Operation, Figure b.2 – Lincoln Electric INVERTEC V450-PRO User Manual

Page 19

B-4

OPERATION

B-4

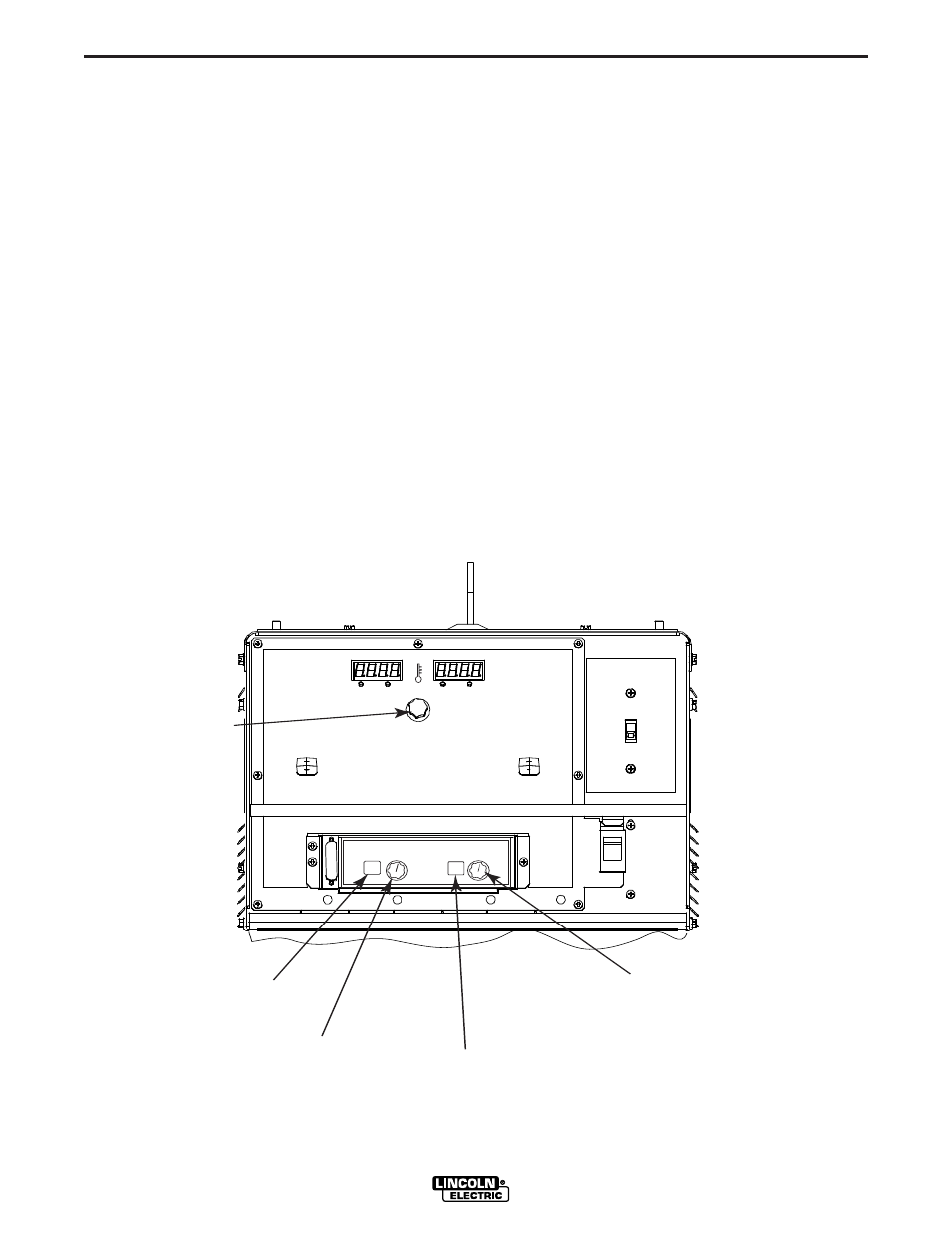

8A. WELD MODE SELECT-FOR

MACHINES EQUIPPED WITH OPTIONAL

ADVANCED PROCESS PANEL

(See Figure B.2 UPPER AND MIDDLE SECTION)

See (WELD MODE DETAILS) in this section.

Select knob is used to scroll through all Welding

modes. The Memory button is used to store and/or

access Welding information into locations M1 thru M8.

Modes:

In addition to the 5 welding modes described in SEC-

TION 7, the Advance Process Panel allows you to

select the Following additional modes.

•

Constant Power mode

In the Power Mode;

The work point will be in the Volts window. The

Amp window will have CP displayed indicating

Constant Power. Once current starts flowing and

during the 5 second

“

Hold

”

feature the displays will

show Volts and Amps respectively.

IINVERTEC V450-PRO (CE)

•

Gouge Mode

The gouging mode is specifically designed for car-

bon arc gouging with electrodes up to 3/8

”

.

•

Pulsed Modes

In Pulse Modes;

The work point will be in the Amps window and

should be set close to the wire feed speed of the

wire feeder in inches per minute. The Volts window

will have SPd displayed indicating Wire Feed

Speed. Once current starts flowing and during the 5

second

“

Hold

”

feature the displays will show amps

and volts.

Pulse Mode features that are displayed while selecting

a Welding pulse mode are listed below;

Steel - .030

”

, .035

”

, .045

”

, .052

”

, 1/16

” –

Argon Blends

Stainless Steel - .030

”

, .035

”

, .045

” –

Argon Blends &

Helium/Argon Blends

Aluminum - .035

”

, 3/64

”

, 1/16

” –

4043 & 5356

Metal Core - .045

”

, .052

”

, 1/16

” –

Argon Blends

Nickel - .035

”

, .045

” –

Argon/Helium blends

OUTPUT KNOB

REMOTE

REMOTE

ON

ON

REMOTE

REMOTE

LOCAL

LOCAL

WELD

WELD TERMINALS

TERMINALS

CONTR

CONTROL

OL

SELECT

SELECT

SELECT

SELECT

MPS

MPS

A

OL

OLTS

TS

V

ADVANCE PROCESS PANEL- MIDDLE SECTION OF WELDER (OPTIONAL)

MEMOR

MEMORY

MEMORY BUTTON

(M1 THRU M8)

SELECT BUTTON

(HOT START OR ARC CONTROL)

ADJUST KNOB

(0 THRU +10 HOT START)

(-10 THRU 0 AND 0 THRU +10 ARC CONTROL)

SELECT KNOB

(SCOLLS WELDING PROCESSES)

SELECT

SELECT

ADJUST

ADJUST

SELECT

SELECT

FIGURE B.2