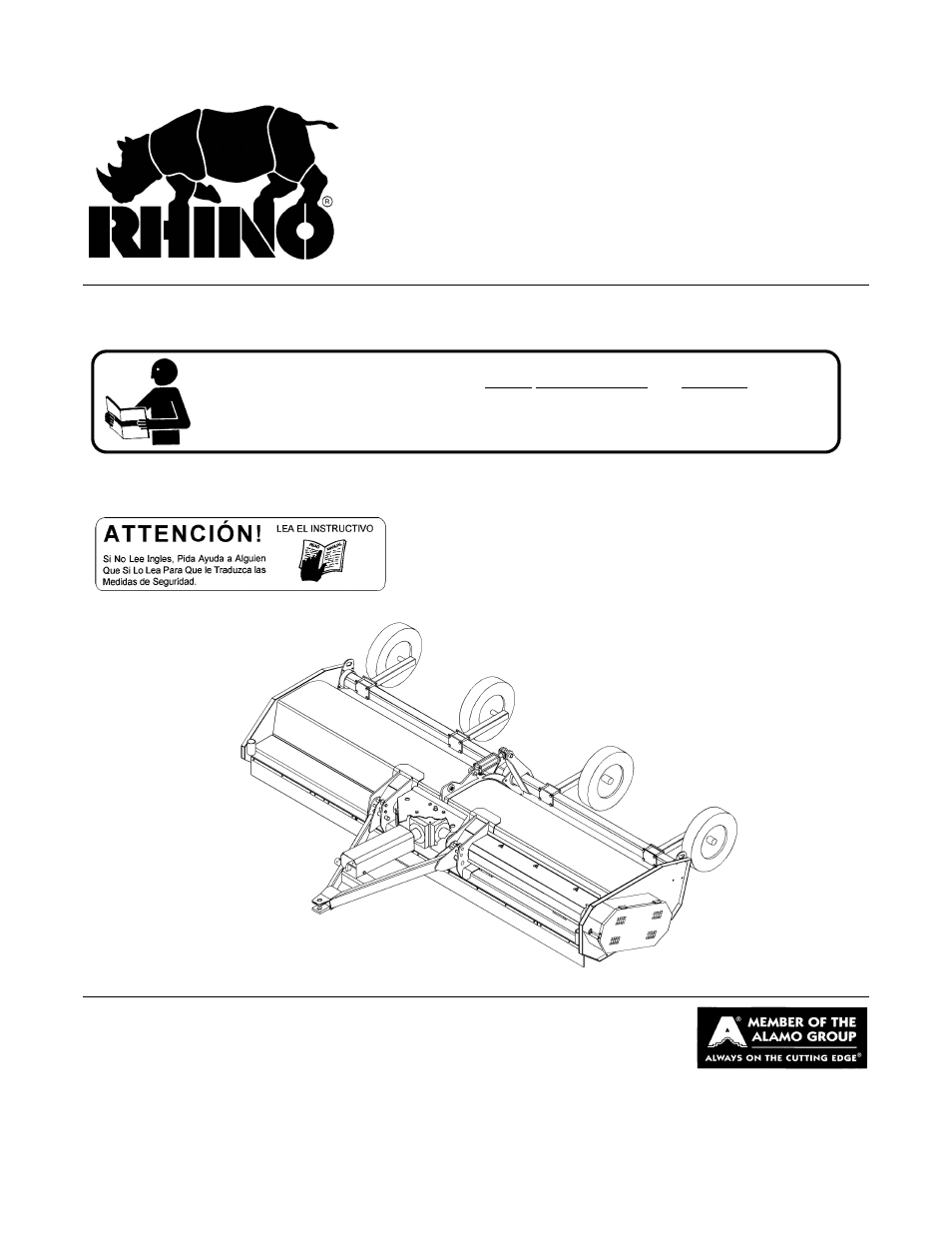

Servis-Rhino RC-12 User Manual

Rc-12, Operator’s manual, Flail shredder

©2006 Alamo Group Inc.

