Warning – Kirby Morgan 37 User Manual

Page 2

69

Kirby Morgan 37 & 57

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

seat. Thread the seat into the valve body.

4) Tighten the seat to 150 inch lbs. (17 Newton me-

ters) with a torque wrench while holding the body

in a soft jaw vice or wrench.

5) If the adapter has been removed, it must be cleaned

and wrapped with Teflon tape.

poppet and the poppet O-ring usually come out in

the seat being followed by the spring.

The only functional part remaining in the valve body

is a non-moving, pressed-in cage. The function of the

cage is to prevent the poppet O-ring from blowing out

of place during high flows. Do not remove the pressed

in cage. This can only be done at the factory.

3) Inspect the body interior for foreign matter of any

type and clean, if necessary. Clean in accordance with

the cleaning instructions in Chapter 6. If corrosion is

present, clean using the acidic solution as outlined

in Chapter 6.

4) Inspect the seat, wiper, O-ring, poppet O-ring and

poppet for wear, replace if necessary. Be sure each

part is clean and all components are lightly lubricated

with the appropriate lubricant. A repair kit is available

for replacement parts. (Part #525-330)

5) Be careful to wipe the poppet and poppet O-ring

thoroughly, removing nearly all silicone to prevent

foreign materials from sticking to these compo-

nents.

6) Replace the spring.

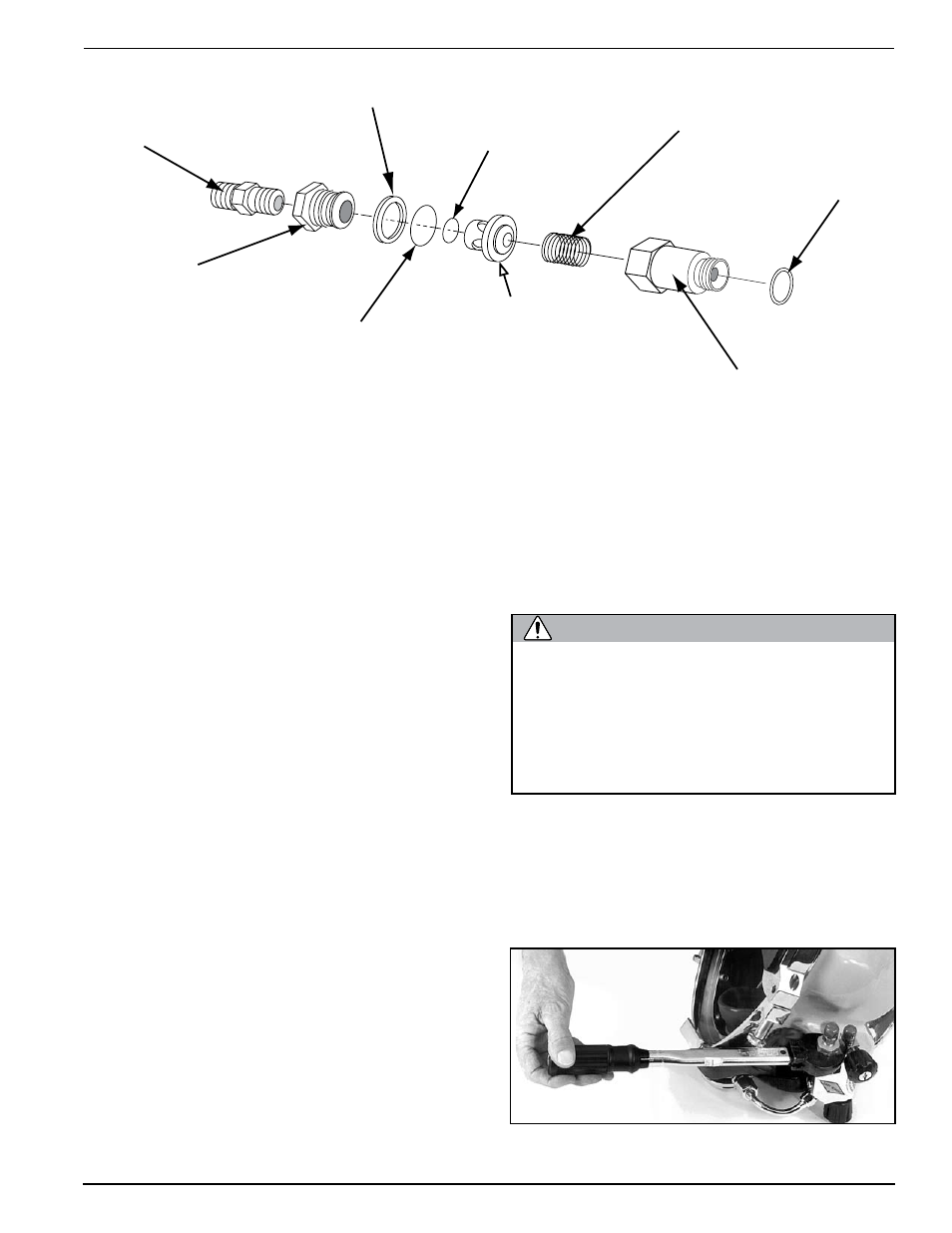

7.2.2 Reassembly of the One Way Valve

1) Slide the new O-ring over the poppet.

2) Insert the new spring into the valve body, followed

by the poppet.

3) Next, install the new O-ring and new wiper on the

Tighten to 150 inch lbs. (17 Newton Meters) with a

torque wrench.

Do not allow any Teflon tape to cover the

end of the adapter, or to enter the one-

way valve. Loose pieces of Teflon tape

can interfere with the performance of the

one-way valve or the regulator and may

block the diver’s air supply. This could

lead to death through suffocation.

WARNING

6) Test the operation of the valve.

7) Place the new O-ring on the end of the one way

valve assembly and reinstall the valve assembly in

the side block. Tighten to 150 inch lbs. (270 kg.cm.)

with a torque wrench.

Correct assembly order of the one way valve.

Adapter

Seat

Wiper

O-ring

O-ring

Poppet

Spring

Body

O-ring