1 batteries – Kohler Generator Sets 20--2800 kW User Manual

Page 47

TP-5700 7/93

35

Section 7 Electrical Requirements

Section 7 Electrical Requirements

Before installing the generator set, provide for electrical

connections through conduit to the transfer switch and

other accessories for the generator set. Carefully install

the selected generator set accessories. Route wiring to

the generator set through flexible connections. Comply

with all applicable codes when installing a wiring

system.

AC circuit protection. All AC circuits must include

circuit breaker or fuse protection.

Select a circuit

breaker for up to 125% of the rated generator set output

current. The circuit breaker must open all ungrounded

connectors.

The circuit breaker or fuse must be

mounted within 7.6 m (25 feet) of the alternator output

terminals.

7.1 Batteries

Batteries should be located in a clean, dry area. Position

them so that the caps are readily accessible for checking

the electrolyte level. Keep batteries out of areas subject

to high temperatures. Locate them close to the set to

keep cables short and thus insure maximum output.

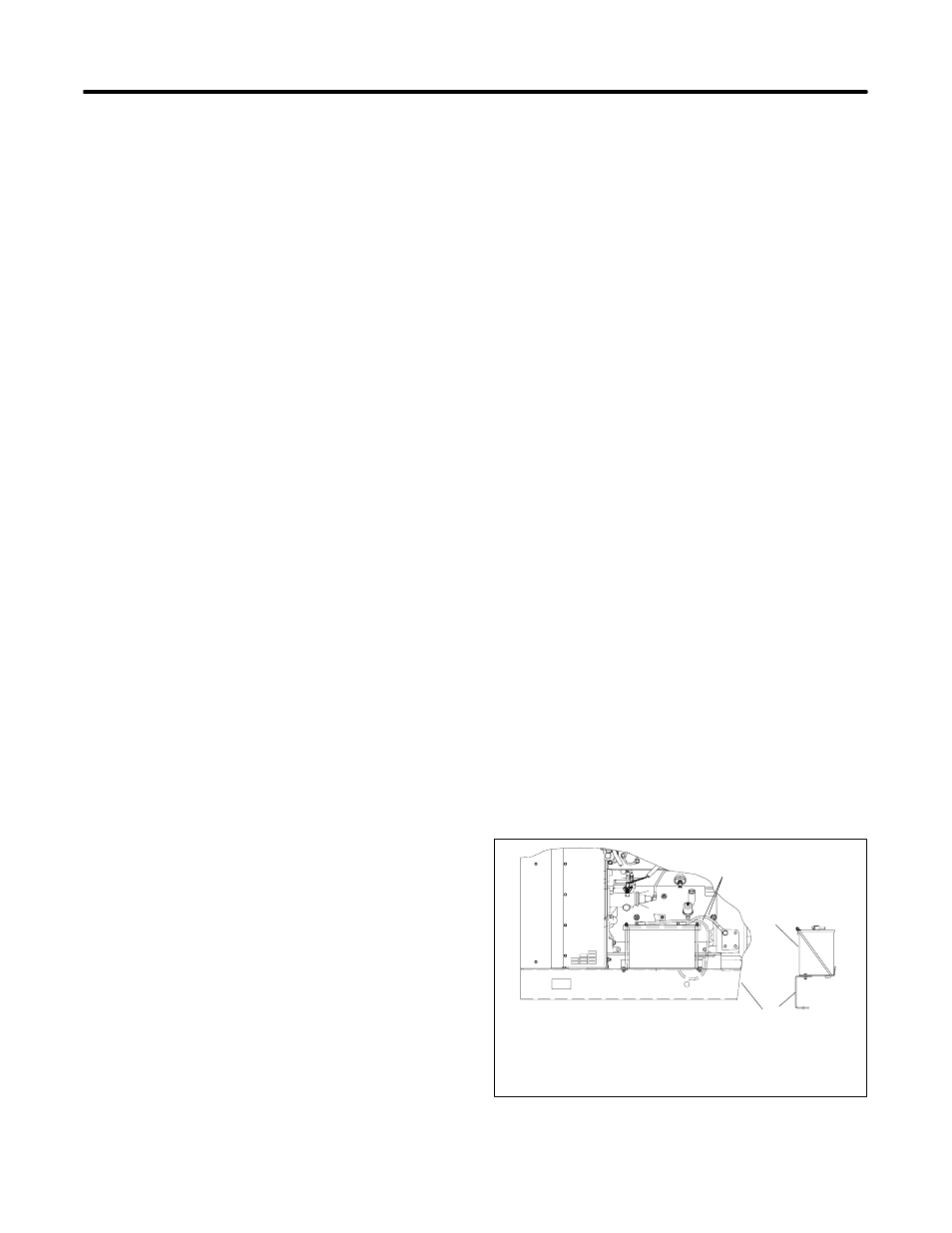

Several types of battery racks are used throughout the

product line—be sure to refer to the submittal drawings

for your unit. Figure 7-1 shows a typical battery system.

Starting batteries are usually lead-acid type sized

according

to

the

engine

manufacturer’s

recommendation for a particular ambient temperature

and required cranking time. Recommended cranking

periods are specified in NFPA 110. It allows a single

45-second cranking cycle for generator sets below

20 kW. For larger models, three 15-second crank cycles

separated by 15-second rests are required. The battery

industry rating standard most commonly used to specify

batteries is the cold-cranking ampere rating. Refer to the

unit’s specification sheet for battery cold-cranking

ampere rating.

Nickel cadmium batteries are sometimes used for

standby generator sets because of their long life

(20 years). This is offset by their high initial cost, larger

space

requirements,

and

special

charging

requirements. Conventional lead-acid batteries have

proven satisfactory for the majority of generator set

applications.

Batteries are charged by

engine-driven, battery

charging alternators whenever the generator set

operates. These systems are normally capable of

charge rates of 30 amperes or more and can restore the

charge used in a normal cranking cycle within a short

period of operation. When the engine is not operating, a

very low charge rate from an AC-powered battery

charger is sufficient to maintain the batteries fully

charged. These chargers may be automatic or manual

with a high charge rate of 2 amperes and a trickle charge

rate up to 300 milliamperes. They can be separate,

self-contained units or built into the automatic transfer

switch. Due to the low maximum charge rate, they are

not well suited to restoring fully discharged batteries.

Automatic float chargers with high charge rates of

10 amperes or more are available if full recovery

capability independent of the engine-driven charging

system is required.

The most common reason for the failure of an

emergency generator set to start when needed is

starting battery failure. Two common causes of battery

failure are: a manual charge rate set too low to maintain

the battery, or a manual chase rate set too high, which

results in loss of battery electrolyte. For this reason,

automatic float chargers, which vary the charge rate in

response

to

battery

condition,

are

strongly

recommended over manual types.

For large engines using two starters, either one bank of

batteries and chargers for both starters, or separate

battery systems may be used. The latter system is

preferable since it reduces the chance of one

component’s

failure

making

the

entire

system

inoperative.

Battery cables.

A UL-2200 listed generator set

requires battery cables with positive (+) lead boots.

Factory-supplied and optional battery cables include

positive (+) lead boots. When battery cables are not

factory-supplied, source battery cables with positive (+)

lead boots for UL-2200 compliance.

1

2

4

3

TP-5700-7

1. Battery cables

2. Battery secured in mounting rack

3. End view

4. Generator set skid

Figure 7-1

Typical Battery System, Side View