$0.00

Published 12/05

Effective Serial No. RC-12-10040 through current Part No. 00726339C

OPERATOR’S MANUAL

RHINO

®

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: [email protected]

FLAIL SHREDDER

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

RC-12

Table of contents

Document Outline

- RC-12

- OPERATOR’S MANUAL

- To the Owner/Operator/Dealer

- TABLE OF CONTENTS

- SAFETY SECTION 1-1

- INTRODUCTION SECTION 2-1

- ASSEMBLY SECTION 3-1

- OPERATION SECTION 4-1

- MAINTENANCE SECTION 5-1

- General Safety Instructions and Practices

- Equipment Operation Safety Instructions and Practices

- Connecting or Disconnecting Implement Safety Instructions and Practices

- Maintenance and Service Safety Instructions and Practices

- Concluding Safety Instructions and Practices

- 1 002369 1 DANGER Flail Multi-Hazard

- 2 00725739 1 WARNING Use/Repair Shields & Guards

- 3 999001 1 WARNING Maintain Weight for Steerage

- 4 00725746 1 PELIGRO Spanish - Get Translation

- 5 00756004 3((1)) DANGER Driveline Shield Missing

- 6 00756005 3((1)) DANGER Rotating Driveline

- 7 02967668 1 DANGER Cutting Blades / Thrown Objects

- 8 00756059 1 WARNING Leak Detection, Oil Penetration

- 9 00756494 1 DANGER Driveline Safety

- 10 00758194 1 WARNING Pitch Point (V-Belt/Pulley)

- 11 03200347 *1 REFLECT SMV Reflector

- 12 1458392 {2} REFLECT Red Reflector

- 13 1458393 {2} REFLECT Yellow Reflector

- 14 00725747 1 INSTRUCT RC Flail Operating Instructions

- 15 000678 2(4) INSTRUCT Grease Fitting Inside

- 16 00725713 1 INSTRUCT Lubrication Chart, RC Flails

- 17 00725738 1 INSTRUCT Notice to Owner

- 18 00725715 2 INSTRUCT Pick Up From Lift Points Only

- 19 00725720 1 INSTRUCT Belt Adjustment

- 20 00725745 1 INSTRUCT Quick Coupler Hitch Only

- 21 02964510 1 IMPORTANT Genuine Parts, Flail

- 22 00773723 1 PELIGRO Rotating Driveline Translation

- 23 NFS 4 SER PLT Serial Plate

- 24 D302 2 LOGO RHINO LOGO (4-7/8 x 6-1/2)

- 25 D303 2 L. NAME RHINO (4-3/8 x 16-1/2)

- 26 00725626 1 MODEL RC12

- 27 D114 1 WARNING 1000 RPM PTO

- 28 00763977 1 INSTRUCT Notice to Owner

- 29 00771283 1 INSTRUCT 5 Year Warranty

- 30 00775933 1 WARNING Guard Missing

- 31 D102 1 INSTRUCT PTO-to-Drawbar Adj. Safety Chain

- 32 00776481 1 INSTRUCT Operators Manual Inside (Decal)

- 33 00776031 1 ________ Canister, Operators Manual

- 34 00726339C 1 ________ Operators Manual

- 35 10058000 3 ________ Bolt

- 36 00024100 6 ________ Flatwasher

- 37 02959924 3 ________ Locknut

- SAFETY SECTION

- Decal Description

- Federal Laws and Regulations

- ATTENTION OWNER/OPERATOR

- SHIPPING STAND REMOVAL

- BREATHER PLUG INSTALLATION

- TONGUE ASSEMBLY INSTALLATION

- 3-POINT HITCH ASSEMBLY INSTALLATION

- ATTACHING AXLE ASSEMBLIES TO MAIN WHEEL BAR TUBE

- RHINO RC12 FLAIL SHREDDER OPERATION INSTRUCTIONS

- 1. Standard Equipment and Specifications

- 2. OPERATOR REQUIREMENTS

- 3. GETTING ON AND OFF THE TRACTOR

- 4. STARTING THE TRACTOR

- 5. CONNECTING THE MOWER TO THE TRACTOR

- 6. SETTING THE MOWER

- 1. Place the tractor and mower on a level surface and completely lower the mower to the ground.

