Assembly, Emission control (exhaust & evaporative) – Shindaiwa GP344 User Manual

Page 5

5

Before assembling this unit, make sure

you have all the components required

for a complete unit:

GP344 engine-driven pump

■

Spark plug wrench

■

Spanner

■

3mm Hex Wrench

■

4mm Hex Wrench

■

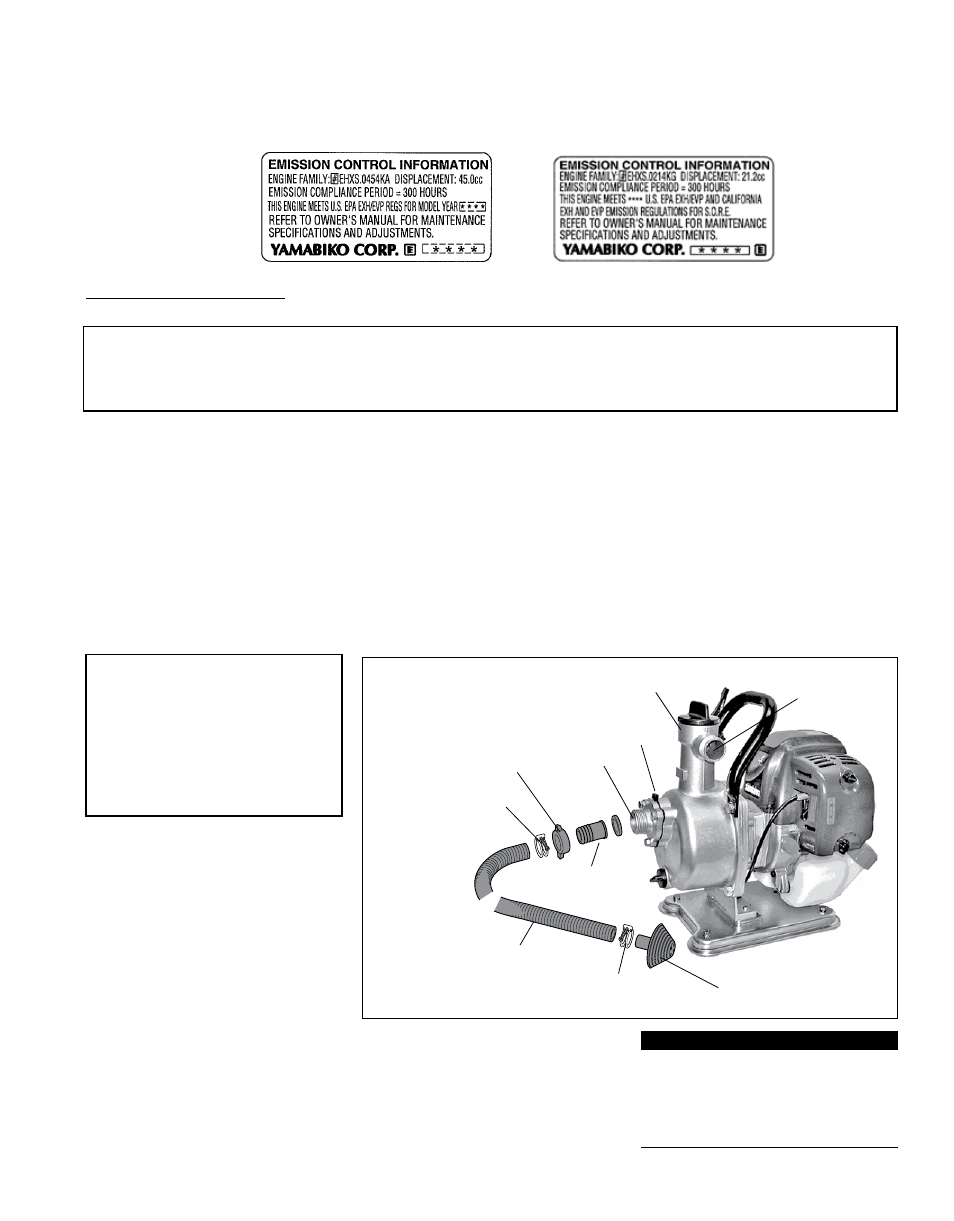

Assemble a barbed hose fitting,

1.

ring nut, and gasket as shown, and

thread the completed hose fitting

assembly onto the pump suction

port.

Push a 1.0" suction hose (not pro-

2.

vided) over the suction hose fitting on

the pump body, and secure with a 1.0"

hose clamp as shown. Working at the

opposite end of the suction hose, use

a second 1.0" hose clamp to install and

secure the suction strainer.

Submerge the suction hose strainer

3.

in the water source. For maximum

performance, avoid placing the

strainer directly in heavy accumula-

tions of leaves, silt, or other debris.

Suction

Hose

Suction

Strainer

Hose Clamp

Barbed Hose

Fitting

Hose Clamp

Ring Nut

Gasket

Suction Port

Discharge Port

Install the discharge hose (not

4.

provided) using the garden hose

adapter.

Recheck that both the suction and

5.

discharge hoses are free from

obstructions, and that all connec-

tions are tightly secured.

Assembling the hoses

Priming Port

Parts bag including:

■

1.0" hose clamps (3 each)

■

hose fittings and gaskets

■

(2 each)

strainer

■

garden hose adapter (use gar-

■

den hose only to discharge

water!)

Prior to Assembly

Assembly

Install the Suction and discharge hoses

CAUTION!

This pump is intended for pump-

■

ing fresh water only.

Ingested debris can damage the

■

pump impeller and seals.

Never operate the pump if the

■

strainer is missing or damaged.

IMPORTANT!

Place the pump as close to the water

source as possible. Increases in suc-

tion lift will lower pump performance.

Do not exceed maximum suction head

of 26 feet.

An Emission Control Label is located on the unit. (This is an EXAMPLE ONLY; information on label varies by en-

gine FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine

emissions output meets applicable emissions regulations, provided that approved maintenance procedures are

followed as listed in the Maintenance Section of this manual.

Emission Control (Exhaust & Evaporative)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modification and 3-way Catalyst) and for the fuel tank

the Control System is EVAP (Evaporative Emissions) or N (for nylon tank). Evaporative emission may be applicable to

California models only.