with high frequency

TIG starti ng.

Recommended

for CV voltage

sense operation.

Not

recommended for

use when pulse

welding.

Not recommended

for STT operation.

Note:

Most semiautomatic wire

welding processes perform

better using constant voltage

power sources. Be sure the

proper power source is used

for your application. Contactor

life may be shortened in

applications using CC

machines with high OCV.

J5-6

J5-7

21D

67F

721

J5-5

ANALOG

VOLTMETER

667B

721

-

+

TRIGGER

-15

+15

721 IS DRIVEN NEGATIVE TO COMPENSATE

FOR THE METER FOR DIODE DROP ERROR

ON THE BRIDGE

METER

COMPENSATION

CIRCUIT

POLARITY

SENSE

PROGRAM

BURNBACK

MOTOR

DRIVE

CIRCUIT

MOTOR VOLTAGE

MOTOR CURRENT

BRAKE

DRIVE

BRAKE

DRIVE

PWM

0.05K

ohm

L5

J6-3

J6-2

587

530

J6-4

523

J6-6

509A

+15V

COLD FEED

CC/VV

TRIGGER INTERLOCK / 2 STEP

S1, S2 & S3 Located

on Wire Drive Panel

CC

509D

CV

509E

TRIGGER INTERLOCK

(NOT PRESENT ON K2613-3)

S1

587

2-STEP

Located on Wire

Drive Panel

Trigger Interlock does not stop

welding when the arc is broken.

Pull and release to end the weld.

509B

S2

523

S3

COLD FEED

530A

509E

(LOCATED AT REAR

OF FEEDER)

667C

0V=COLD FEED

(N.O.)

15V=CV

0V=CC

15V=2 STEP

0V=TRIGGER

INTERLOCK

4B

606A

2

4

+15V

J5-4 J5-3

MOV

MACHINE

OUTPUT

ENABLE

CONTACTOR DRIVE

COM

+35V

J4-8 J4-5

CONTACTOR

4 O COIL

0 VDC OPEN

3 VDC CLOSED

12 VDC COIL

PWM CONTROLLED

507

578

20

ohm

0V = OFF

20msec ---- 250msec

605

601

J2-6 J2-3

608

607

J2-7

COM

YELLOW THERMAL LED

COM

POLARITY LED

J6-11

1W

J6-14

B

+5V SPI

GREEN

POLARITY

LED

YELLOW

MOTOR

THERMAL

LED

ARC ESTABLISHED

J1-2 J1-1

+5V SPI +15V

J1-10

J1

-8

J1

-6

J1

-5

J1

-4

J1

-9

J1

-3

J1

-7

SC

LK

CS

3

CS

2

CS

1

CS

0

M

O

SI

M

IS

O

SPI DIGITAlL COMMUNICATION

J6-8

-15V

GAS

ON - OFF

GAS

FLOW

ENABLE

Located under

Wire Drive Panel

(LOCATED AT OUTSIDE

REAR OF FEEDER)

10K/2W

0 VDC MIN. WFS

5 VDC MAX. WFS

WIRE FEED SPEED

CONTROL

POTENTIOMETER

621

667

11

10

P7

12

Connector located

behind case front

COM

15

14

(LOCATED AT TOP

FRONT OF FEEDER)

MICRO

CONTROLLER

COM

MOTOR

SUPPLY

6

8

7

5

1

3

4

6

2

8

7

9

10

J18

1

P16

Located on

top of motor

PLASTIC HOUSED BOLTED

CONNECTION (BASE CENTER)

TIMER KIT P.C. BOARD

(OPTIONAL)

SCHEMATIC = M21341

SEE PAGE 2

L12081 2.6 V @ 50 IPM

27 V @ 700 IPM

L13084 2.6 V @ 25 IPM

32 V @ 400 IPM

0V.=TRIGGER

CLOSED

15VDC.=TRIGGER

OPEN

Located on

Case Front

TRIGGER

INPUT

TRIGGER CONNECTOR

J14

622A

500A

E

B

C

D

A

P7-1

67D

67C

667B

67B

4

1

3

6

67C

67B

IN HARNESS

CENTER BASE

AREA

P7 = 16 PIN

P17 = 6 PIN (Both are located on lower front)

577A

576A

575A

577A

575A

576A

577A

576A

575A

77C

76C

75C

531

537

534

40V MAX.

