Names and functions of individual parts – Sierra Monitor Corporation PF5M User Manual

Page 5

7

6

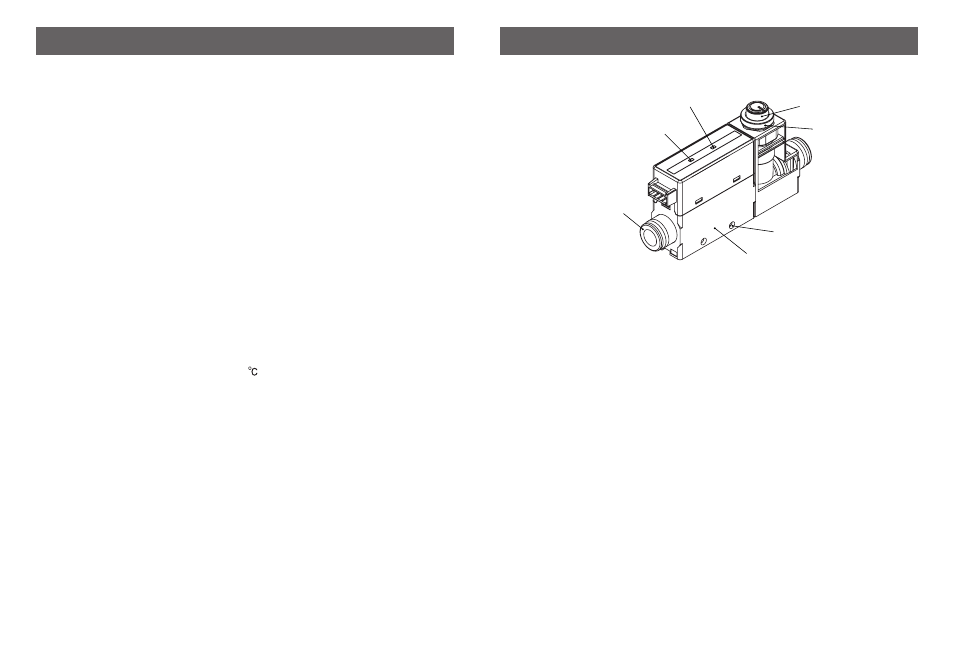

Names and Functions of Individual Parts

Power source display (green) : Turns on when power is supplied.

Flow display (green) : Flashing interval depends on the flow value.

As flow increases, flash interval is shortened.

The light turns to red when rated flow is exceeded.

Body : Flow sensor itself.

Flow adjustment valve : Orifice mechanism to abjust the flow.

Piping port : Connect port of piping.

Knurl : Used to fix the needle.

Through hole : Used to mount the flow sensor on a DIN rail or a panel directly.

IN

Power source display

Flow display

Flow adjustment valve

Knurl

Piping port

Body

Through hole

Safety Instructions (continued)

NOTE

• Wire as short as possible to avoid the affect of noise and surge.

• Never use in the presence of explosive gases.

• Do not use in an area where magnetic field is generated to avoid

malfunction of sensor.

• Do not operate where the flow sensor is exposed to water.

• Do not use in an area containing oil or chemicals.

• Do not apply heat cycle to the flow sensor.

• Do not used in an area where surges are generated.

• Sensors are not equipped with surge protection against lightening.

• Do not use load generate surge voltage.

• Avoid foreign material such as wiring chips in the product.

• Avoid using sensors in an environment where the likelihood of

splashing or spraying of water, chemicals, and oil to avoid failure and

malfunction.

• Consider operating environment according to protection class.

• Do not mount the flow sensor where vibration (98m/s

2

or less) and

impact (490m/s

2

or less) do not exist to avoid failure and malfunction.

• Operation under low temperature (5 or less) leads to cause damage

or operation failure due to frozen moist in the fluid or air.

• Do not short circuit the load.

• Supply power when there is no flow.

• The flow sensor is compulsory turned off for 3s after power supplied.

• Maintenance and inspection should be performed periodically.

• Analogue output may fluctuate by 2 to 3% for 10 minutes after

supplying power to the flow sensor.

• Do not poke inside a piping port with a stick.

• A flow rate of the flow sensor, which has a restrictor, may change if the

needle turns due to vibration.

• The accuracy may fluctuate by 2 to 3% if a customer removes or

replaces piping by themselves.

• When the product is fixed with a screw using the through hole, please

tighten it with a 0.3Nm ± 0.05 or less of tightening torque. (Excessive

tightening may break the product.)