Kawasaki 840273 User Manual

Page 8

U

US

SIIN

NG

G T

TH

HE

E A

AN

NG

GL

LE

E G

GR

RIIN

ND

DE

ER

R::

FFo

orr b

beesstt tto

oo

oll cco

on

nttrro

oll,, m

maatteerriiaall rreem

mo

ovvaall aan

nd

d m

miin

niim

maall

llo

oaad

diin

ng

g,, kkeeeep

p tth

hee aan

ng

gllee b

beettw

weeeen

n tth

hee d

diisscc aan

nd

d tth

hee w

wo

orrkk ssu

urrffaaccee aatt aap

pp

prro

oxxii--

m

maatteellyy 3

30

0°° w

wh

heen

n g

grriin

nd

diin

ng

g aan

nd

d 1

10

0°°--1

15

5°° w

wh

heen

n ssaan

nd

diin

ng

g..

• Do not cover exhaust vents when the Angle Grinder is in use. This may cause

damage to the motor and reduce efficiency.

• Guide back and forth over the work piece in a steady motion.

• When cutting avoid tilting the Angle Grinder in the cutting plane. Ensure the cut-

ting wheel has a clean cutting edge.

• To cut hard stone a diamond cutting wheel is recommended.

• Do nut use cutting wheel for rough grinding.

M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E A

AN

ND

D C

CL

LE

EA

AN

NIIN

NG

G

A

Allw

waayyss U

UN

NP

PL

LU

UG

G tth

hee tto

oo

oll ffrro

om

m tth

hee p

po

ow

weerr sso

ou

urrccee b

beeffo

orree

cclleeaan

niin

ng

g o

orr m

maaiin

ntteen

naan

nccee..

• The armature and motor are the heart of the power tool. Exercise care to ensure

they do not become damaged or effected by oil or water.

• Inspect the carbon brushes regularly and replace them when they are worn.

(about 1/3 of the way up)

• Regularly inspect all mountings and screws and ensure they are properly tight-

ened. Failure to do so may result in serious damage.

• Consult an authorized maintenance service agent in event of damage.

• Clean and dust the Angle Grinder after each use.

• Use compressed air to blow out any accumulated dust or grit. Tiny

particles from metal grinding often accumulate inside your tool and could

create an electrical shock hazard.

• Never use solvents or harsh chemicals. Use only mild soap and a damp cloth to

clean the tool. Never let any liquid get inside the casing. Never immerse any

part of the tool in a liquid. Always keep the ventilation openings clear.

• Regularly clean the ventilation slots in your tool using a soft brush or dry cloth.

14

O

OP

PE

ER

RA

AT

TIIN

NG

G T

TH

HE

E O

ON

N//O

OFFFF S

SW

WIIT

TC

CH

H

N

Neevveerr ssw

wiittcch

h tth

hee A

An

ng

gllee G

Grriin

nd

deerr ““O

ON

N”” o

orr ““O

OFFFF”” w

wh

hiillee

u

un

nd

deerr llo

oaad

d cco

on

nd

diittiio

on

nss..

A

Allw

waayyss aallllo

ow

w tth

hee A

An

ng

gllee G

Grriin

nd

deerr tto

o cco

om

mee u

up

p tto

o ffu

ullll ssp

peeeed

d b

beeffo

orree tto

ou

ucch

hiin

ng

g aan

nyy

ssu

urrffaaccee..

A

Allw

waayyss ttaakkee tth

hee tto

oo

oll aaw

waayy ffrro

om

m tth

hee w

wo

orrkkp

piieeccee b

beeffo

orree ttu

urrn

niin

ng

g tth

hee tto

oo

oll ““O

OFFFF””..

Let the tool come to a complete stop before setting it down.

T

Th

hiiss tto

oo

oll o

op

peerraatteess b

beesstt u

un

nd

deerr lliig

gh

htt p

prreessssu

urree.. Exerting heavy pressure will not

speed up the work and may cause damage to the motor.

• When starting hold the Angle Grinder firmly with both hands. One hand on the

rear handle or the motor housing and the other hand on the side handle.

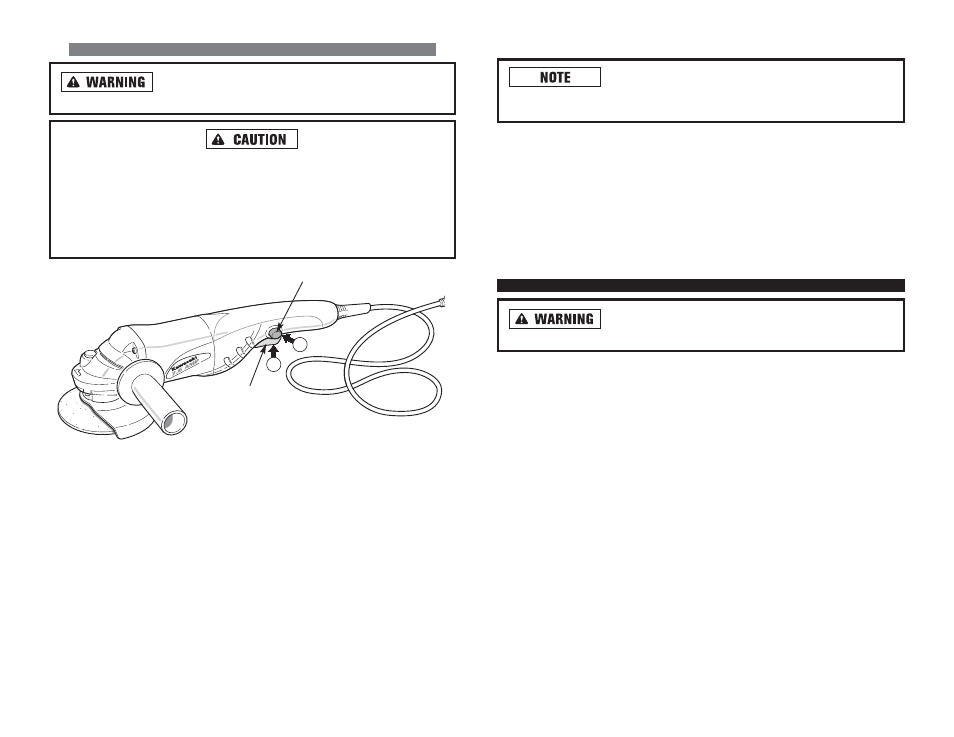

• The switch can be locked in the ““O

ON

N”” position, a convenience for long grinding

operations.

• To turn the Angle Grinder ““O

ON

N”” without locking it, apply pressure to the switch

button. When pressure is released, the switch button snaps to the ““O

OFFFF”” position.

• To lock th switch ““O

ON

N””, press the switch button forward and press the lock button.

• To unlock the switch, simply press and release the lock button. Switch is spring

loaded and will snap back automatically.

13

1

2

ON/OFF

SWITCH

LOCK-ON

BUTTON