Kawasaki 691225 User Manual

Page 7

Brushes will wear with use and should be inspected periodically by qualified

personnel.

Regularly clean the ventilation slots in your tool using only a soft brush or dry cloth.

Never open the Rotary Tool case. Do not attempt to repair the Rotary Tool yourself.

Opening the case will void your warranty.

A

AC

CC

CE

ES

SS

SO

OR

RIIE

ES

S

U

Usse

e o

on

nllyy a

acccce

esssso

orriie

ess tth

ha

att a

arre

e rre

ecco

om

mm

me

en

nd

de

ed

d b

byy tth

he

e m

ma

an

nu

uffa

accttu

urre

err ffo

orr yyo

ou

urr m

mo

od

de

ell..

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

A

Allw

wa

ayyss a

atttta

acch

h g

grro

ou

un

nd

de

ed

d ((3

3--p

prro

on

ng

g)) e

exxtte

en

nssiio

on

n cco

orrd

dss tto

o g

grro

ou

un

nd

de

ed

d ((3

3--h

ho

olle

e)) o

ou

uttlle

ettss..

T

Th

hiiss p

prro

od

du

ucctt ssh

ho

ou

ulld

d b

be

e g

grro

ou

un

nd

de

ed

d.. IIn

n tth

he

e e

evve

en

ntt o

off a

an

n e

elle

eccttrriicca

all ssh

ho

orrtt cciirrccu

uiitt,,

g

grro

ou

un

nd

diin

ng

g rre

ed

du

ucce

ess tth

he

e rriisskk o

off e

elle

eccttrriicc ssh

ho

occkk b

byy p

prro

ovviid

diin

ng

g a

an

n e

esscca

ap

pe

e w

wiirre

e ffo

orr tth

he

e

e

elle

eccttrriicc ccu

urrrre

en

ntt.. This product is equipped with a cord having a grounding wire with

an appropriate grounding plug. The plug must be plugged into an outlet that is prop-

erly installed and grounded in accordance with all local codes and ordinances.

IIff yyo

ou

u m

mu

usstt u

usse

e a

an

n e

exxtte

en

nssiio

on

n cco

orrd

d,, b

be

e ssu

urre

e tth

ha

att tth

he

e g

ga

au

ug

ge

e iiss lla

arrg

ge

e e

en

no

ou

ug

gh

h tto

o cca

arrrryy

tth

he

e a

am

mo

ou

un

ntt o

off ccu

urrrre

en

ntt n

ne

ecce

essssa

arryy ffo

orr yyo

ou

urr p

po

ow

we

err tto

oo

oll.. If not, your tool may

experience a loss of power, excessive voltage drop or overheating. The smaller the

gauge number, the heavier the cord (see table below).

R

RE

EC

CO

OM

MM

ME

EN

ND

DE

ED

D S

SIIZ

ZE

ES

S O

OF

F E

EX

XT

TE

EN

NS

SIIO

ON

N C

CO

OR

RD

DS

S 1

12

20

0 V

VO

OL

LT

T A

AC

C 6

60

0 H

HZ

Z T

TO

OO

OL

LS

S

T

TO

OO

OL

L C

CU

UR

RR

RE

EN

NT

T R

RA

AT

TIIN

NG

G

C

CO

ON

ND

DU

UC

CT

TO

OR

R S

SIIZ

ZE

E IIN

N A

A..W

W..G

G

AMPERE

10FT.

25FT.

50FT.

100FT.

3-6

18

18

18

18

6-8

18

18

18

16

8-10

18

18

18

14

10-12

16

16

14

14

12-16

14

12

12

-

16-20

12

12

12

-

12

If you are doing delicate woodcarving, polishing, buffing or any use which requires

a wire brush, slow speeds of 15,000 RPM or less are best. Any material, like plas-

tic, that melts at low temperatures should also be cut at low speeds.

If you are carving, routing, shaping or cutting glass, metal or hardwoods, higher

speeds are necessary. Drilling should also be done at high speed.

