Service, Speed selector pivot adjust- ment, Traction drive clutch rod adjustment – Simplicity 1693426 755E User Manual

Page 20

16

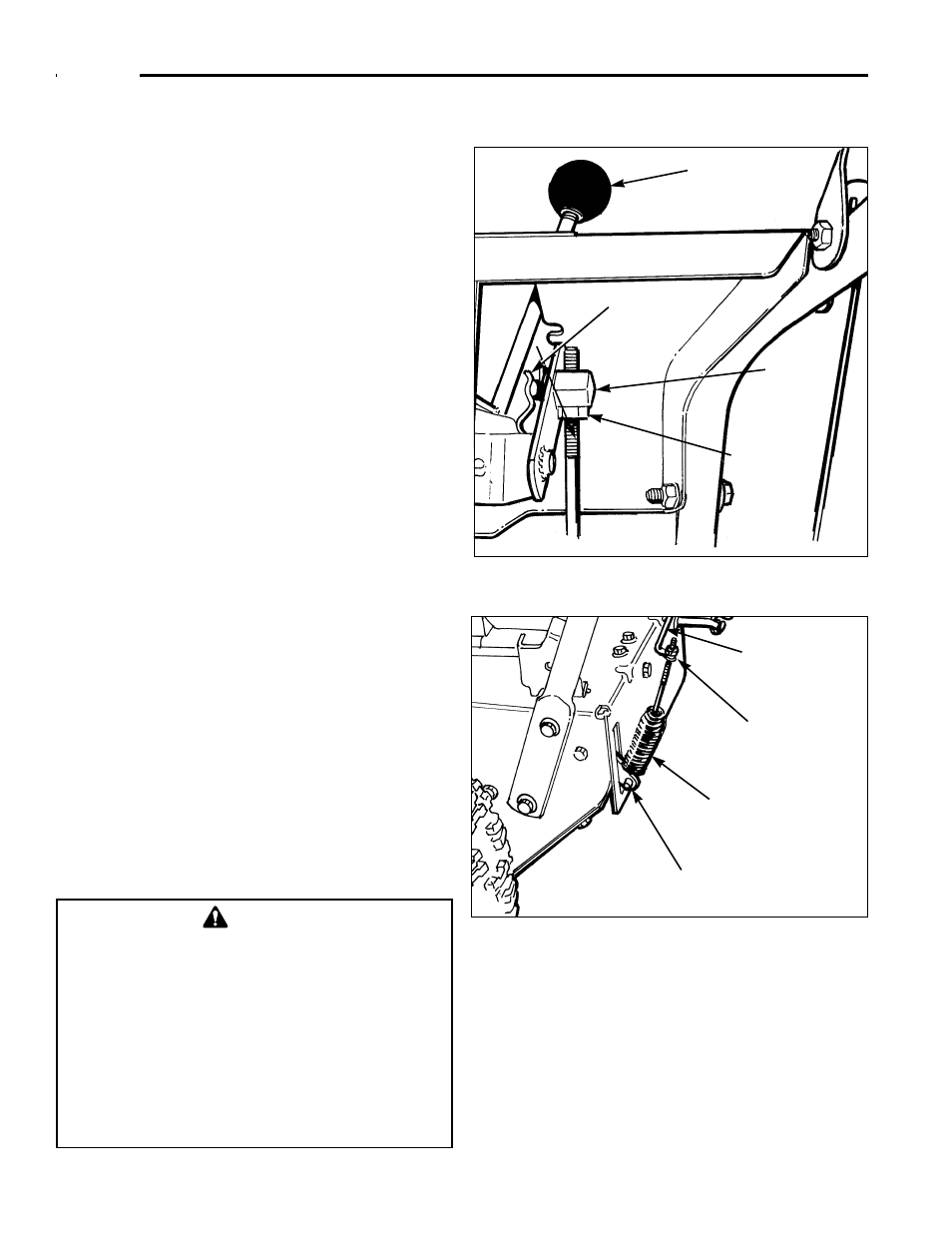

SPEED SELECTOR PIVOT ADJUST-

MENT

The Speed Selector is factory set for optimal perfor-

mance at each forward and reverse speed setting.

However, if speed position 1 is too slow, the speed can

be increased by changing the pivot position one turn. Do

not turn pivot more than one turn - increasing forward

speed using this method reduces reverse speed by a like

amount, and inadequate reverse speeds will result.

Adjust as follows:

1. Loosen pivot jam nut to permit pivot adjustment

(Figure 17).

2. Pull hitch clip pin out of pivot and remove washer.

3. Looking at end of threaded Speed Selector shaft, turn

pivot one turn counter-clockwise.

4. Reassemble pivot to control arm and secure with

washer and hitch clip pin.

5. Tighten jam nut.

6. Check speed position 1 for adequate speed. If unit

still moves too slowly, return pivot to original position

and use speed position 2 as a starting speed in place

Figure 17. Speed Selector Pivot Adjustment

Service

Hitch Clip Pin

Pivot

Jam Nut

Speed

Selector

TRACTION DRIVE CLUTCH ROD

ADJUSTMENT

Initial Adjustment

The traction drive clutch rod should initially be adjusted

so that there is no slack in the rod when moved slightly

from side to side, but bellcrank arm remains in fully down

position. To adjust tension on the rod:

1. Loosen adjustment hex nuts (Figure 18).

2. Tighten top hex nut while holding rod. Tighten just

until slack in rod is removed.

3. Tighten lower hex nut securely.

Figure 18. Traction Drive Clutch Rod Adjustment

Traction Drive

Clutch Rod

Traction Drive

Clutch Rod Spring

Adjustment

Hex Nuts

Traction Drive

Bellcrank Arm

Run-In Adjustment

1. After 5 hours of use, check for proper adjustment.

Readjust clutch rod if necessary by increasing ten-

sion on rod. A small amount of bellcrank arm move-

ment is permissible if unit passes operating checks

described in the Caution at left. Optimal adjustment

provides 1/32" clearance between traction drive

disc and rubber ring on friction disc when drive

lever is released (see Figure 14).

CAUTION

Do not over-tighten, as this may cause traction drive

to engage without depressing the traction Drive

Control (bellcrank arm must remain in down position).

Verify that the rods are not overtightened: With Speed

Selector in position 1 and traction Drive Control fully

released, push snowthrower forward. The unit should

move forward freely.

If unit does not move forward freely, the rod has

been over-tightened. To remedy, loosen tension on

clutch rod slightly, and recheck.