21B

.05 uF

600 V

707

608

607

J2-8

4B

gun connector

4 of 4

3 of 4

J6-9 J6-10

622

500

+15V

2 of 2

P17

P7

1 of 4

P7

When tach feed back is lost,

the voltage to the motor is a

constant 10VDC.

(controlled by software)

P17

case front

strain rel

ief

1 of 2

5

2 of 4

copper bar

copper bar

weld cable

13

2B

1B

R1

D1

case back

strain rel

ief

509C

21A

21C

21E

JUMPER TOGETHER FOR

EXTRA TORQUE MACHINE

P60

3

4

5

6

7

8

601

509B

605

2

1

3

4

2

J2-2

+5V

606

EXTRA TORQUE

TAKEN WITH 40 V INPUT

IN CV MODE.

667A

WFS limited by arc voltage when operating across the arc

Feeder Input Volts Standard Gear Extra Torque

15

280

210

17

340

235

21

440

400

24

520

400

27

600

400

Maximum WFS

EXTRA

TORQUE

Control Board Summary

Converts arc power to a usable control circuit voltage.

Receives switch signals from Trigger, Cold Feed, Gas Purge

Reads WFS potentiometer.

Communicates with optional timer kit.

Controls motor speed with PWM.

Turns Gas Solenoid on, off, PWM.

Reads the motor tachometer.

Operating Voltage= 15-110 VDC.

Shut down Voltage= 130 VDC.

Thermal light turns on when shutdown voltage exceeded.

Code and Serial numbers are below Wire Drive on plastic

housing Nameplate.

Thermal “Yellow” Light

Motor Over Current

Motor and trigger disabled for 30 seconds.

Must retrigger to start welding after 30 seconds pass.

Shutdown Voltage exceeded

May occur with some inverters.

May occur with some CC machines with high

inductance.

Polarity “Green” Light

On= Positive Polarity

Off= Negative Polarity

708

J6-5

9

2W

J6-12

16

509B

The WFS range of the LN-25 PRO

Normal Speed = 40- 700 IPM.

Extra Torque = 25- 400 IPM.

Before 2-20-2009

After 2-20-2009

*Extra Torque

370

530

700

180*

257*

400*

3.5

4.5

3.5

4.5

Preset

WFS

Current

Level

Current

Level

Preset

WFS

77C

76C

75C

610

612

B1

B2

C2

C1

C1

C2

B1

B2

667D

667E

B2

B1

621

667D

25 TO 35

NORMAL

FLOW

RATE

GOOD FOR Ar, CO2,

CO2/Ar BLENDS

(OUTSIDE

BACK OF

CASE)

FLOW METER

22 O COIL

0 VDC OPEN

4 VDC CLOSED

12 VDC COIL

PWM CONTROLLED

BALL FLOAT

USE MIDDLE

OF BALL TO

SET

ADJUST VALVE

NOT PRESENT

ON S27505

J61-1

J61-3

J61-4

J61-2

J62-2

J62-1

MOTOR FILTER P.C.

BOARD SCHEMATIC=

S27592 BEFORE 6/15/2009

S27505 AFTER 6/15/2009

USED TO DISCHARGE

POWER SUPPLY CAP

AFTER A HIGH VOLTAGE

TRANSIENT. LATER

RELOCATED TO THE

CONTROL BOARD.

USED FOR FILTERING

INVERTER NOISE

J15

14 PIN REMOTE

LEADS ARE

PRESENT BUT

NOT USED IN

THIS UNIT.

NOT

USED

J2-10

555

622

500

4

2

555

3

555A

622B

G-10

NOTE:

This diagram is for reference only. It may not be accurate for all machines covered by this manual.