- 2. Shut down the tractor, place the transmission in park, and set the parking brake before dismounting.

- 3. One section at a time, place lifting device (scissors jack or hydraulic jack) under center of cutter housing.

- 4. Remove hex nuts, washers and carriage bolts from bracket at each end of roller. Make certain that roller bracket is free to move once the fasteners are removed. A stuck roller could drop unexpectedly and cause injury.

- 5. Use lifting device to reposition cutter housing to desired cutting height. Align bracket holes with cutter housing, then reinstall hardware.

- 6. Lower cutter housing to the ground and remove lifting device.

- 7. Set cutting height according to procedures above for remaining two cutter sections. Make sure that all three rollers are set at the same height to ensure a even cut across the entire width of the mower.

- 6.1 Leveling Deck

- 7. DRIVELINE ATTACHMENT

- 8. PRE-OPERATION INSPECTION AND SERVICE

- 9. DRIVING THE TRACTOR AND IMPLEMENT

- 10. OPERATING THE TRACTOR AND IMPLEMENT

- 11. DISCONNECTING THE MOWER FROM THE TRACTOR

- 12. MOWER STORAGE

- 13. TRANSPORTING THE TRACTOR AND IMPLEMENT

- 13.1 Transporting on Public Roadways

- 13.2 Hauling the Tractor and Implement

- Problem Possible Cause Remedy

- Check for missing knives on Replace missing knives

- cutter shaft.

- Check to see if knives are Free knives so they swing.

- free swinging.

- Blade broken or bent. Replace blades.

- Cuttershaft bent. Replace cuttershaft.

- Drivelines not phased correctly. Replace driveline.

- Implement & Tractor yokes must

- be in line.

- Cuttershaft bearing worn Replace bearings

- Improper type lubricant. Replace with proper lubricant.

- Excessive trash build-up Remove trash.

- around gearbox.

- Bearing or gears set up Consult your Dealer.

- improperly.

- Worn Bearing. Replace bearing.

- (Rubbing on pulleys or belt).

- Worn Bearing or Gear. Replace Bearing or Gear.

- Bent shaft. Replace oil seal and shaft.

- Shaft rough in oil seal area. Replace or repair shaft.

- Oil seal installed wrong. Replace seal.

- Oil seal not sealing in the housing. Replace seal or use a sealant on

- OD of Seal.

- Oil level too high. Drain oil to proper level.

- Sand hole is casting. Replace castings or gearbox.

- Gasket damaged. Replace gasket.

- Bolts loose. Tighten bolts.

- Clutch Slips Excessively Clutch linings badly worn or Repair clutch per maintenance

- plates warped. section of manuals.

- Too much power for clutch. Reduce ground speed and material

- intake.

- Oil on facings. Replace facings.

- Friction facings glazed. Clean with emery cloth.

- Cutting in rocky conditions. Increase cutting height.

- Soft “will fit” knives. Use genuine Rhino knives.

- Blades dull. Check blades for sharpness.

- Grass too wet. Wait for grass to dry.

- Grass too long. Mow at 3-1/2” and recut lower.

- Travel speed too fast. Use a lower tractor gear.

- PTO RPM too low. Mow at engine RPM to match 540

- PTO RPM.

- Rough, uneven ground. Use a slower speed.

- Lower rollers.

- Turning Tractor too fast. Slow down when turning.

- Mower deck not level. Level the mowing deck.

- Blades dull or unbalanced. Sharpen or balance blades.

- Deck underside plugged. Clean underside of deck.

- Grass too high. Mow at 3-1/2” and recut lower.

- Housing plugged. Clean underside of deck.

- Spring broke & belt off idler. Replace spring or adjust belt.

- Housing plugged. Clean underside of housing.

- Debris around pulleys. Remove deck belt shield and clean

- out debris.

- Grass too high. Mow at 3-1/2” and recut lower.

