2” f, Gas line installation, Figure 14 – LG B-VENT GAS GC3 User Manual

Page 11

11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Table

l

ower

f

ront

2” f

iller

p

anel

The FireStar™ insert comes with a 2” panel to fill the space be-

tween the insert bottom and the hearth extension. If the hearth

elevations necessitate, the insert may be installed directly on the

hearth without the leveling bolts or filler panel. To install the panel,

insert the four tabs on the top of the panel into the corresponding

slots in the insert bottom. Open the insert side doors, remove the

two socket head screws from the hardware bag and install them

(using a 5/32” hex wrench) through the insert bottom into the filler

panel. A tall adjustable filler panel is also available.

g

as

l

ine

i

nstallation

After leveling, position the insert in the fireplace, holding it about

six inches out from its final location.

Caution: Specific Hearth Requirements apply (see Clearances

and Specifications). The Firestar gas insert must be connected

to the gas line in accordance with local codes and / or the

National Fuel Gas Code, Z.1-latest edition, also known as

NFPA 54. Included in the manual package is an 8" gas nipple.

Locate the threaded gas inlet on the lower left of the insert.

Thread the 8" gas nipple into the inlet with a teflon sealer or

equivalent. Attach the gas supply line to this hard pipe. The

hard pipe can receive a /8” inch female iron pipe coupling, or a

shut off valve. After connecting the gas line, all joints in the line

and connections at the valve should be checked for leaks.

g

as

p

ressure

r

equirements

A MAJOR CAUSE OF OPERATING PROBLEMS WITH GAS

APPLIANCES IS IMPROPER GAS PRESSURE!

The most important item to check during the initial

installation and the first thing to check when operating

problems occur is gas pressure! This appliance will not

function properly unless the required gas pressure is

supplied. See Table 1 for gas pressure requirements.

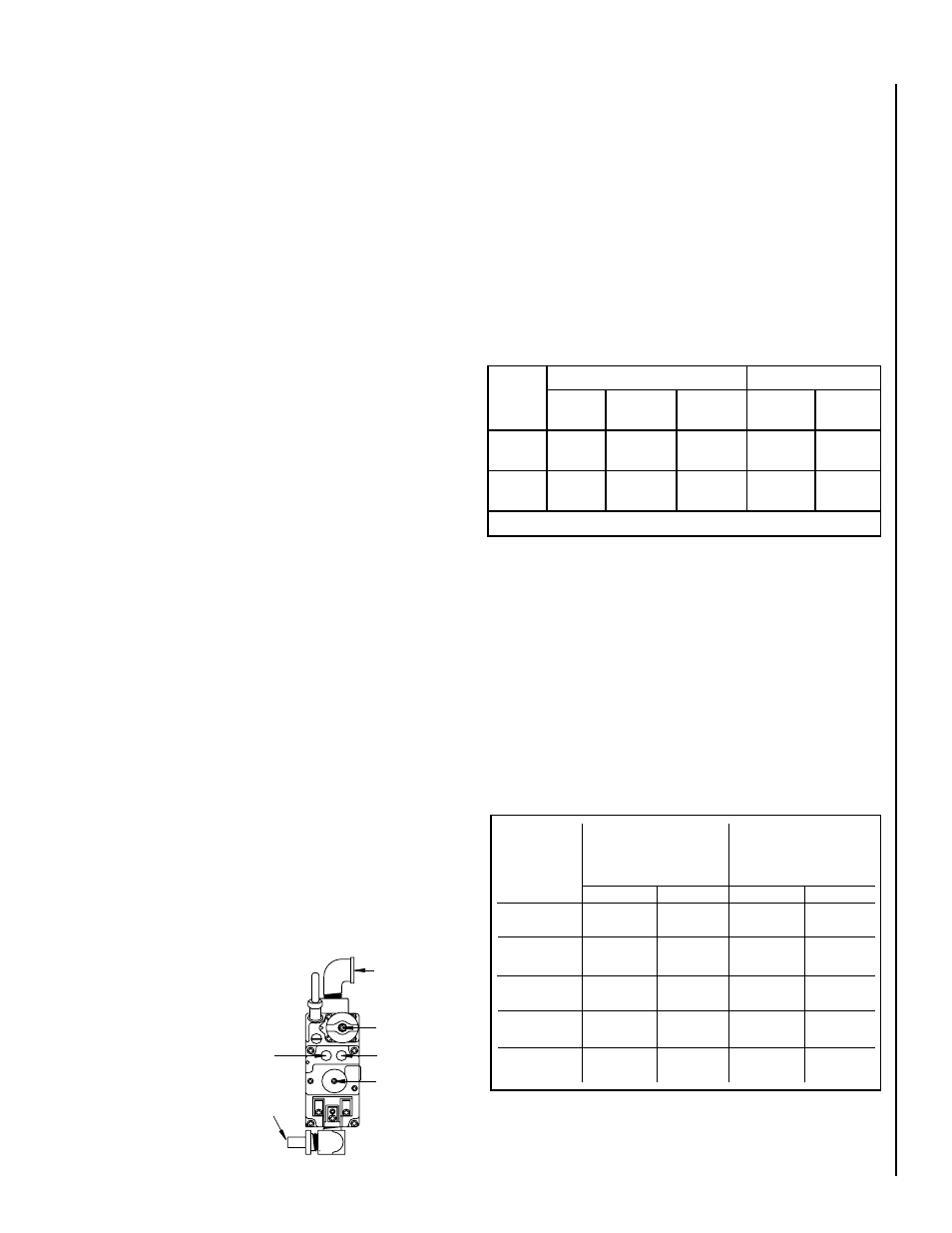

Two pressure taps are provided on the insert's valve to check

gas pressures. The taps are located below the on/off/pilot knob

(see Figure 14). The left tap is the inlet (supply) pressure side.

