Assembly, Emission control (exhaust & evaporative) – Shindaiwa LE254 User Manual

Page 6

6

Assembly

Prior to assembly

Before assembling, make sure you have

all the components required for a com-

plete unit. Carefully inspect all compo-

nents for damage.

IMPORTANT!

The terms “left”, “left-hand”, and

“LH”; “right”, “right-hand”, and “RH”;

“front” and “rear” refer to directions as

viewed by the operator during normal

operation.

■

Unit Assembly

■

Operator’s Manual

■

Assembly Tool (s)

■

Emission Control Warranty

Statement

■

Safety Glasses

Carefully inspect all components for

damage

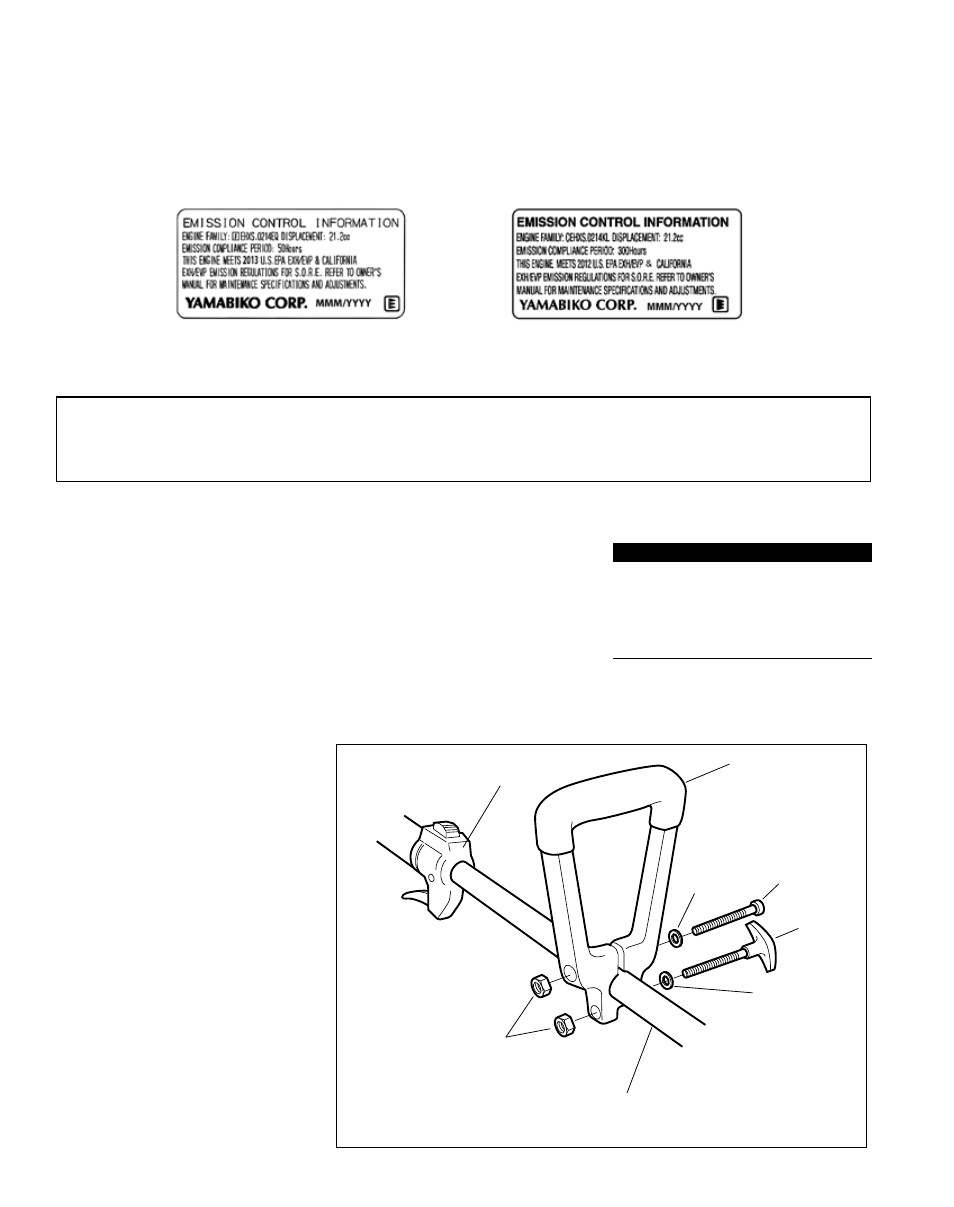

Adjustable Handle

This unit comes with the handle

installed. It can be re-adjusted for

operator comfort in the following

manner.

1. Loosen adjustment knob. Locate

the handle at the best position for

operator comfort (usually about

10 inches ahead of the throttle

lever), and secure it by tightening

the adjustment knob at the handle

base.

Handle

Hex Nut

Washer

Outer Tube

Adjustment Knob

Mounting Screw

Throttle Assembly

Washer

An Emission Control Label is located on the engine. (This is an EXAMPLE ONLY, information on label varies by engine

FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 50 or 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine

emissions output meets applicable emissions regulations, provided that approved maintenance procedures are fol-

lowed as listed in the Maintenance Section of this manual.

Emission Control (Exhaust & Evaporative)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM (engine modification) and, if the second to last character of the Engine

Family on the Emission Control Information label (sample below) is “C”, “K”, or “T”, the emission control system is EM and

TWC (3-way catalyst). The fuel tank/fuel line emission control system is EVAP (evaporative emissions). Evaporative emis-

sions for California models are only applicable to fuel tanks.