- OPERATION SECTION

- MAINTENANCE SECTION

- Problem Possible Cause Remedy

- GENERAL MAINTENANCE

- LUBRICATION

- ROUTINE MAINTENANCE:

- CUTTER SHAFT

- BLADE REPLACEMENT

- BELT ADJUSTMENT AND REPLACEMENT

- 1. Standard Equipment and Specifications

- PULLEY ALIGNMENT AND REMOVAL

- CUTTER SHAFT AND BEARING REMOVAL

- DRIVELINE:

- STORING THE RC12

- 1. Check the oil level in the Gearbox and lubricate all bearings. See "Lubrication".

- 2. Adjust drive belt tension. See "Belt Drive".

- 3. Inspect for missing and / or broken Blades / Knives. Replace as necessary. See "Knife Replacement".

- 4. Be sure that the Safety Guard is in place and secure.

- 5. Run the Orchard at a low RPM checking to make sure that all driveline parts are moving freely.

- TO THE OWNER/OPERATOR/DEALER

- RHINO

- LIMITED WARRANTY

- 1. LIMITED WARRANTIES

- 1.01. Rhino warrants for one year from the purchase date to the original non-commercial, governmental, or municipal purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser

- 1.02. Manufacturer will replace for the Purchaser any part or parts found, upon examination at one of its factories, to be defective under normal use and service due to defects in material or workmanship.

- 1.03. This limited warranty does not apply to any part of the goods which has been subjected to improper or abnormal use, neglig...

- 1.04. Except as provided herein, no employee, agent, Dealer, or other person is authorized to give any warranties of any nature on behalf of Manufacturer.

- 2. REMEDIES AND PROCEDURES.

- 2.01. This limited warranty is not effective unless the Purchaser returns the Registration and Warranty Form to Manufacturer within 30 days of purchase.

- 2.02. Purchaser claims must be made in writing to the Authorized Dealer (“Dealer”) from whom Purchaser purchased the goods or an approved Authorized Dealer (“Dealer”) within 30 days after Purchaser learns of the facts on which the claim is based.

- 2.03. Purchaser is responsible for returning the goods in question to the Dealer.

- 2.04. If after examining the goods and/or parts in question, Manufacturer finds them to be defective under normal use and service due to defects in material or workmanship, Manufacturer will:

- (a) Repair or replace the defective goods or part(s) or

- (b) Reimburse Purchaser for the cost of the part(s) and reasonable labor charges (as determined by Manufacturer) if Purchaser paid for the repair and/or replacement prior to the final determination of applicability of the warranty by Manufacturer.

- 2.05. Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by Manufacturer and for returni...

- 3. LIMITATION OF LIABILITY.

- 3.01. MANUFACTURER DISCLAIMS ANY EXPRESS (EXCEPT AS SET FORTH HEREIN) AND IMPLIED WARRANTIES WITH RESPECT TO THE GOODS INCLUDING, BUT NOT LIMITED TO, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

- 3.02. MANUFACTURER MAKES NO WARRANTY AS TO THE DESIGN, CAPABILITY, CAPACITY, OR SUITABILITY FOR USE OF THE GOODS.

- 3.03. EXCEPT AS PROVIDED HEREIN, MANUFACTURER SHALL HAVE NO LIABILITY OR RESPONSIBILITY TO PURCHASER OR ANY OTHER PERSON OR ENTI...

- 3.04. NO ACTION ARISING OUT OF ANY CLAIMED BREACH OF THIS WARRANTY OR TRANSACTIONS UNDER THIS WARRANTY MAY BE BROUGHT MORE THAN TWO (2) YEARS AFTER THE CAUSE OF ACTION HAS OCCURRED.

- 4. MISCELLANEOUS.

- 4.01. Proper Venue for any lawsuits arising from or related to this limited warranty shall be only in Guadalupe County, Texas.

- 4.02. Manufacturer may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall be deemed to be a waiver of any other term.

- 4.03. If any provision of this limited warranty shall violate any applicable law and is held to be unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

- 4.04. Applicable law may provide rights and benefits to purchaser in addition to those provided herein.