Caution – Kobe Range Hoods IN2730SF User Manual

Page 7

5

- For Insert installation -

Preparation Before Installation

NOTE: TO AVOID DAMAGE TO YOUR HOOD, PREVENT

DEBRIS FROM ENTERING THE VENT OPENING.

•

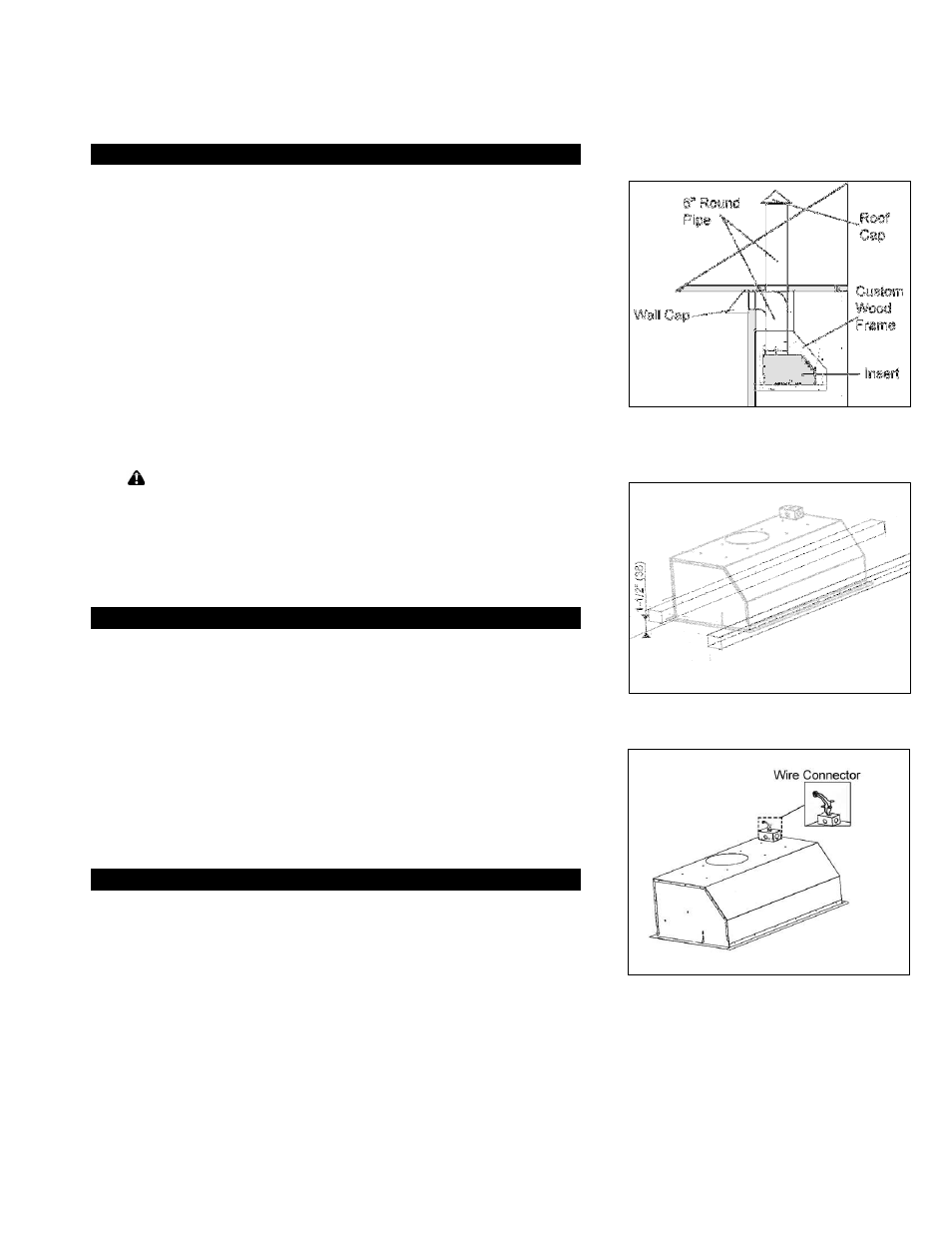

Decide the location of the venting pipe from the hood to

the outside. Refer to Figure 1.

•

A straight, short vent run will allow the hood to perform

more efficiently.

•

Try to avoid as many transitions, elbows, and long run

as possible. This may reduce the performance of the

hood.

•

Temporarily wire the hood to test for proper operation

before installing.

•

Important: Peel protective film off the hood, if any.

•

Use duct tape to seal joints between pipe sections.

CAUTION

: If moving the cooking range is

necessary to install the hood, turn off the power in an

electric range at the main electrical box. SHUT OFF

THE GAS BEFORE MOVING A GAS RANGE. And use a

protective

covering

to

protect

cooktop

and/or

countertop from damage.

Custom Hood Preparation

1. The custom hood frame must be sized to shape and the

weight of the insert. Refer to Measurements and

Diagrams on Page 11.

2. It must have a sturdy base (1/2 inch thick plywood

recommended) to sustain the weight of insert.

3. If an optional liner will be installed, the side of the wood

cabinet must be sturdy (1/2 inch thick plywood

recommended).

4. It is recommended to install a rear and front stud

support. Refer to Figure 2. The stud supports are

located 1-1/2” up from the base of the wood frame.

Liner Installation

5. The custom/wood hood must have a sturdy base to

accommodate the cut-out for the inset. The base must

be recessed to accommodate the height of the liner (See

liner dimension on Page 12)

6. Secure the liner to the bottom of the base using screws

(not included) appropriate for the size and material of

your wood frame.

7. Position the rear section of the liner so that it aligns with

the back edge of the custom wood frame. Use a pen to

trace the outline of the pre-cut area. Remove the liner

and proceed to Hood Preparation Before Installation on

Page 6.

8. Install the liner with 5 screws (not provided).

Figure 1

Figure 2

Figure 3