Kodak E-6 User Manual

Visual troubleshooting of process e-6

Using KODAK Chemicals, Process E-6

•

Z-119 Sixth Edition

12-1

12

VISUAL TROUBLESHOOTING

OF PROCESS E-6

Once you have eliminated improper film storage and incorrect exposure as causes of poor-quality transparencies on KODAK

EKTACHROME Film, check for processing problems. These problems include errors in chemical mixing, order of processing

steps, processing temperature, agitation, washing, replenishment, and solution contamination.

A visual check of the processed film is one way to make an initial diagnosis. You can make a more thorough determination of

the cause of processing problems and the corrective action to take by plotting and evaluating your control-strip densities; see

section 13, “Process Monitoring.”

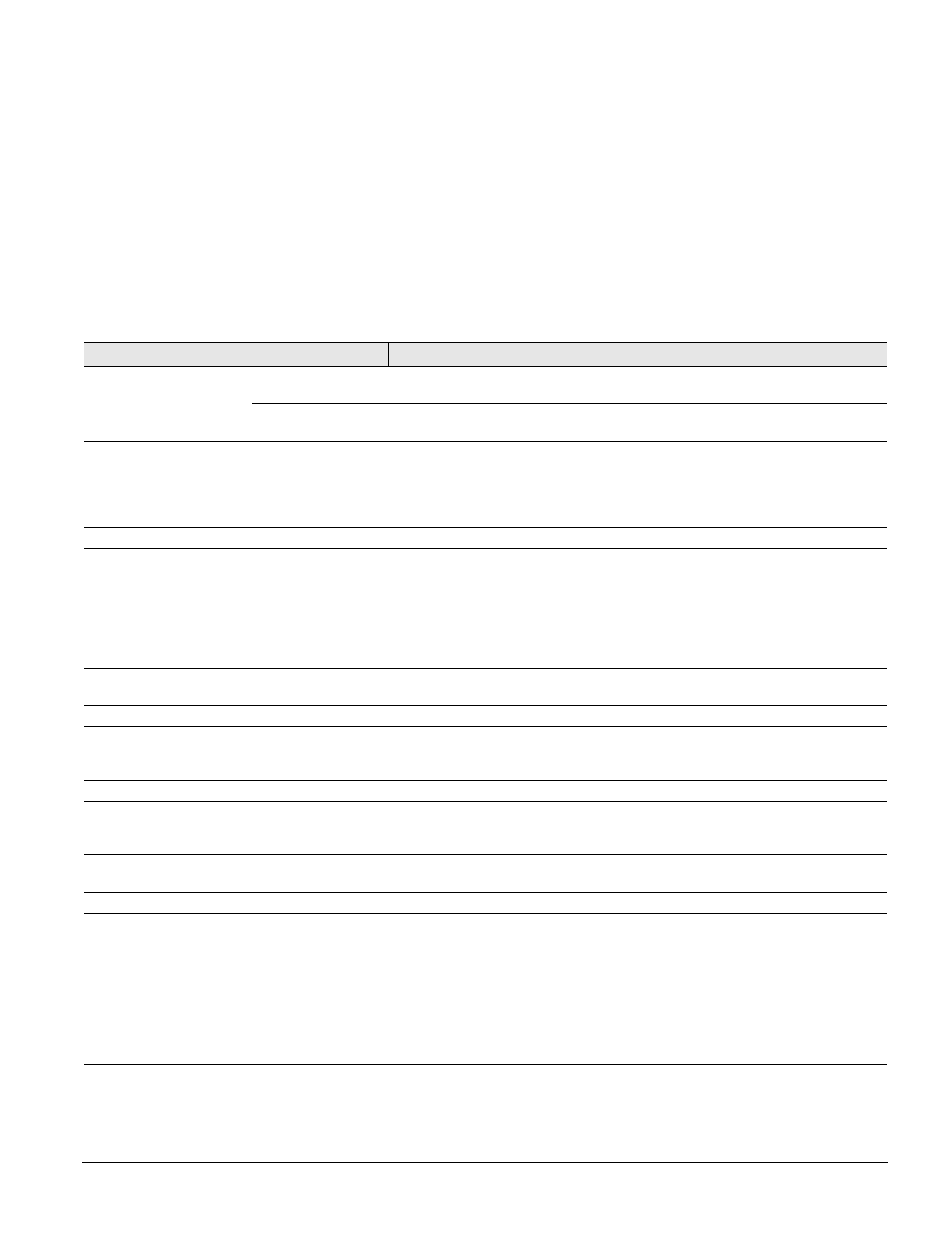

Table 12-1

Troubleshooting from the Appearance of Processed Film

Appearance of Film

Possible Cause

Very High Maximum

Density (very dark

no apparent image)

No Edgeprint

Visible

First developer omitted

Edgeprint

Visible

First developer and color developer reversed

Film not exposed

Dark Overall

Inadequate time or low temperature in first developer

First or color developer diluted or exhausted

Color developer starter added to first developer

Too much first developer starter used

First developer or first and color developers underreplenished

Very Dark (overall or in random areas)

Bleach or fixer (or both) omitted, reversed, diluted, exhausted, or underreplenished

LIght Overall

Too much time or high temperature in first developer

Film fogged by light before processing

First or color developer (or both) too concentrated

First or color developer (or both) overreplenished

First developer starter omitted

First developer contaminated with reversal bath or color developer

First developer contaminated with fixer

Image Very Faint or No Image

(film may show colored streaks)

First developer used twice or color developer omitted

Severe light fog

Overall Density Variation from Batch to Batch

Inconsistent first-developer time, temperature, agitation, or replenishment

Blue

First developer contaminated with fixer

Reversal bath overconcentrated

Too little first developer starter used

Cyan

First-wash temperature too low

Yellow

Color-developer starter added to first developer

Too much first developer starter used

Inadequate bleaching or fixing

Yellow-Red

First developer with color developer starter added

Underreplenishment of first developer or color developer

Low Density Blue; High Density Yellow

Color developer contaminated with fixer

Green

Reversal bath exhausted, diluted, or underreplenished

Film fogged by green safelight

Wash used between color developer and reversal bath

Color developer dilute

Color pH high

Too much Part A in color developer

Overreplenished color developer

A dilute color developer

Color developer mixed using first developer starter