Maintenance – Shindaiwa H4 TRIMMER T344 User Manual

Page 14

14

Maintenance

WARNING!

Before performing any main-

tenance, repair, or cleaning work on

the unit, make sure the engine and

cutting attachment are completely

stopped. Disconnect the spark plug

wire before performing service or

maintenance.

WARNING!

Non-standard accessories, cut-

ting attachment, or replacement parts

may not operate properly with your unit

and may cause damage and lead to

personal injury.

IMPORTANT!

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED

BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A

DEALER OR SERVICE CENTER AUTHORIZED BY ECHO,INC. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN PER-

FORMANCE AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CON-

TROL SYSTEM AND MAY HAVE A BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

General maintenance

NOTE:

Using non-standard replacement parts could invalidate your Shindaiwa warranty.

Muffler

This unit must never be operated with a faulty or miss-

ing spark arrester or muffler. Make sure the muffler is well

secured and in good condition. A worn or damaged muffler

is a fire hazard and may also cause hearing loss.

Spark Plug

Keep the spark plug and wire connections tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except carburetor

adjusting screws) are tight.

Air Filter

The H4 engine that powers your Shindaiwa model is a hybrid

4-stroke engine. As a hybrid, the engine is lubricated by oil

mixed with the gasoline and air from the carburetor that moves

through and around the internal parts of the engine in a similar

way that a 2-stroke engine is lubricated. Without the heavy duty

2-stage air filter equipped on all H4 engines, dust and dirt could

also move through the engine, decreasing engine life, increas-

ing valve wear and the need for more frequent valve adjust-

ments. To keep your H4 engine strong and reliable, Shindaiwa

recommends that you check and service the air filter as

instructed in the 10-Hour Maintenance section that follows.

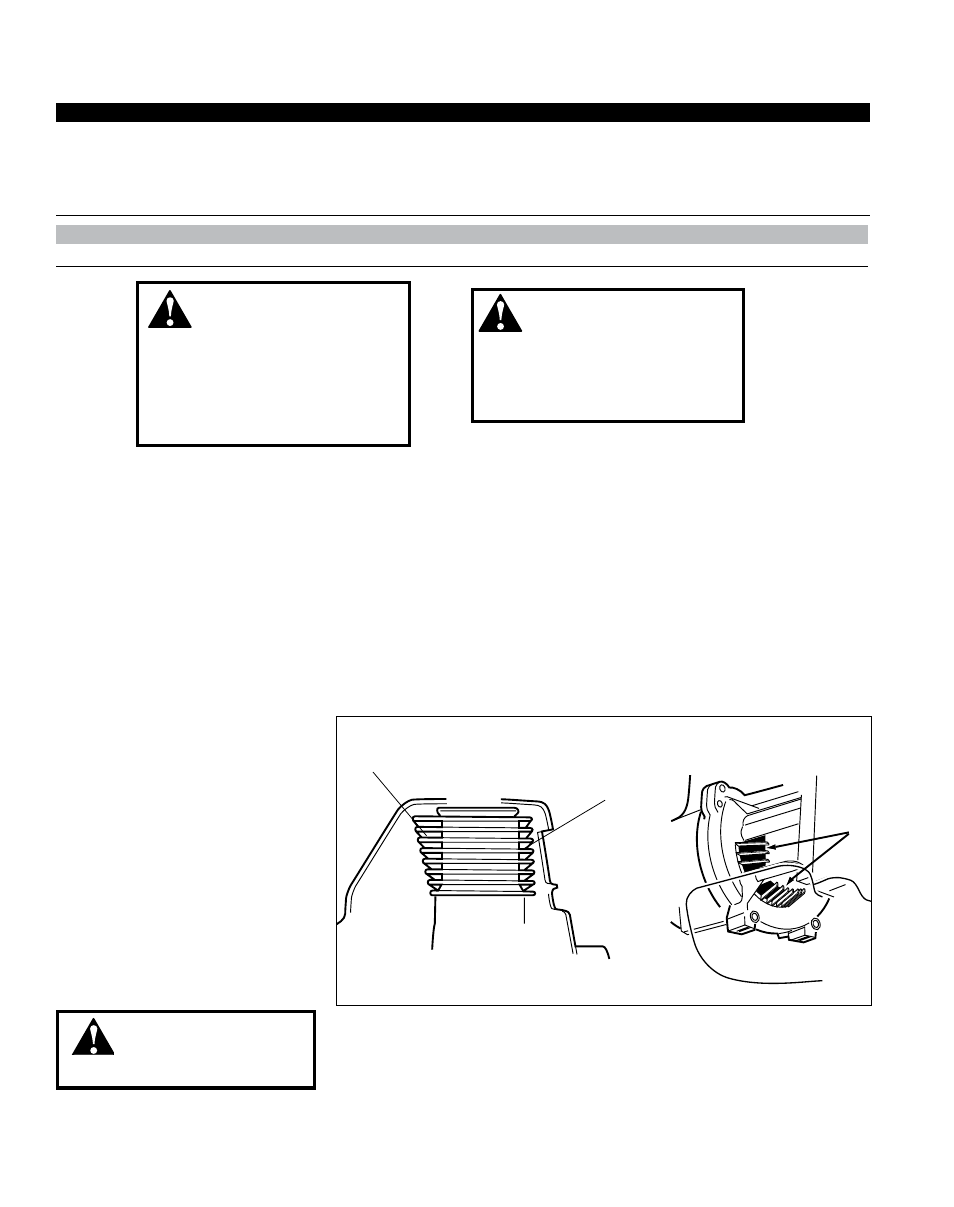

Prior to each work day, perform the

following:

■

Remove all dirt and debris from the

engine, check the cooling fins and

air cleaner for clogging, and clean

as necessary.

■

Carefully remove any accumula-

tions of dirt or debris from the muf-

fler and fuel tank. Check cooling air

intake area at base of crankcase.

Remove all debris. Dirt build-up

in these areas can lead to engine

overheating, fire, or premature

wear.

Daily maintenance

Remove all dirt and debris from the engine and check the cooling fins

Cooling

fins

Air

intake

Cooling

fins

WARNING!

Always wear gloves when

working around the cutter assembly.

■

Clean any debris or dirt from the cut-

ting attachment.

■

Check for loose or missing screws

or components. Make sure the cutter

attachment is securely fastened.

■

Check the entire unit for leaking

fuel or grease.

■

Make sure nuts, bolts, and screws

(except carburetor idle speed

adjusting screws) are tight.