Torque data chart, Warning – Stellar Industries 28000 User Manual

Page 14

10

28000 Owner’s Manual

Holding Valve Inspection Procedure

The cylinders are equipped with holding

valves that prevent sudden movement of

the cylinder rods in the event of a hydraulic

hose or hydraulic component failure. The

valve is checked in the following manner:

1. Identify the cylinder in question.

2. Identify the holding valves and the

cylinder direction in question.

a. Cylinder Extend.

b. Cylinder Retract.

3. Place the machine so that the cylinder

will be located in the appropriate testing

position.

4. Pick the load (Do not exceed capacity,

rated or stability).

5. Disengage hydraulics.

6. Operate crane functions.

A. If the cylinder creeps (lowering the

load), replace the holding valve.

B. If the cylinder does not creep (load

stays suspended), the valve is

operational.

Gear-Bearing Bolt Maintenance

Anytime a gear-bearing bolt is removed, it

must be replaced with a new bolt of the

identical grade and size. Once a bolt has

been torqued to 75% of its proof load and

then removed, the torque coefficient may

no longer be the same as when the bolt was

new thus giving indeterminate damp loads

after torquing.

Warning!

Failure to replace gear-bearing

bolts may result in bolt failure due

to metal fatigue causing serious

injury or even death.

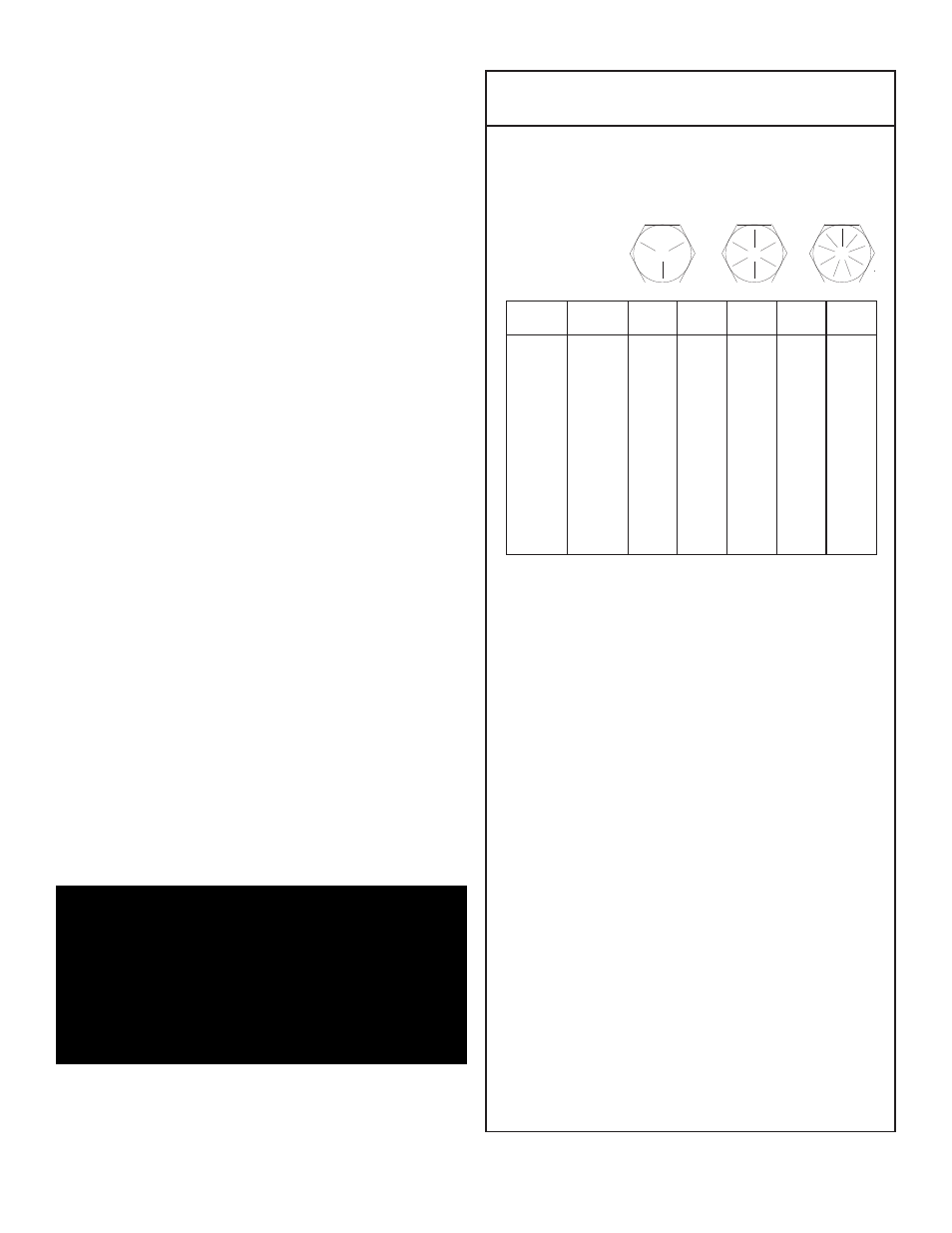

Torque Data Chart

Note: For Crane Tie Down Rods, see

Chapter 6: Installation Overview.

When using the torque data in the charts

above, the following rules should be

observed.

1. Bolt manufacturer’s particular

specifications should be consulted when

provided.

2. Flat washers of equal strength must be

used.

3. All torque measurements are given in

foot-pounds. To convert to inch-pounds,

multiply by 12.

4. Torque values specified are for bolts with

residual oils or no special lubricants

applied. If special lubricants of high stress

ability, such as Never-Seez compound

graphite and oil, molybdenum disulphite,

colloidal copper or white lead are

applied, multiply the torque values in the

charts by the factor .90. The use of Loctite

does not affect the torque values listed

above.

5. Torque values for socket-head capscrews

are the same as for Grade 8 capscrews.

Plated

(Ft-Lb)

22

39

63

96

139

192

340

549

823

1167

1646

2158

2865

Plated

(Ft-Lb)

18

33

52

80

115

160

280

455

680

965

1360

1780

2370

Plain

(Ft-Lb)

25

44

70

105

155

220

375

605

910

1290

1815

2380

3160

Plated

(Ft-Lb)

13

23

37

57

82

115

200

295

445

595

840

110

1460

Plain

(Ft-Lb)

17

31

49

75

110

150

265

395

590

795

1120

1470

1950

Bolt DIA

(Inches)

0.3125

0.3750

0.4375

0.5000

0.5625

0.6250

0.7500

0.8750

1.000

1.1250

1.2500

1.3750

1.500

Size

(DIA-TPI)

5/16-18

3/8-16

7/16-14

1/2-13

9/16-12

5/8-11

3/4-10

7/8-9

1-8

1 1/8-7

1 1/4-7

1 3/8-6

1 1/2-6

Grade 5

Grade 8

Grade 9