Kirby Morgan 37 User Manual

Page 13

80

© Copyright 1970-2008 Kirby Morgan Dive Systems, Inc. All rights reserved. Document # 080508001

Kirby Morgan 37 & 57

7.7 SuperFlow 350

Demand Regulator

7.7.1 General Regulator Information

While the regulator systems on all Kirby Morgan hel-

mets are simple and highly reliable, the breathing re-

sistance will increase if the demand regulator on your

helmet is not maintained or adjusted properly. The

demand regulator must receive regular maintenance

to assure the best performance possible. However, in

the event the demand regulator is damaged, there is

always a backup supply of steady flow gas available

from the defogger valve.

If the regulator does not breathe easily, the diver can-

not work hard and will tire rapidly. Simply put: If the

demand regulator does not work properly the diver

cannot work properly. This makes the maintenance

of the demand regulator assembly essential.

For the gas inlet valve and adjustment system to oper-

ate properly, the components in the demand regulator

MUST be in good condition and MUST be periodi-

cally inspected and adjusted.

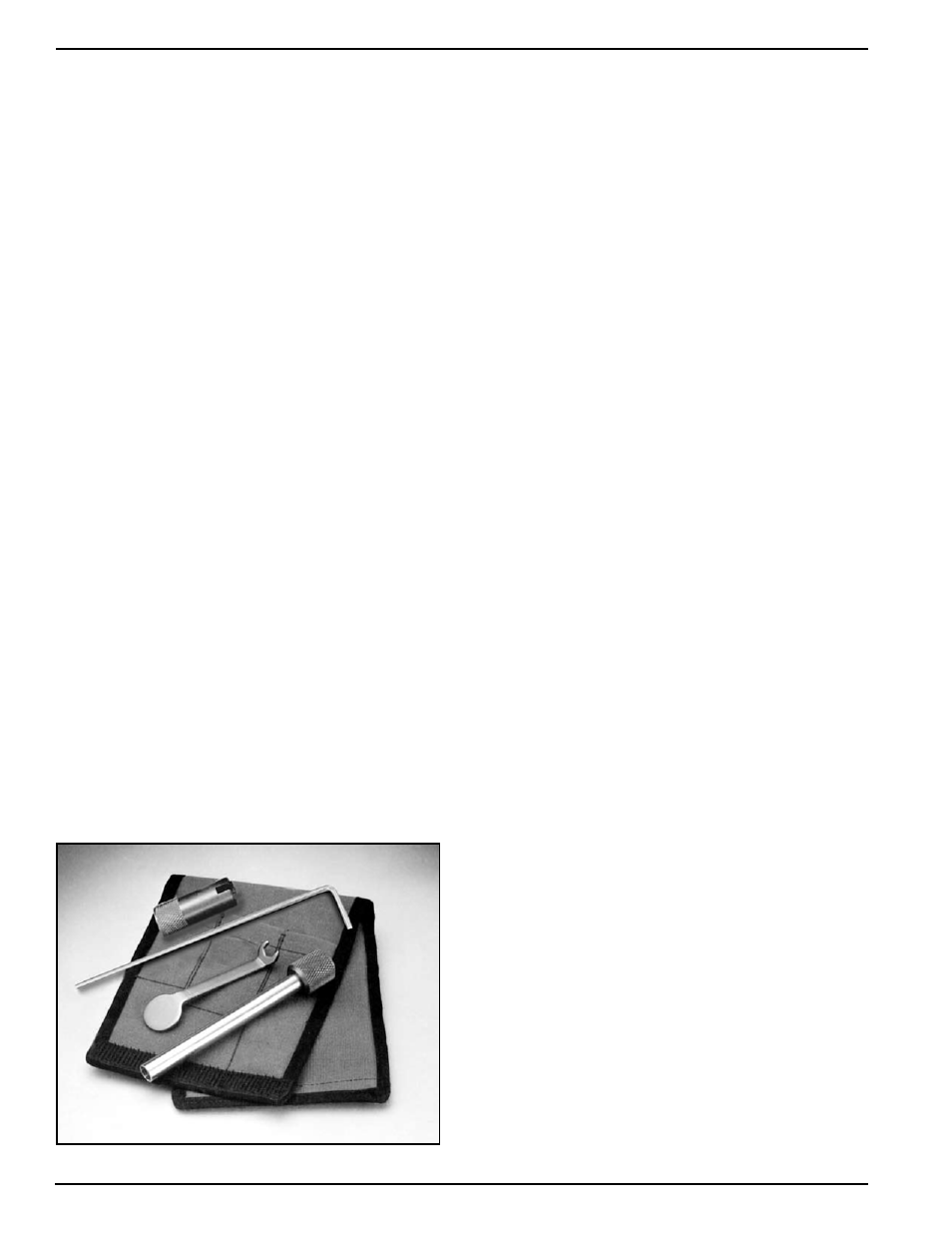

Four special tools, the inlet valve holder (Part #525-

616), the regulator adjustment wrench (Part #525-611),

the socket wrench (Part #525-612), and the castle

wrench (Part #525-618) should be used to work on

the SuperFlow 350 regulator whenever possible.

Disassembly, assembly, and adjustment can be done

without these tools, but the work is much easier and

the adjustment is better if these tools are used. The

above 4 tools are available together along with a tool

case. The “Tool Kit with Pouch” is Part #525-620.

This kit is included with each new Kirby Morgan

helmet that is equipped with the SuperFlow 350

regulator.

Tool Kit with pouch - Part #525-620.

7.7.2 SuperFlow 350 Demand Regulator Test

for Correct Adjustment, Fully Assembled

To maintain optimum performance of the demand

regulator, it should be checked for proper function

and adjustment prior to commencement of diving

each diving day, in accordance with the KMDSI Daily

Set Up and Functional Checklist. See the Dive Lab

website (www.divelab.com) for the latest procedures

for set-up.

Check the regulator for adjustment and proper func-

tion with the assembly complete, and supplied with a

breathing gas supply pressure of 135 to 150 p.s.i.g.

NOTE: 135 to 150 p.s.i.g. over ambient is the stan-

dard supply pressure to be used when adjusting

all KMDSI helmets and band-mask equipped with

the SuperFlow 350 regulator. See Section 2.5 for

recommended pressures during use.

NOTE: When storing the helmet for any length of

time, ensure that the regulator adjustment knob is

turned “out” fully counterclockwise to avoid stressing

the bias springs. This will prolong the life of both the

inlet valve, seat, and bias springs.

1) Rotate the regulator adjustment knob in, towards

the regulator body.

2) Ensure the supply pressure is connected and prop-

erly adjusted to 135 to 150 p.s.i.g.

3) Turn on the gas supply.

4) Rotate the adjustment knob out counterclockwise

slowly, until a slight steady flow develops.

5) Slowly rotate the adjustment knob in clockwise,

until the free flow stops. Lightly depress the purge

button several times and ensure the gas flow has

stopped.

6) Lightly depress the purge button. There should be

between 1/16” and 1/8” free travel in the button before

gas flow starts. When the button is fully depressed, a

strong surge of gas must be heard.

7) If the purge button travels less than 1/16” or greater

than 1/8” before free flow is heard, the demand regula-

tor requires internal adjustment, per this chapter.