1 - pcb removal and replacement, Operate. refer to, Section 5.4.1, “pcb removal and – KVH Industries TracVision L2 User Manual

Page 47: Replacement, For details on the fuse location and, 1 pcb removal and replacement

5-5

Maintenance

54-0195 Rev. A

5.4.1 PCB Removal and Replacement

Estimated Time to Repair:

1

⁄

2

hour

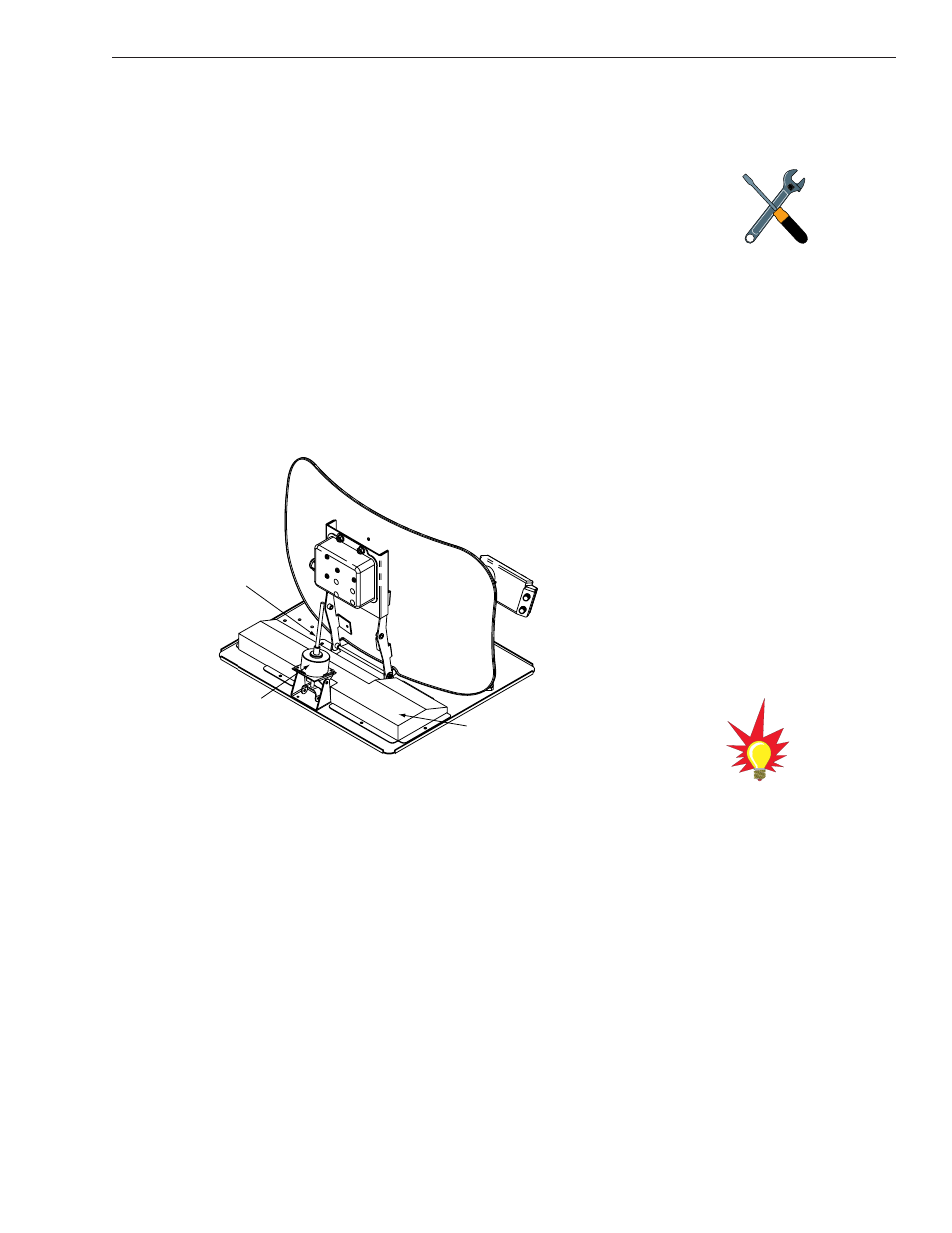

The microprocessor PCB assembly is protected by a cover

fastened to the rotating plate –

removed to gain access to the main power fuse and the PCB

assembly.

1. Using needle-nose pliers, remove the E-ring from

one end of the connecting rod –

2. Remove the connecting rod by sliding it off the

bracket.

3. Fully retract the elevation axis motor shaft

– Fig. 5-5.

4. Remove 6 pan head screws from the PCB cover

flanges.

5. Remove the PCB cover. To get the necessary

clearance, rotate the linear actuator up 90º while

lifting the PCB cover – Fig. 5-5.

6. Remove all cable connectors from the PCB.

Figure 5-6 on the following page illustrates the

PCB arrangement and connector locations.

TracVision L2 is equipped with a

5x20 mm, 3.15-amp, 250 volt fast-

blow fuse, which is mounted on the

PCB. To access and replace the

fuse, remove the PCB cover.

When carrying out maintenance

on the PCB, be sure to not drop

any of the small screws inside the

mechanism. If a screw is lost within

the baseplate, it must be retrieved

to avoid causing any damage when

the unit rotates.

PCB Cover

Linear Actuator

Elevation Axis

Motor Shaft

Figure 5-5

Removing the PCB Cover