Kawasaki Rotary Tool User Manual

Page 8

B

BA

AL

LA

AN

NC

CIIN

NG

G

For best results, be sure to balance each accessory in the collet. Your tool’s high

RPM makes imbalances easily detectable as a wobble while the tool is running. To

balance an accessory:

1. Stop the tool.

2. Loosen the collet nut.

3. Rotate the accessory 1/4 turn.

4. Tighten the collet.

5. Run the tool.

6. Continue adjusting as needed. You will hear and feel when the accessory is

properly balanced.

C

CO

ON

NN

NE

EC

CT

TIIN

NG

G F

FL

LE

EX

XIIB

BL

LE

E S

SH

HA

AF

FT

T T

TO

O T

TO

OO

OL

L

F

FO

OR

R M

MO

OD

DE

EL

LS

S 8

84

40

01

16

68

8 A

AN

ND

D 8

84

40

01

16

69

9::

N

Ne

evve

err b

be

en

nd

d tth

he

e fflle

exxiib

blle

e ssh

ha

afftt w

wiitth

h a

a rra

ad

diiu

uss o

off lle

essss tth

ha

an

n 6

6”

” w

wh

he

en

n o

op

pe

erra

attiin

ng

g..

Please store the flexible shaft in the designated compartment of the tool box

when not in use.

N

No

ott ffo

orr u

usse

e w

wiitth

h rro

ou

utte

err b

biittss.. Use with router bits with cause kickback.

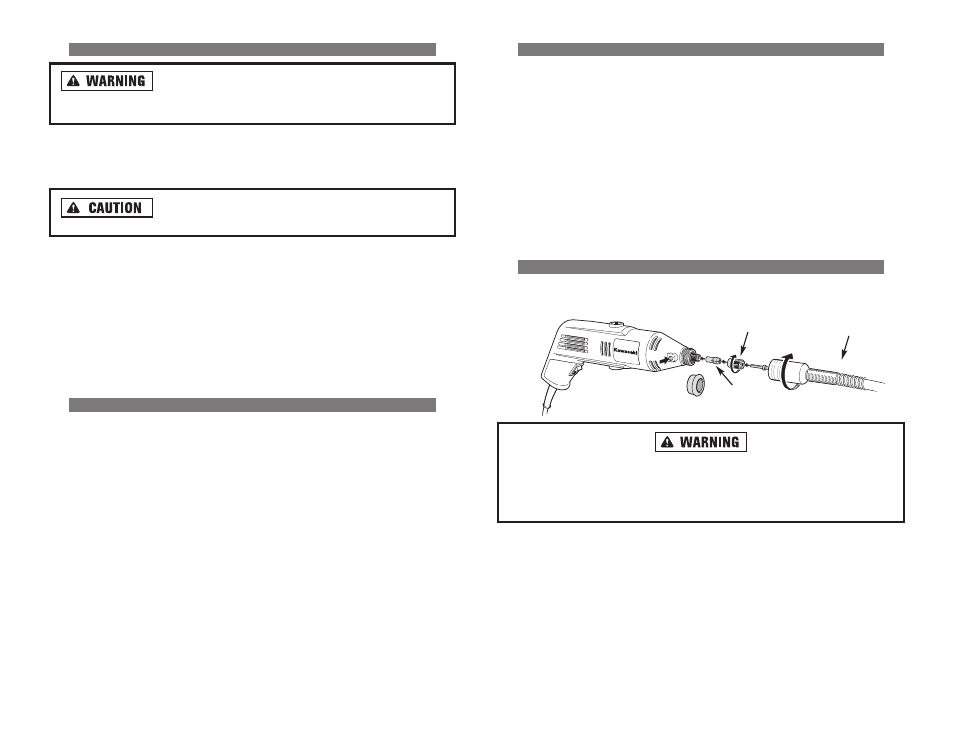

1. Remove spindle nut and collet nut from the tool by turning them counterclockwise.

2. Remove the collet from motor shaft.

3. Insert flexible shaft inner cable into the motor shaft until the stopper touches

the motor shaft.

4. Thread flexible shaft collet nut onto the motor shaft by turning it clockwise.

Tighten with collet wrench.

5. Thread flexible shaft nut onto the tool housing by turning it clockwise.

14

IIN

NS

SE

ER

RT

TIIN

NG

G//R

RE

EM

MO

OV

VIIN

NG

G A

AC

CC

CE

ES

SS

SO

OR

RIIE

ES

S

A

Allw

wa

ayyss u

un

np

pllu

ug

g rro

otta

arryy tto

oo

oll b

be

effo

orre

e cch

ha

an

ng

giin

ng

g a

acccce

esssso

orriie

ess,,

cch

ha

an

ng

giin

ng

g cco

olllle

ettss o

orr sse

errvviicciin

ng

g.. T

Th

he

e tto

oo

oll cco

ou

ulld

d sstta

arrtt u

un

ne

exxp

pe

ecctte

ed

dllyy,, cca

au

ussiin

ng

g

sse

erriio

ou

uss iin

njju

urryy..

T

TO

O L

LO

OO

OS

SE

EN

N T

TH

HE

E C

CO

OL

LL

LE

ET

T N

NU

UT

T::

1. Press the shaft lock button. Rotate the shaft manually until the lock engages

and prevents further rotation.

D

Do

o n

no

ott a

atttte

em

mp

ptt tto

o e

en

ng

ga

ag

ge

e tth

he

e ssh

ha

afftt llo

occkk w

wh

hiille

e tth

he

e tto

oo

oll iiss

rru

un

nn

niin

ng

g..

2. If the collet nut has a hexagonal shape, use a wrench to loosen the collet nut by

turning in the direction of the arrow labeled L in the illustration. The collet nut

must be loose in order to insert or remove accessories.

3. Remove the old accessory (if any) and install the new accessory, being sure to

push it as far as possible into the collet.

4. Tighten the collet nut by hand until snug.

5. Finish tightening the collet by turning the wrench in the direction of the arrow

labeled T in the illustration. Do not overtighten.

C

CO

OL

LL

LE

ET

T S

SIIZ

ZE

ES

S

Your rotary tool kit may have multiple collets to accommodate different accessories

with varying shank sizes.

T

TO

O C

CH

HA

AN

NG

GE

E A

A C

CO

OL

LL

LE

ET

T::

1. Loosen the collet nut as described above, then remove the collet nut.

2. Remove the old collet.

3. Insert the loose collet.

4. Tighten the collet nut as described above.

Each collet has a series of rings on its shank that identify its size.

• 1/32” – one (1) ring

• 1/16” – two (2) rings

• 3/32” – three (3) rings

• 1/8” – no rings

13

COLLET

COLLET NUT

FLEXIBLE

SHAFT