Maintenance (continued) – Shindaiwa EB802 User Manual

Page 14

14

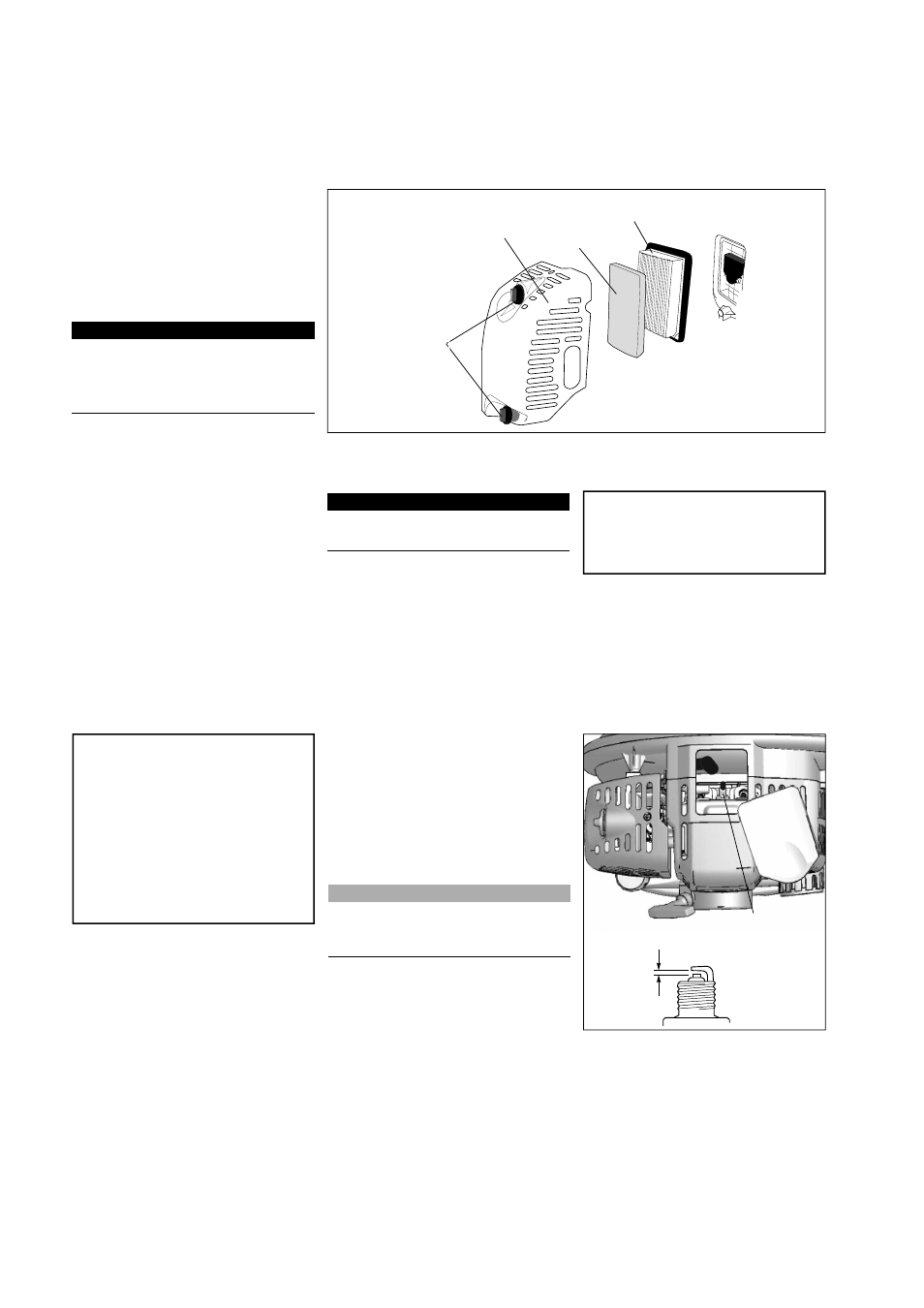

6. Install the fi lter element, pre-fi lter

and cover in the reverse order of

removal.

To remove the cover, loosen the

thumbscrews and lift.

Air Cleaner

Element

Cover

Figure 18

Pre-Filter

Thumbscrews

Every 10 Hours

(more frequently in dusty conditions)

CAUTION!

Never operate the blower if the air

cleaner assembly is damaged or

missing!

IMPORTANT!

Direct the air stream at the inside face

of the fi lter only!

1. Remove the air cleaner cover by

loosening the thumbscrews and lift-

ing. See Figure 18.

2. Remove and inspect the pre-fi lter.

If the pre-fi lter is torn or otherwise

damaged, replace it with a new one.

3. Clean the pre-fi lter with soap and

water. Let dry before reinstalling.

4. Inspect the air cleaner element. If

the element is damaged or distorted,

replace it with a new one.

5. Tap fi lter gently on a hard surface to

dislodge debris from element or use

compressed air from the inside to

blow debris out and away from the air

fi lter element.

IMPORTANT!

The blower uses a special high capac-

ity dry-type air fi lter element. The fi lter

should not be cleaned with a liquid

cleaner and must NEVER be oiled!

Counter-clockwise

to remove.

Clean the spark

plug and check

the gap at the

electrode.

0.6 mm

(0.024 in.)

Figure 19

Every 10/15 Hours

CAUTION!

Never allow dirt or debris to enter

the cylinder bore! Before removing

the spark plug, thoroughly clean the

spark plug and cylinder head area!

Allow the engine to cool before

servicing the spark plug! Cylinder

threads can be damaged by tighten-

ing or loosening the spark plug while

the engine is hot!

1. Use the spark plug wrench to

remove the spark plug.

2. Clean and adjust the spark plug gap

to 0.6mm (0.024 in.).

3. Install the spark plug fi nger-tight in

the cylinder head, then tighten it

fi rmly with the spark plug wrench.

■

Replace the spark plug annually:

Use only

NGK BPMR8Y

or equiva-

lent resistor type spark plug of the

correct heat range. Set spark plug

electrode gap to 0.6 mm (0.024 in.)

.

NOTE:

The NGK BPMR8Y also meets the require-

ments for electro-magnetic compliance

(EMC).

Maintenance (continued)