To check inlet pressure (with the insert burning), insert a small

phillips screwdriver into the tap and turn a half turn counter-

clockwise. Cover the tap with the line from a manometer and

check the pressure. Close tap gently but securely after completing

the check. The manifold (outlet) tap is to the right of the inlet tap.

To check manifold pressure (with the insert burning at the high

burn setting) insert a small

phillips screwdriver into

the tap and turn a half turn

counter-clockwise. Cover

the tap with the line from

the manometer and check

the pressure. Again close

the tap gently but securely

after completing the check.

Check the taps for gas leaks

with a gas leak test solution

(retighten if necessary).

g

as

s

upply

l

ine

s

izing

The proper gas line diameter must be selected to run from the

supply regulator to the insert. Refer to the Table 2 for proper gas

pipe diameters.

NOTE: Some areas allow copper tubing - check with local approval

agencies and codes.

COPPER TUBING NOT ALLOWED IN MASSACHUSETTS IN

NATURAL GAS INSTALLATIONS, NEVER USE GALVANIZED OR

PLASTIC PIPES.

Fuel

Type

Inlet Pressure

Manifold Pressure

Desired Minimum Maximum

On Hi

Fire

On Lo

Fire

Natural

Gas

7" WC

5" WC

10.5" WC

.5" WC

1.7" WC

LP Gas 11" WC 10.5" WC

1" WC

10.0" WC 5.4” WC

Table 1

12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

1

/

2

"

(1.3 cm)

7

/

8

"

(2.3 cm)

3

/

4

"

(2.0 cm)

3

/

4

"

(2.0 cm)

150-200

3

/

4

"

(2.0 cm)

100-150

1

/

2

"

(1.3 cm)

7

/

8

"

(2.3 cm)

3

/

4

"

(2.0 cm)

1

/

2

"

(1.3 cm)

3

/

4

"

(2.0 cm)

1

/

2

"

(1.3 cm)

1

/

2

"

(1.3 cm)

40-100

1

/

2

"

(1.3 cm)

5

/

8

"

(1.6 cm)

1

/

2

"

(1.3 cm)

10-40

3

/

8

"

(1.0 cm)

1

/

2

"

(1.3 cm)

3

/

8

"

(1.0 cm)

1

/

2

"

(1.3 cm)

0-10

Natural Gas

Natural Gas

L.P.

L.P.

Pipe Length

(Feet from Supply

Regulator)

(Do Not Use Copper in Massachusetts

with Natural Gas)

Tubing, Type L Outside Diam-

eter (Copper)

Schedule 40 Pipe

Inside Diameter

(Black Pipe)

1

/

2

"

(1.3 cm)

Gas Line Installation

After leveling, position the insert in the fireplace --- holding it

about six inches out from its final location.

Caution: Specific Hearth Requirements apply (see Clearances

and Specifications). The

Designer™

must be connected to the

gas line in accordance with local codes and / or the National Fuel

Gas Code---

Z223.1-latest edition, also known as NFPA 54

(In Canada, the current CAN/CSA B149.1 installation code)

.

Included in the manual package is a 8" gas nipple. Locate the

threaded gas inlet on the lower left of the insert. Thread the

8" gas nipple into the inlet with a teflon sealer or equiv. Attach

the gas supply line to this hard pipe. The hard pipe can receive

a 3/8” inch female iron pipe coupling, or a shut off valve. After

connecting the gas line, all joints in the line and connections

at the valve should be checked for leaks.

G

as

s

upply

l

ine

s

izinG

The proper gas line diameter must be selected to run from the

supply regulator to the stove. Refer to the following table for

proper gas pipe diameters.

NOTE: Some areas allow copper tubing - check with local approval

agencies and codes.

COPPER TUBING NOT ALLOWED IN MASSACHUSETTS IN

NATURAL GAS INSTALLATIONS, NEVER USE GALVANIZED OR

PLASTIC PIPES.

Figure 14

If the pressure is not sufficient, make sure the gas supply line

is large enough, the supply regulator is properly adjusted, and

the total gas load for the residence does not exceed the amount

supplied.

The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/ psig.

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/ psig. Check with your gas

supplier or plumber.

Inlet

Pressure

Tap

Inlet Elbow

Off/On/Pilot

Manifold

Pressure Tap

Flame Height

Adjustment

Outlet

Orifice