Kohler K582 User Manual

Page 11

11

Kohler Carburetor Adjustment

1. With the engine stopped, turn the low idle fuel

adjusting needle in (clockwise) until it bottoms

lightly.

NOTE: The tip of the idle fuel and main fuel

adjusting needles are tapered to critical

dimensions. Damage to the needles and

the seats in carburetor body will result if

the needles are forced.

2. Preliminary Settings: Turn the adjusting needles

out (counterclockwise) from lightly bottomed to

the positions shown in the chart.

Carburetor Troubleshooting

and Adjustments

NOTE: Carburetor adjustments should be made only

after the engine has warmed up.

Kohler K582 engines are equipped with Kohler

adjustable main jet carburetors.

The carburetor is designed to deliver the correct

fuel-to-air mixture to the engine under all operating

conditions. The main fuel and idle fuel needles on

adjustable jet carburetors are set at the factory and

normally do not require further adjustment.

Troubleshooting

If engine troubles are experienced that appear to be

fuel system related, check the following areas before

adjusting the carburetor.

Make sure the fuel tank is filled with clean, fresh

gasoline.

Make sure the fuel tank cap vent is not blocked

and that it is operating properly.

If the fuel tank is equipped with a shutoff valve,

make sure it is open.

If the engine is equipped with an in-line fuel filter,

make sure it is clean and unobstructed. Replace

the filter if necessary.

Make sure fuel is reaching the carburetor. This

includes checking the fuel lines and fuel pump for

restrictions or faulty components, replace as

necessary.

Make sure the air cleaner element is clean and all

air cleaner element components are fastened

securely.

If, after checking the items listed above, the engine is

hard to start, runs roughly, or stalls at low idle speed, it

may be necessary to adjust or service the carburetor.

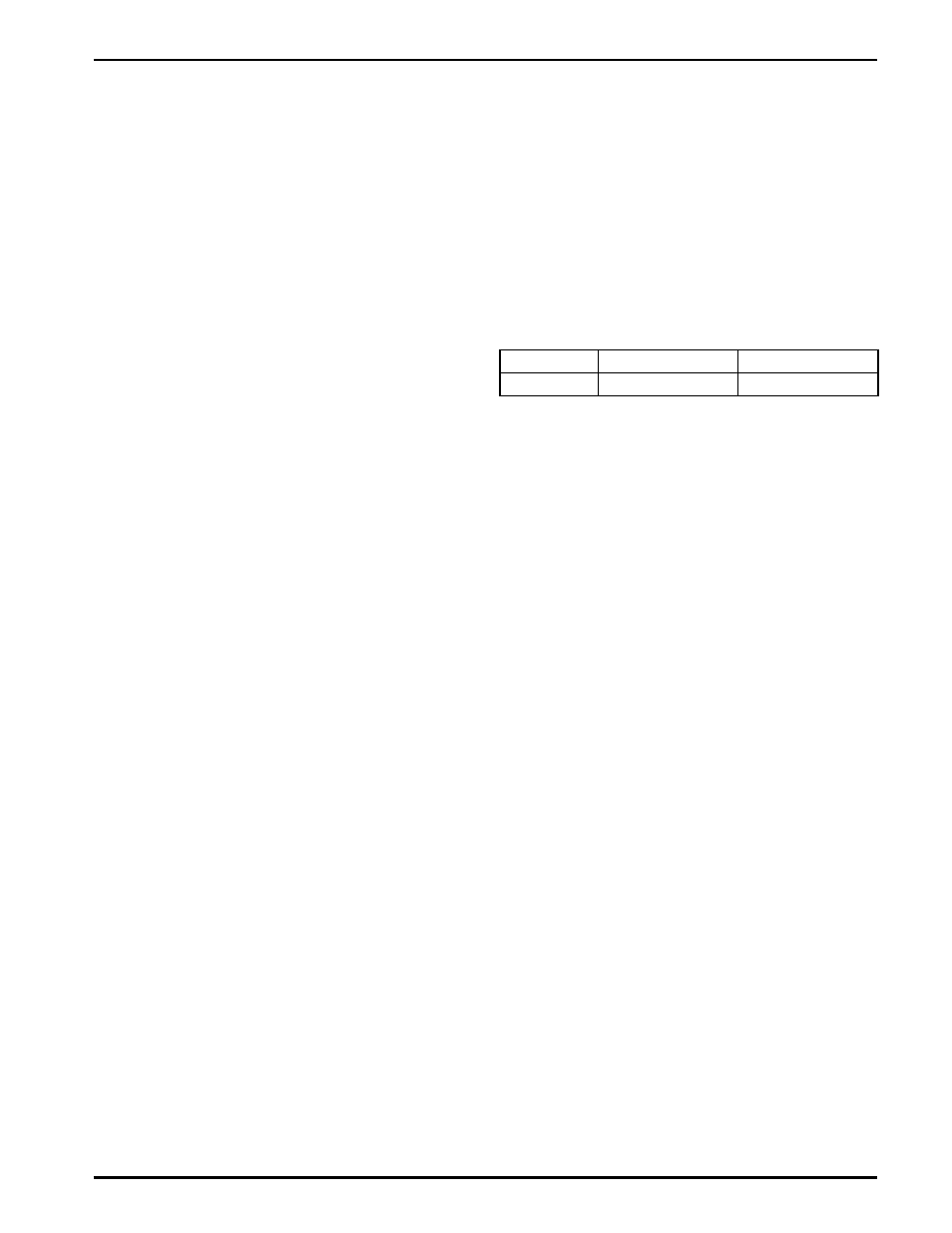

Low Idle

Main Fuel

K582

1-1/4 turns

3 turns

3. Start the engine and run at half throttle for 5 to 10

minutes to warm up. The engine must be warm

before making final settings.

4. Main Fuel Needle Setting: Place the throttle into

the "fast" position. If possible, place the engine

under load.

Turn the main fuel adjusting needle out

(counterclockwise) from the preliminary setting

until the engine speed decreases (rich). Note the

position of the needle.

Now turn the adjusting needle in (clockwise). The

engine speed may increase, then it will decrease

as the needle is turned in (lean). Note the position

of the needle.

Set the adjusting needle midway between the

rich and lean settings.

5. Low Idle Speed Setting: Place the throttle

control into the idle or slow position. Set the

low idle speed to 1200 RPM* (± 75 RPM) by

turning the low idle speed adjusting screw in or

out. Check the speed using a tachometer.

*NOTE: The actual low idle speed depends on

the application refer to equipment

manufacturer's recommendations. The

recommended low idle speed for basic

engines is 1200 RPM. To ensure best

results when setting the low idle fuel

needle, the low idle speed must not

exceed 1500 RPM.