Softer metals, like aluminium, copper alloys, and tin may be cut at various speeds,

depending on the type of cutting being done. A lubricant like wax should be used on

the cutter to keep the cut material from adhering to the cutter teeth.

If the tool is not performing the way you think it should, perhaps you are using the

wrong accessory. Putting pressure on the tool will not help the performance.

M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E A

AN

ND

D C

CL

LE

EA

AN

NIIN

NG

G

A

Allw

wa

ayyss U

UN

NP

PL

LU

UG

G tth

he

e R

Ro

otta

arryy T

To

oo

oll ffrro

om

m tth

he

e p

po

ow

we

err sso

ou

urrcce

e

b

be

effo

orre

e iin

nssp

pe

eccttiin

ng

g,, p

pe

errffo

orrm

miin

ng

g a

an

nyy m

ma

aiin

ntte

en

na

an

ncce

e o

orr cclle

ea

an

niin

ng

g..

T

Th

hiiss R

Ro

otta

arryy T

To

oo

oll iiss llu

ub

brriicca

atte

ed

d b

be

effo

orre

e iitt lle

ea

avve

ess

tth

he

e ffa

acctto

orryy.. This lubrication should last for the life of the tool. No further

lubrication is required.

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get inside

the casing. Never immerse any part of the tool in a liquid. Always keep the ventila-

tion openings clear.

11

S

M

H

Slow

8,000-12,000 RPM

Medium

20,000-25,000 RPM

High

29,000-33,000 RPM

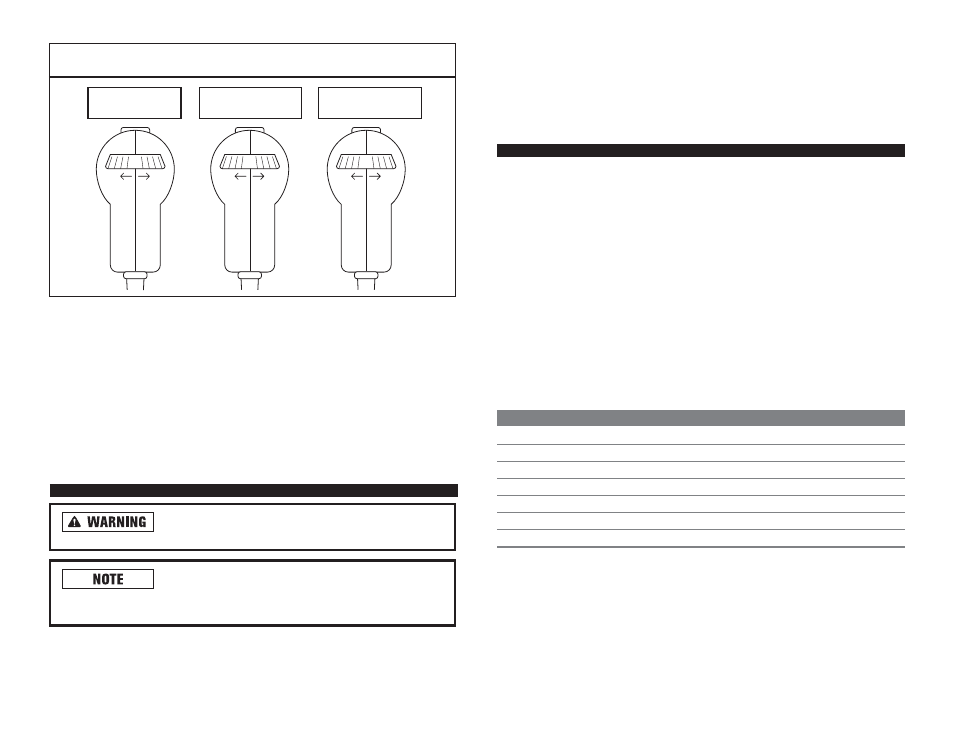

Rotary Tool Speed Settings